Dryer and drying device as well as pressing mould and preparation process of dryer

A technology for pressing molds and drying devices, which is applied in the direction of manufacturing tools, presses, and separation of dispersed particles. It can solve the problems of low dehumidification efficiency, calcium chloride is not easy to carry and store, and is not easy to use. It achieves various appearance colors and high moisture absorption efficiency. , High water absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 8

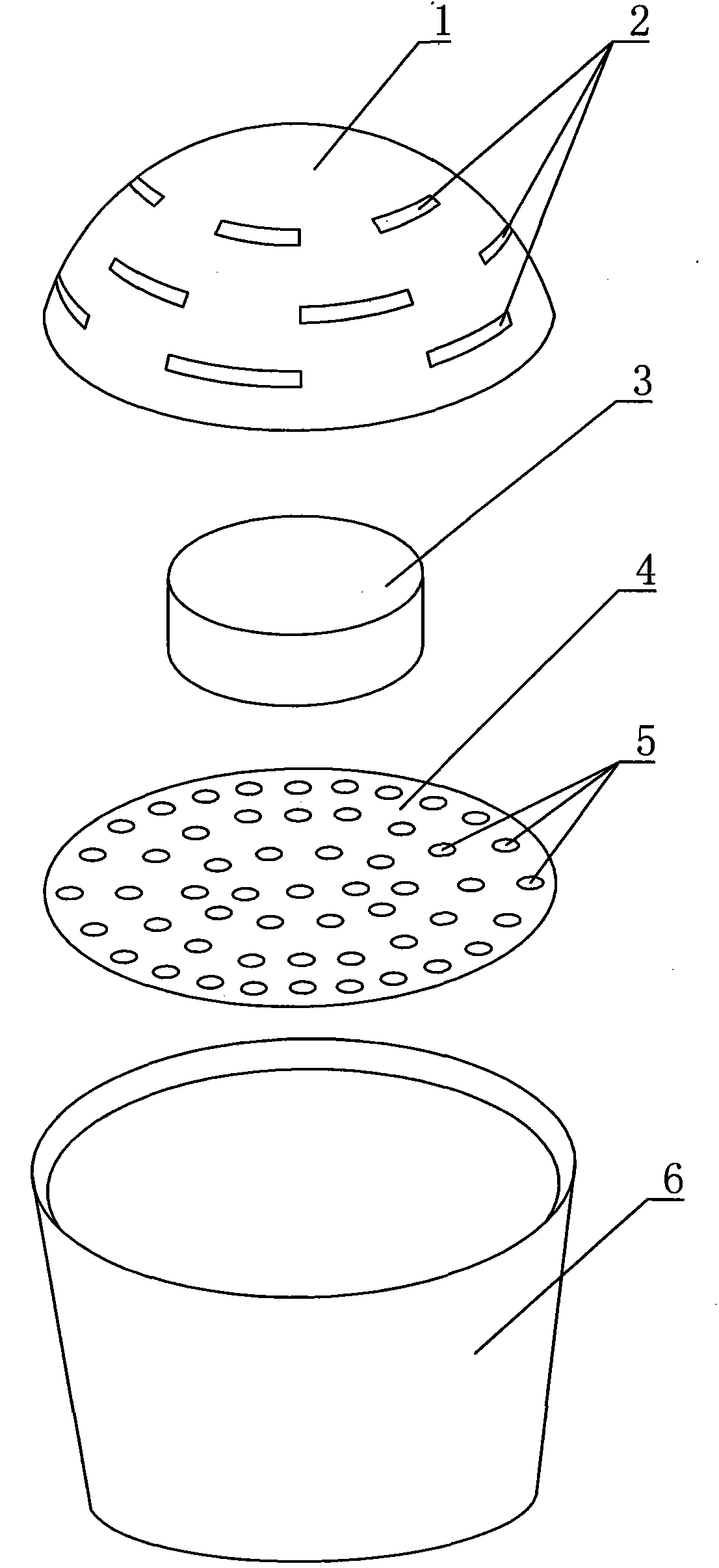

[0029] Embodiment 8: as attached figure 1 As shown, a drying device includes a water receiving basin 6 on which a partition 4 is arranged. When in use, place a large desiccant 3 on the partition 4 . The main component of bulk desiccant 3 is calcium chloride. Calcium chloride can gradually liquefy after absorbing water and fall into the water receiving basin. The desiccant that has not been liquefied will remain on the partition to continue to exert a strong moisture absorption capacity.

