Tool special for controlling peeling of cable

A special tool and cable control technology, which is applied in the direction of dismantling/armoring cable equipment, etc., can solve problems such as cable knife slippage or uneven depth control, failure to meet safety production, cable core insulation damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

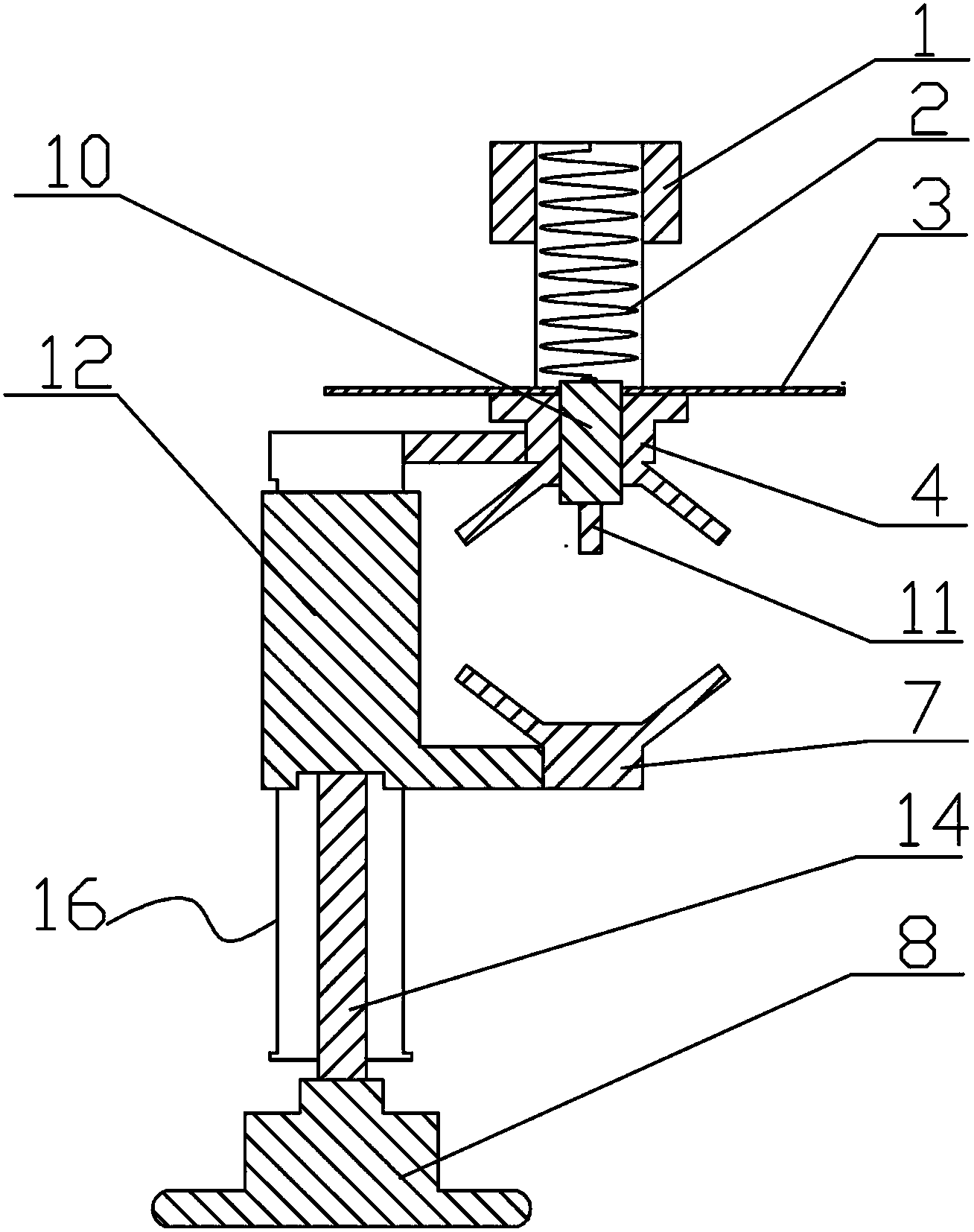

[0022] Embodiment 1: as figure 1 , figure 2 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 As shown, the present invention includes a sleeve 13, and a first sliding groove 16 is provided on the side wall of the sleeve 13, and a movable slider structure is arranged in the first sliding groove 16, and the movable slider structure includes a second slider 12. Screw 14, the end of the second slider 12 is provided with an adjusting screw mounting hole, the head of the adjusting screw 14 is rotationally connected with the adjusting screw mounting hole, and the bottom of the sleeve 13 is provided with a threaded hole corresponding to the adjusting screw 14 , the adjusting screw 14 passes through the threaded hole at the bottom of the sleeve 13 , and the tail of the adjusting screw 14 is provided with an adjusting knob 8 . The second slider 12 is fixedly provided with a mobile cable clamp 7, and a corresponding fixed cable clamp 4 is arranged above the mobile cable...

Embodiment 2

[0023] Embodiment 2: as image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9As shown, the present invention includes a sleeve 13, and a first sliding groove 16 is provided on the side wall of the sleeve 13, and a movable slider structure is arranged in the first sliding groove 16, and the movable slider structure includes a second slider 12. A second spring 15 is arranged on the second slider 12 , one end of the second spring 15 is fixedly connected to the second slider 12 , and the other end of the second spring 15 is fixedly connected to the bottom of the sleeve 13 . The second slider 12 is fixedly provided with a mobile cable clamp 7, and a corresponding fixed cable clamp 4 is arranged above the mobile cable clamp 7. The fixed cable clamp 4 is fixedly connected with the upper end of the sleeve 13, and the fixed cable clamp 4 The upper side is provided with a hollow screw 9, one end of the hollow screw 9 is fixedly connected with the fixed c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com