scroll compressor

A scroll compressor and scroll technology, applied in the direction of rotary piston machines, rotary piston pumps, mechanical equipment, etc., can solve problems such as poor lubrication, extreme decrease in viscosity of lubricating oil, stable support of rotating shaft bearing damage, etc. , to achieve the effect of low friction characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] A more detailed description of the manner of carrying out the present invention will be given below with reference to preferred embodiments shown in the accompanying drawings. It should be noted that the present invention is not limited to this embodiment.

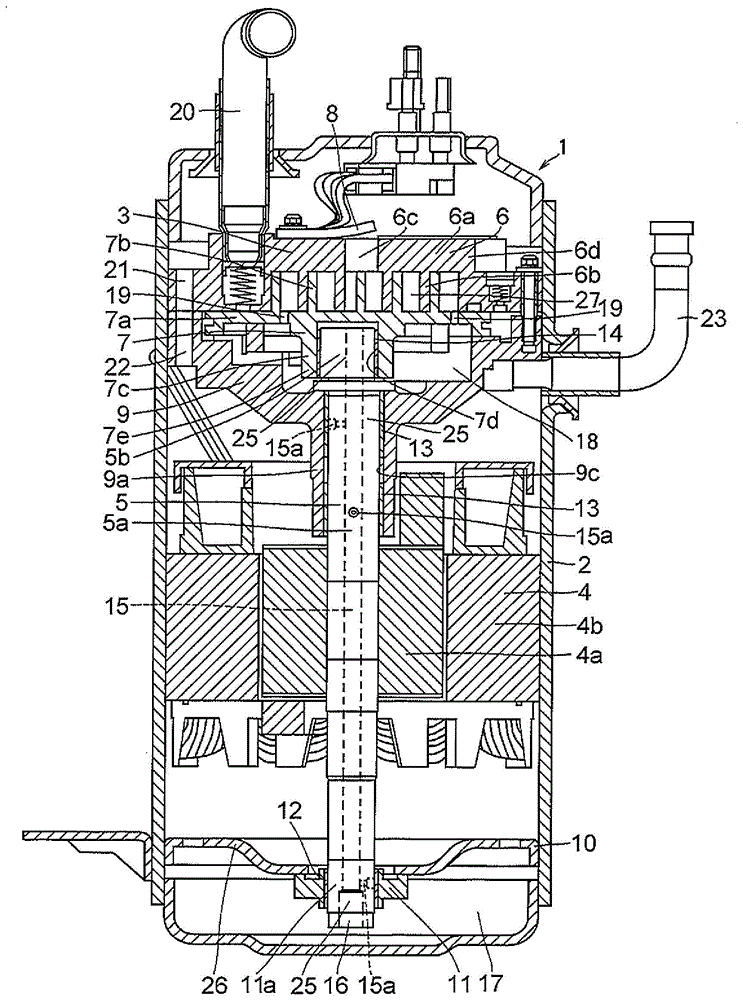

[0029] exist figure 1Among them, a scroll compressor 1 has a tubular closed container 2 with both ends closed, and in the closed container 2, a scroll compression mechanism part 3 is arranged in the upper part inside the closed container 2, and a motor 4 is arranged in the lower part thereof . These two components are interlocked and coupled to each other by means of the output rotary shaft 5 . The motor 4 is composed of a rotor 4 a and a stator 4 b, and the rotor 4 a is fixed to the output rotary shaft 5 and the stator 4 b is fixed to the closed container 2 . The scroll compression mechanism portion 3 has a fixed scroll 6 and an orbiting scroll 7 meshing with each other. The fixed scroll 6 has an end plate 6a a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com