[0030] as attached figure 1 Shown, the dividing plate 4 of drying device is provided with leak hole 5, also can change into leak groove etc. certainly.

[0031] as attached figure 1 As shown, the water receiving basin 6 of the drying device is provided with a basin cover 1, and the basin cover 1 is provided with a ventilation groove 2, and of course, it can also be changed into a ventilation hole. When the bulk desiccant 3 absorbs the moisture in the air, the main component calcium chlori...

Embodiment 9

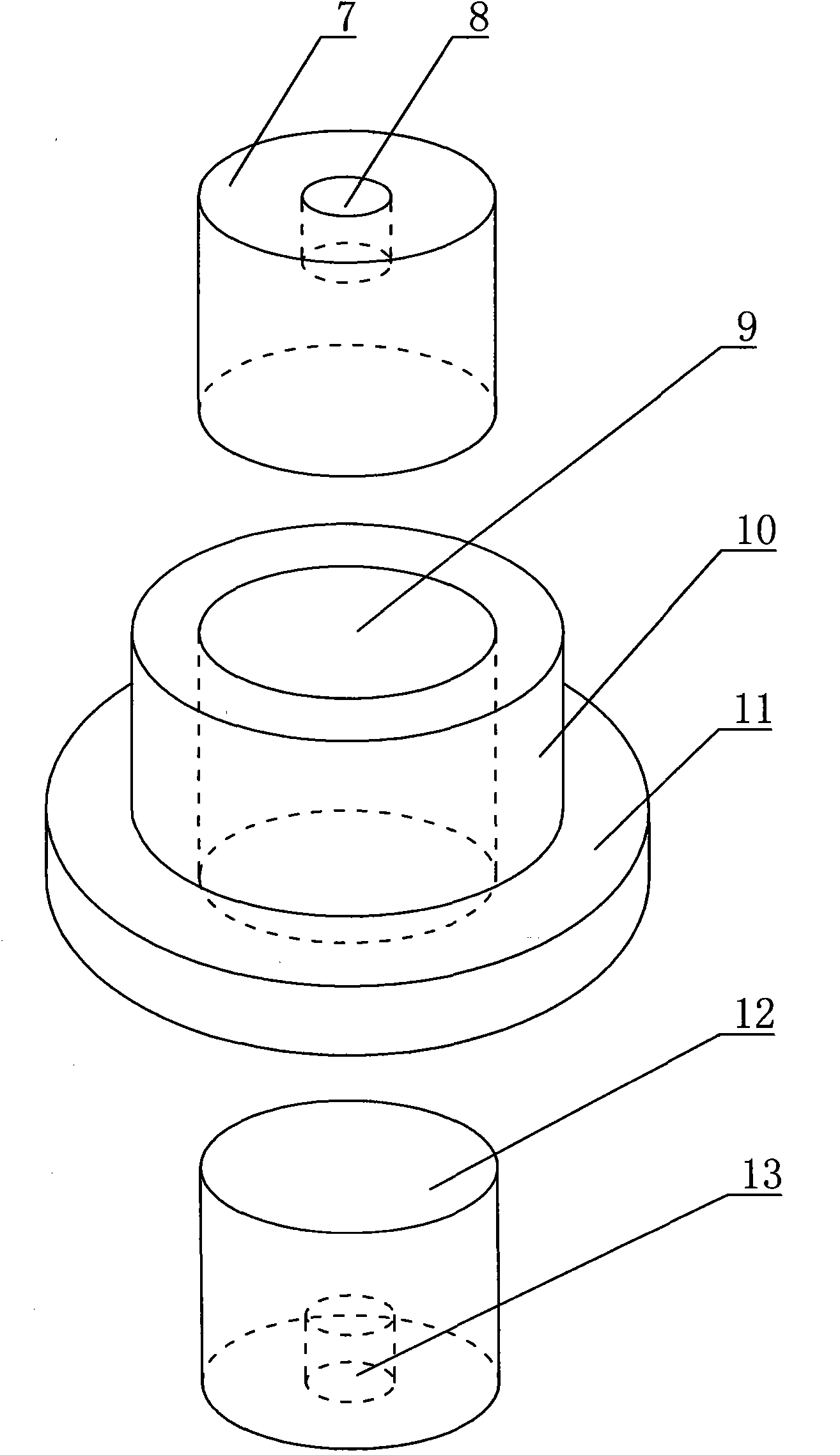

[0032] Embodiment 9: as attached figure 2 As shown, the desiccant pressing mold includes an upper mold 7, a middle mold 10 and a lower mold 12. The upper mold 7 is a columnar body, and the middle mold 10 is provided with a through hole 9 matching the outer dimension of the upper mold 7. The lower mold 12 is a columnar body matched with the through hole 9 of the middle mold 10 . Wherein, the lower edge of the middle mold 10 is provided with a circumferentially protruding fixed edge 11, to fix the middle mold 10, the top of the upper