Torque control method for preventing backward slipping of blade electric vehicle on slope

A pure electric vehicle and torque control technology, applied in the field of electric control system control of new energy vehicles, can solve problems such as slopes and slopes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following is attached figure 1 , figure 2 and image 3 Describe in detail the specific implementation process of the present invention:

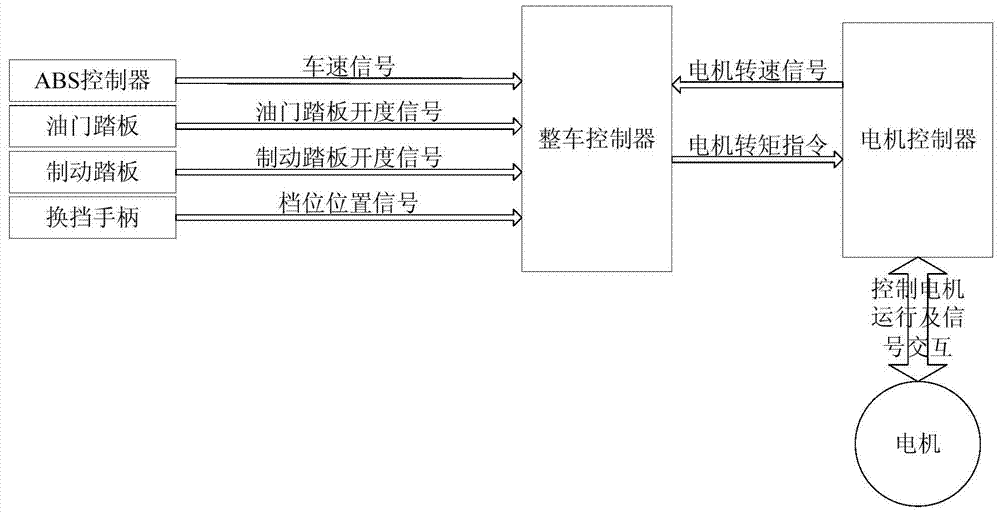

[0018] see figure 1 , it can be seen from the control system diagram of the electric vehicle to prevent the slope from slipping, the vehicle controller obtains corresponding signals from the ABS controller, the accelerator pedal, the brake pedal, and the shift handle from various sensors, and then Through the following judgment and calculation method, finally send the motor torque command to the motor controller to control the operation of the motor.

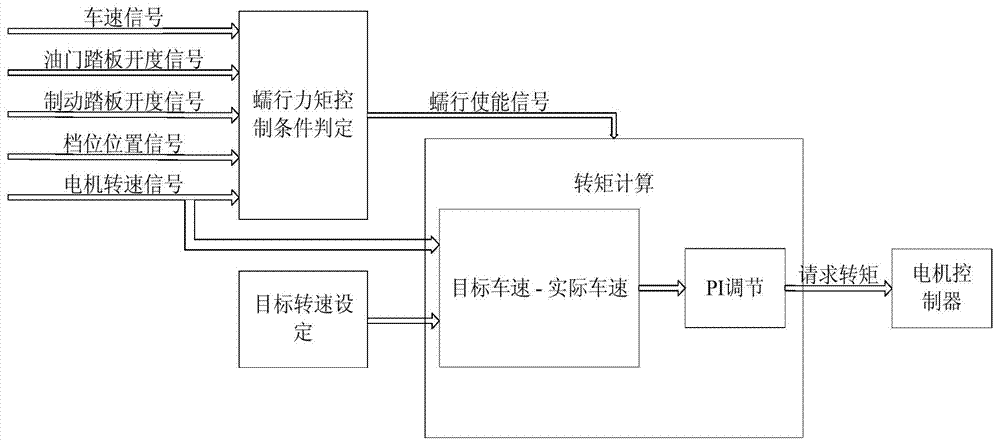

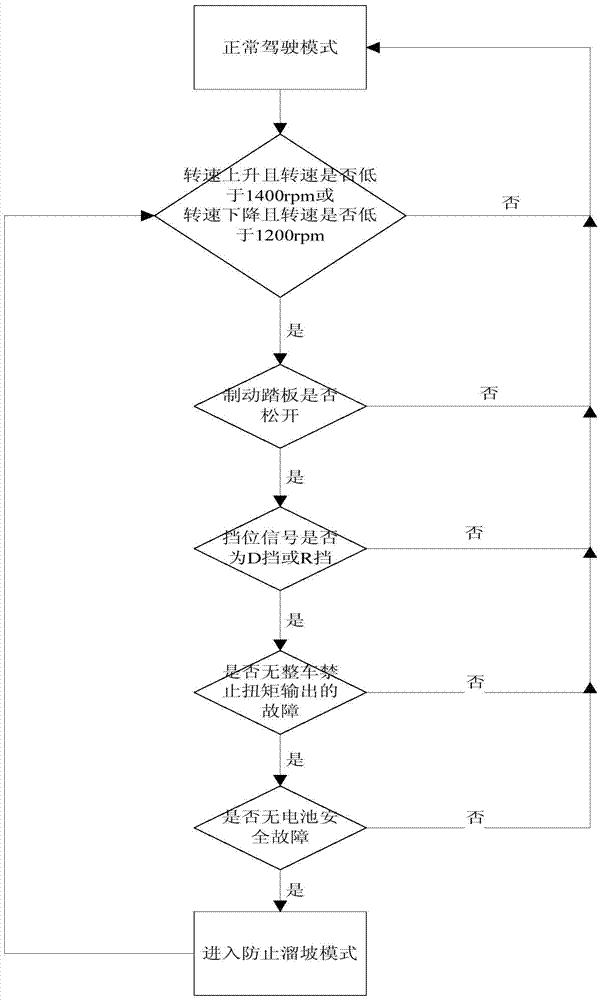

[0019] see figure 1 and image 3 , the specific control steps are as follows:

[0020] 1. The vehicle controller (VCU) first judges whether the state of the vehicle should enter the anti-slip state according to the accelerator pedal opening, brake pedal information, gear information, motor speed, vehicle speed provided by ABS, and vehicle fault status. Slope control mode, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com