A kind of processing method of precipitation-free tomato juice

A processing method and technology for tomato juice, applied in the processing field of tomato juice without precipitation, can solve problems such as precipitation and insufficient solution, and achieve the effects of avoiding green taste, avoiding the increase of cooked taste, and reducing the destruction of nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) A total of 7Kg of raw tomato powder 802 and Fenkui are cleaned. First, cut the flaps and put them into a medium-sized cymbal crushing juicer with cymbals inside to squeeze the juice. After the tomato juice is filtered, it is squeezed out. Add 3Kg of water to the original tomato juice to obtain tomato juice;

[0022] (2) Heat the tomato juice at 65°C for 2 minutes, and then squeeze it with 100 mesh gauze;

[0023] (3) Add sugar, salt and vitamin C to the filtered tomato juice according to the formula. The mass percentage of sugar is 4%, the mass percentage of salt is 0.5%, the mass percentage of vitamin C is 0.02%, and the rest is tomato juice It is then homogenized by a high-pressure homogenizer, and sterilized by Bath at 75°C for 18 minutes after bottling. After cooling, the product can be obtained without precipitation tomato juice.

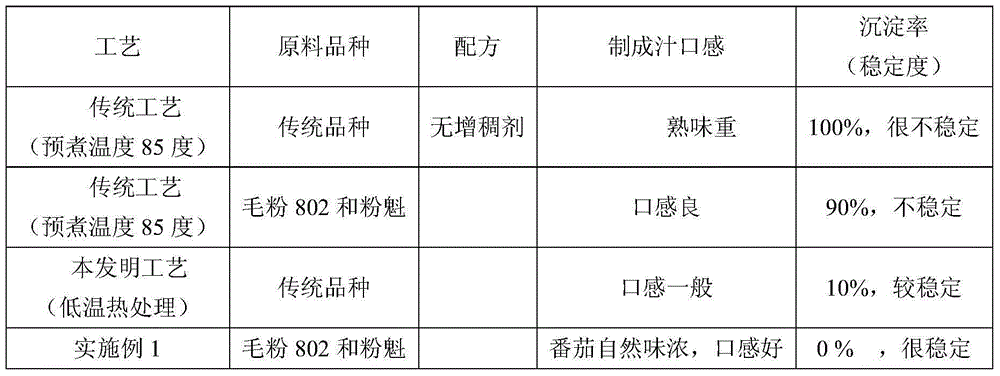

[0024] Comparison of the product of Example 1 without precipitation tomato juice and traditional process varieties:

[0025]

Embodiment 2

[0027] (1) A total of 7Kg of raw tomato powder 802 and Fenkui are cleaned. First, cut the flaps and put them into a medium-sized cymbal crushing juicer with cymbals inside for squeezing. Add 1Kg to the squeezed tomato juice. Water to get tomato juice;

[0028] (2) Heat the tomato juice at 75℃ for 4 minutes, then squeeze it with a 200-mesh gauze;

[0029] (3) Add sugar, salt, and vitamin C to the filtered tomato juice according to the formula, where the mass percentage of sugar is 5%, the mass percentage of salt is 1%, the mass percentage of vitamin C is 0.03%, and the rest is tomato juice It is then homogenized by a high-pressure homogenizer, and subjected to bath sterilization at 85°C for 25 minutes after bottling. After cooling, the product can be obtained without precipitation, and the product obtained has no precipitation.

Embodiment 3

[0031] (1) A total of 7Kg of raw tomato powder 802 and Fenkui are cleaned, first cut into pieces, and then put into a medium-sized cymbal crushing juicer with cymbal thorns inside for juice;

[0032] (2) Heat the obtained tomato juice at 80°C for 3 minutes, and then filter it with 150 mesh gauze;

[0033] (3) Add sugar, salt and vitamin C to the filtered tomato juice according to the formula. The mass percentage of sugar is 4.5%, the mass percentage of salt is 0.8%, the mass percentage of vitamin C is 0.03%, and the rest is tomato juice Then it is homogenized by a high-pressure homogenizer, and sterilized by Bath at 80°C for 20 minutes after bottling. After cooling, the product can be obtained without precipitation tomato juice.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com