Supporting device for coal mine drill pipe threading

A technology for supporting device and drill pipe, which is applied in the direction of tangent device, workbench, metal processing equipment, etc., can solve the problems of wear, high labor intensity of operators, and insecurity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

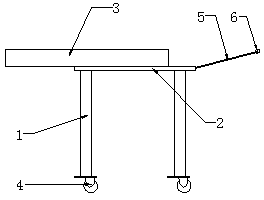

[0010] The coal mine drill pipe over-wire supporting device of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0011] As shown in the figure, the coal mine drill pipe threading support device of the present invention includes four hydraulic columns 1 that can be lifted. The upper end of the hydraulic column 1 is provided with a support platform 2. The bottom end of column 1 is provided with the universal wheel 4 that is convenient for walking,

[0012] When in use, firstly, lower the hydraulic column to place the drill pipe on the support platform 2 and pass through the drill pipe casing 3, then raise the hydraulic column to the height of the wire passing equipment, and then use the wire passing equipment to carry out the wire passing process. The quality of the drill pipe threading is improved, the labor intensity is reduced, and the unsafe factors in the threading production are reduced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com