Friction type wire rod rust removal tool

A friction type, tooling technology, applied in the direction of manufacturing tools, metal processing equipment, grinding machines, etc., can solve the problems of environmental pollution, high cost, high noise, etc., and achieve the effect of wide application range, high work efficiency and stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

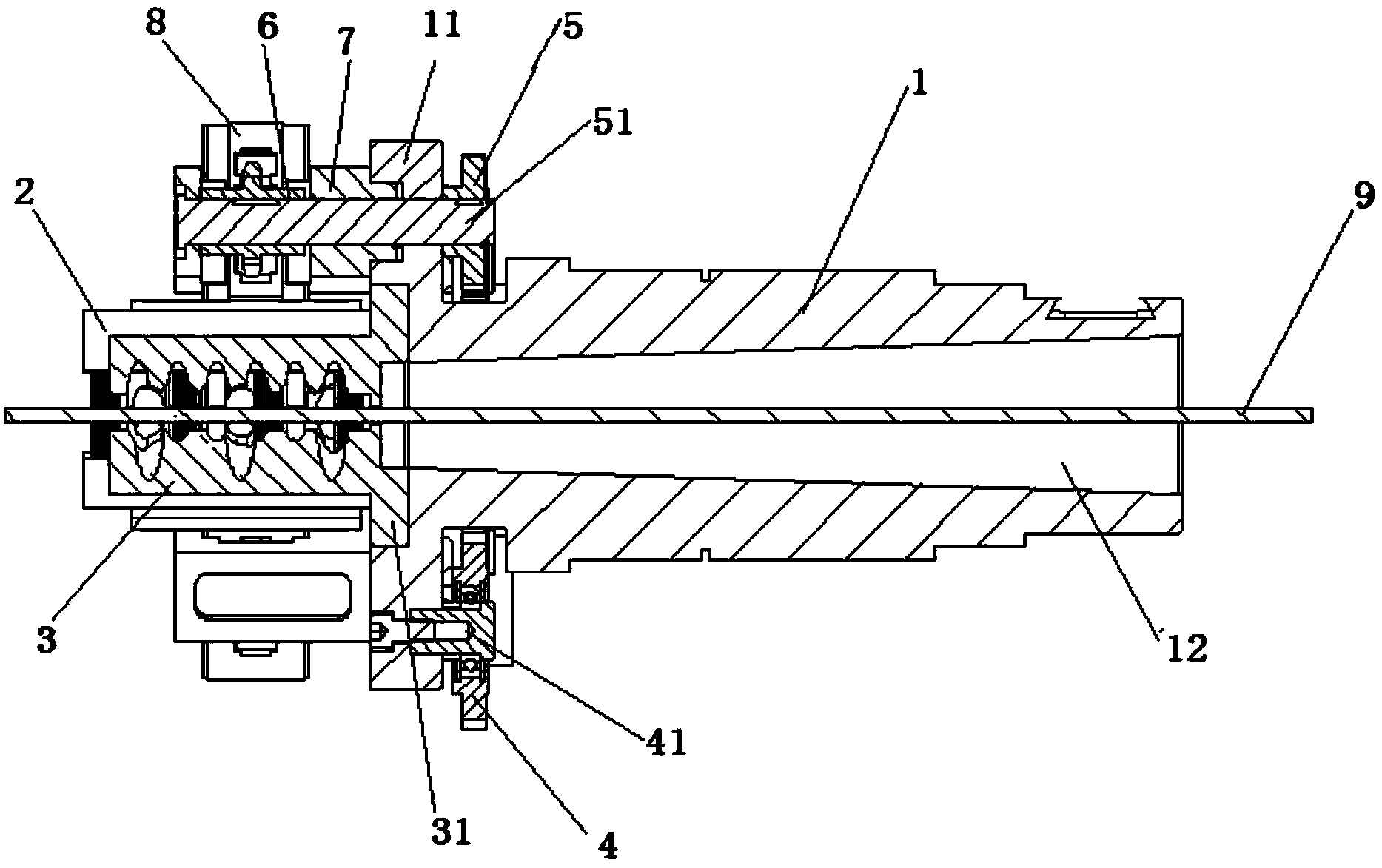

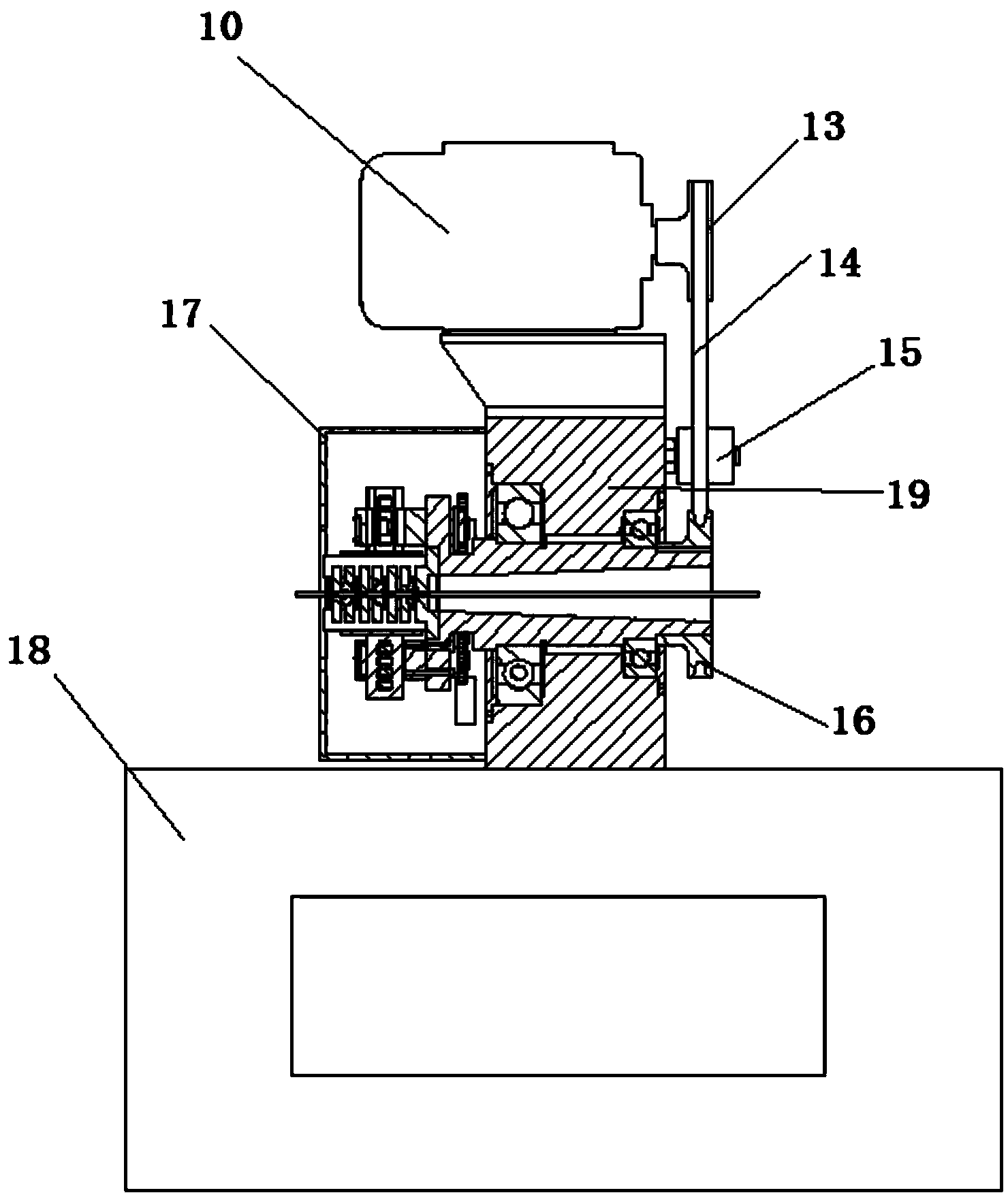

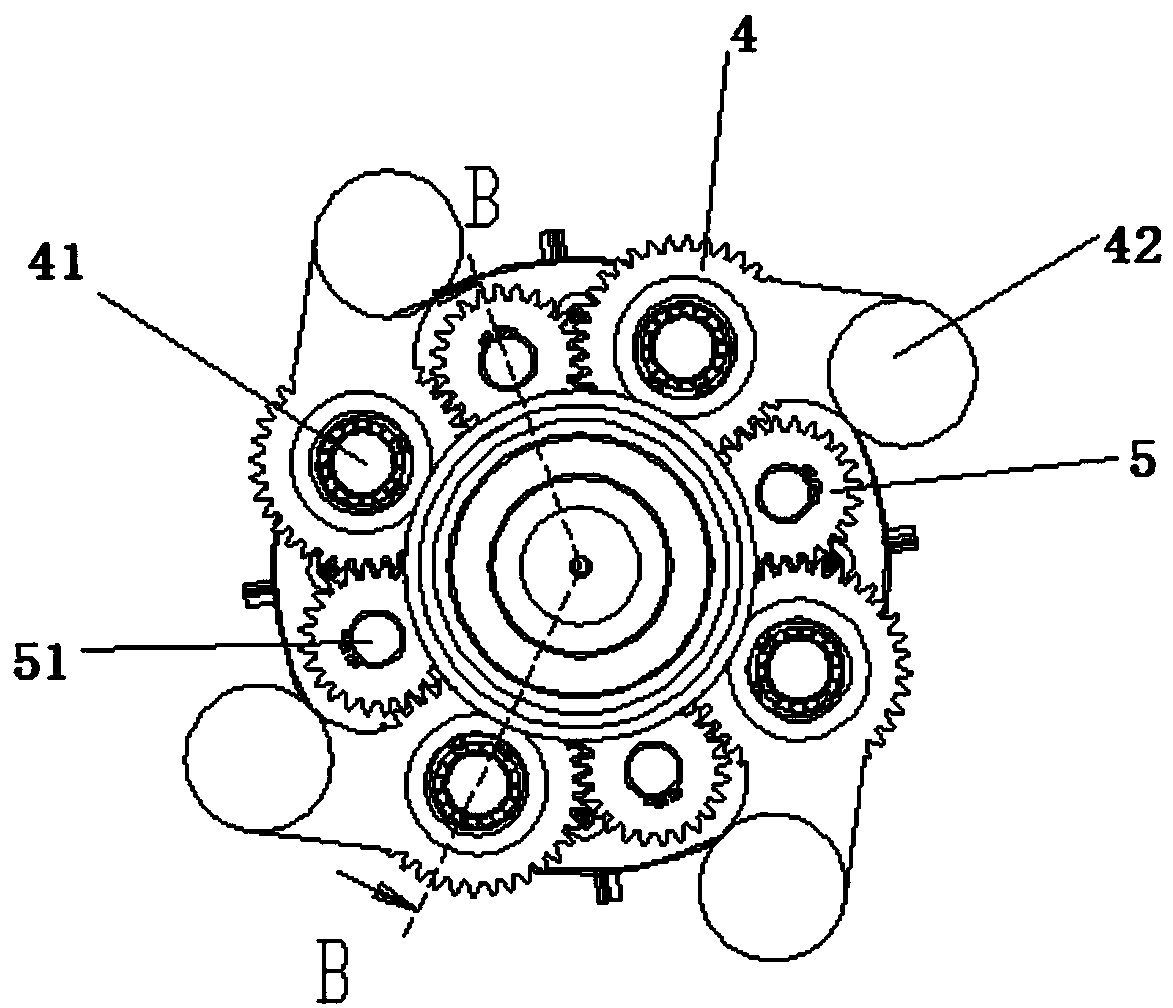

[0033] Such as figure 1 As shown, the present invention provides a friction type wire rod derusting tool, including a main shaft 1, four elongated wire brushes 2, an open groove shaft 3, a transmission mechanism and a brush body internal pressure mechanism;

[0034] Such as Figure 5 , Figure 6 As shown, the main shaft 1 is a hollow shaft, one end of which has a main shaft flange 11, and the inside has a hole penetrating in the axial direction;

[0035] Such as Figure 7 , Figure 8 As shown, the open slotted shaft 3 is also a hollow shaft, one end of which has an open slotted shaft flange 31, and the inside has an axially through hole. An open slot 32, the open slot 32 runs through the two end surfaces of the open slot shaft 3 and the axially through hole inside the open slot shaft 3, and one end of the open slot shaft 3 has an open slot shaft flange 31;

[0036] The long steel wire brush 2 is located in the open groove 32, and one end of the long steel wire brush 2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com