All-in-one machine for straw crushing and returning to the field and residual film recycling

A technology of residual film recovery and straw crushing, applied in collectors, harvesters, crop processors, etc., can solve the problems of crop malnutrition, land quality decline, yield decline, etc., achieve efficient straw crushing and return to the field, save manpower and material resources , the effect of reducing the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

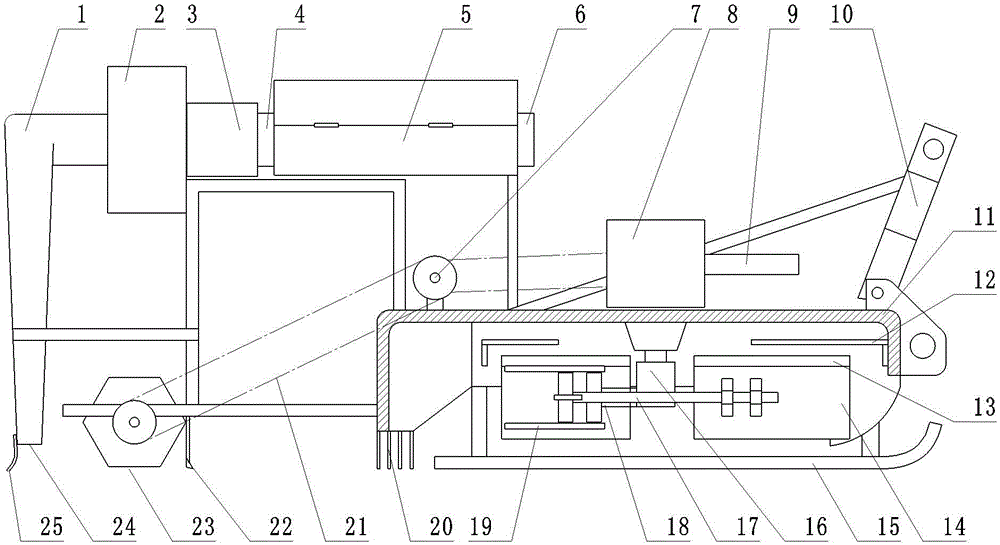

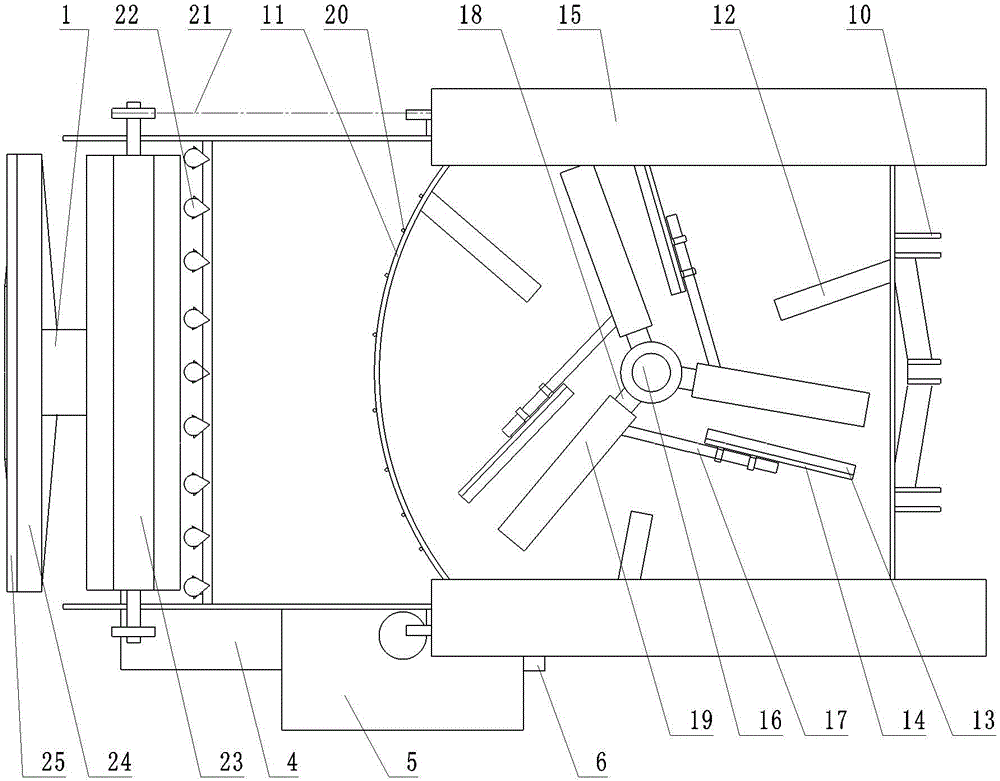

[0018] Example 1: refer to figure 1 — Figure 5 , figure 1 — Figure 5 It is a structural schematic diagram of Embodiment 1 of the present invention, including a frame 11, a traction frame 10, a fan 2 and a power 3, the fan 2 is arranged on the rear side of the frame 11, the power 3 is connected to the fan 2, and the air inlet of the fan 2 is provided There is a residual film suction pipe 1, the lower end of the residual film suction pipe 1 is provided with a flat film suction port 24, a gearbox 8 is provided at the front end of the frame 11, and a traction frame 10 is provided at the front end of the frame 