mold 7 is provided with an upper threaded hole 8, and the bottom of the lower mold 12 is provided with a lower threaded hole 13, and the upper thread The hole 8 is connected with the hydraulic rod of the upper hydraulic cylinder of the lathe, and the lower threaded hole 13 is connected with the hydraulic rod of the lower hydraulic cylinder of the lathe.

[0033] Use steps: fix the middle mold 10 on the workbench of the lathe through the fixed edge...

Embodiment 10

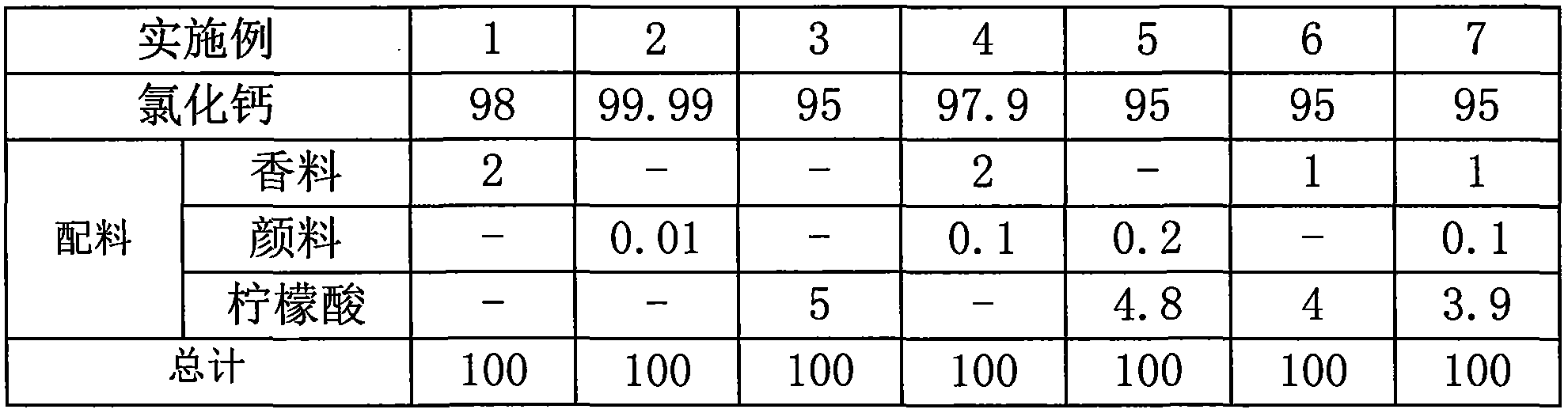

[0035] Embodiment 10: the production technology of desiccant, comprises the following steps:

[0036] Step 1: Weigh the raw materials of each component, mix them according to the weight percentage, and stir evenly to form a premix;

[0037] Step 2: Weigh the premix of fixed weight;

[0038] Step 3: Put the weighed fixed weight premix into the block desiccant pressing mold;

[0039] Step 4: Compress the premix to form a block;

[0040] Step 5: Demould the compressed desiccant and blow it manually.

[0041] Step 6: Vacuum packing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com