Sugaring method of flavored preserved apples

A technology of candied apples, which is applied in the field of candied preserved apples, can solve problems such as poor color and single taste, and achieve the effects of improving production efficiency, increasing penetration rate, and solving single taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Divide the apples into two parts, one part is pickled, sliced, blanched, then rinsed with water for 24 hours, drained for later use; the other part is squeezed for juice, the pulp is centrifuged to remove pomace, and then filtered through gauze Get apple juice. Use sucrose to adjust the sugar content of apple juice to 12%, add 3.5% whey protein, and the pH is natural. After pre-sterilizing in a 90°C water bath, cool to 28°C, and add Streptococcus thermophilus (3.0×10 6 cfu / mL), Bifidobacterium longum (1.5×10 6 cfu / mL), Lactobacillus acidophilus (1.0×10 6 cfu / mL), fermented at 28°C for 70 hours and then stopped the fermentation to obtain fermented apple juice.

[0029] Adding sucrose to the fermented apple juice according to 55% by mass to prepare the confit solution.

[0030] The sugaring process conditions are as follows: put the apple slices in the sugaring liquid, and perform vacuum sugaring four times:

[0031] The vacuum degree of one sugar dip is -0.05MPa, the...

Embodiment 2

[0037] Divide the apples into two parts, one part is pickled, sliced, blanched, then rinsed with water for 24 hours, drained for later use; the other part is squeezed for juice, the pulp is centrifuged to remove pomace, and then filtered through gauze Get apple juice. Use sucrose to adjust the sugar content of the fruit juice to 8%, add 5% whey protein, natural pH, cool to 27°C after pre-sterilizing in a water bath at 90°C, and add Streptococcus thermophilus (2.5×10 6 cfu / mL), Bifidobacterium longum (1×10 6 cfu / mL), Lactobacillus acidophilus (2×10 6 cfu / mL), fermented at 27°C for 60 hours and then terminated the fermentation to obtain fermented apple juice.

[0038] Adding sucrose to the fermented apple juice according to 55% by mass to prepare the compote.

[0039] The sugaring process conditions are as follows: put the apple slices in the sugaring liquid, and perform vacuum sugaring four times:

[0040] The vacuum degree of one sugar dip is -0.06MPa, the temperature is 3...

Embodiment 3

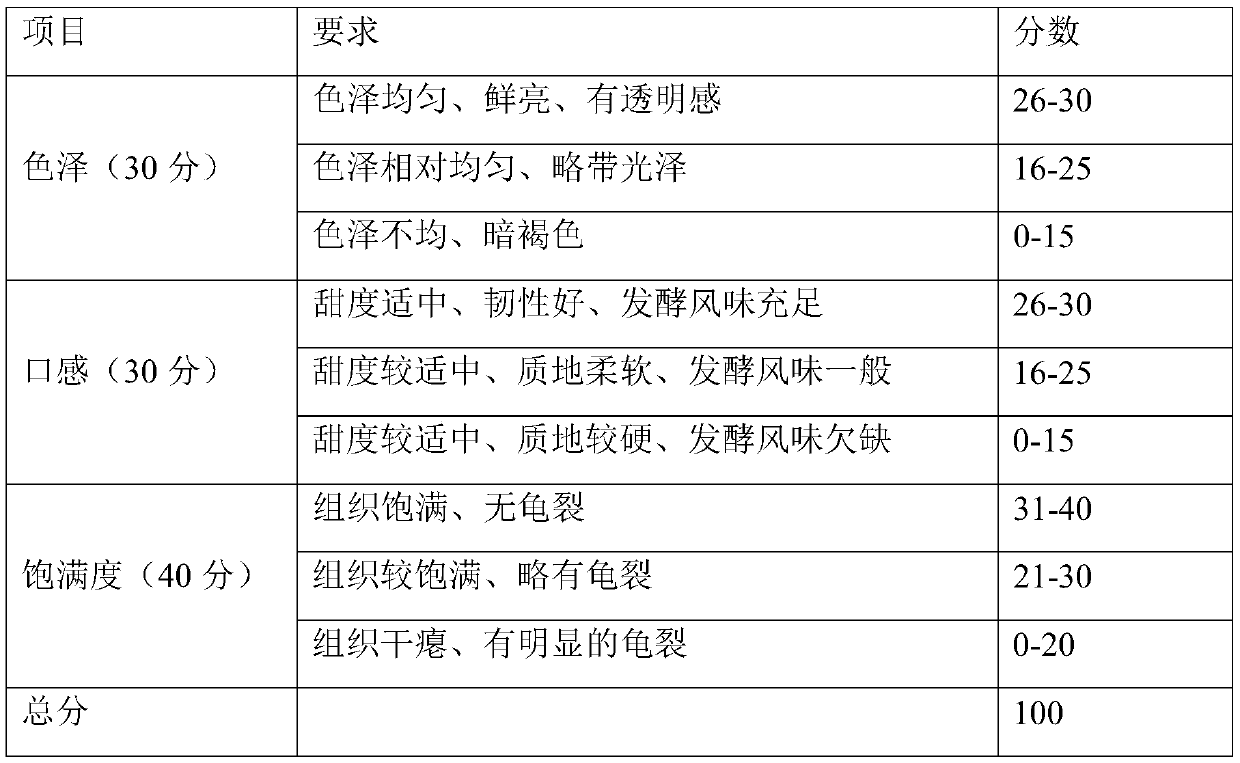

[0058] Embodiment 3, embodiment 1, 2, comparative example 1, 2 prepared flavor apple preserves and market common apple preserves are compared according to the result measured by SB / T 10085-92

[0059] Table 1: According to the SB / T 10085-92 industry standard for preserved apples, the sensory evaluation table for preserved apples was formulated

[0060]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com