11 for The traction is on the tractor, the bottom end of the frame 11 is provided with a slide plate 15, and the front end of the slide plate 15 is tilted, which can facilitate the dragging of the tractor. The frame 11 is provided with a transmission shaft 9, which is connected to the power of the tractor. The other end of the transmission shaft 9 is provided with a ge...

Embodiment 2

[0019] Example 2: refer to Figure 6 , Figure 6 It is a schematic structural view of Embodiment 2 of the present invention. Compared with Embodiment 1, the difference between Embodiment 2 and Embodiment 1 is that the shape of the wrapping roller 23 in Embodiment 2 is circular, and a similar Effect.

Embodiment 3

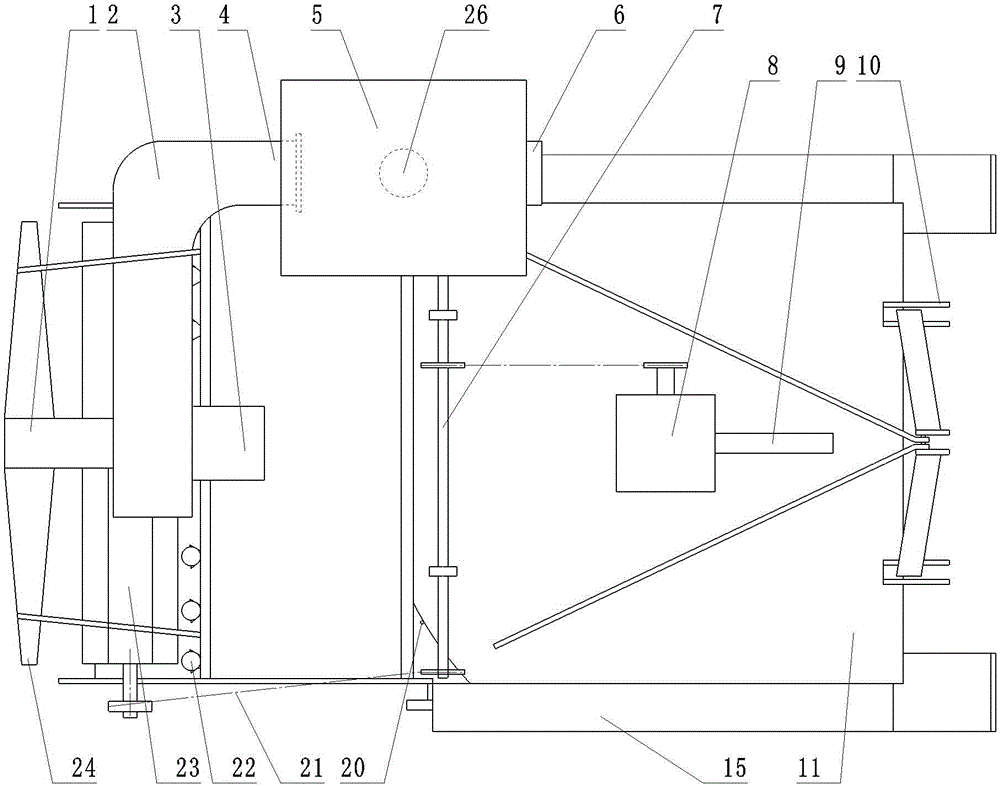

[0020] Example 3: refer to Figure 7 , Figure 7 It is a structural schematic diagram of embodiment 3 of the present invention. Compared with embodiment 1, the difference between embodiment 3 and embodiment 1 is that two film turning knives, film wrapping rollers, and suction film are provided in embodiment 3. mouth, can further improve the recovery rate of plastic film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com