Anti-fake and anti-channel conflict label and preparing method thereof

A technology to prevent smuggling and labeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

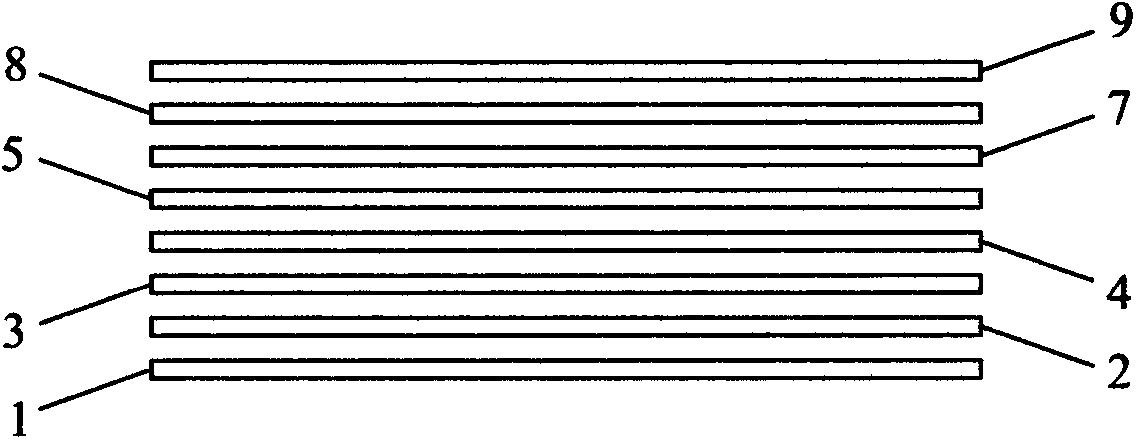

[0034] see figure 1 , as shown in the figure, an anti-counterfeiting and anti-smuggling label includes a backing paper layer 1, a printing layer 4 covering the backing paper layer 1, and a bottom-to-bottom paper layer is further included between the printing layer 4 and the backing paper layer 1 The isolation layer 2 and the first adhesive layer 3, the isolation layer 2 is located above the bottom paper layer 1, the first adhesive layer 3 is located below the printing layer 4, and also includes a two-dimensional code printing layer 5 printed on the printing layer 4, A moisture-sensitive material layer 8 is compounded on the top of the two-dimensional code printing layer 5 , a second adhesive layer 7 is formed between the two-dimensional code printing layer 5 and the moisture-sensitive material layer 8 , and a surface printing layer 9 is printed on the top of the moisture-sensitive material layer 8 . A two-dimensional code printing layer 5 is completely printed on the printing ...

Embodiment 2

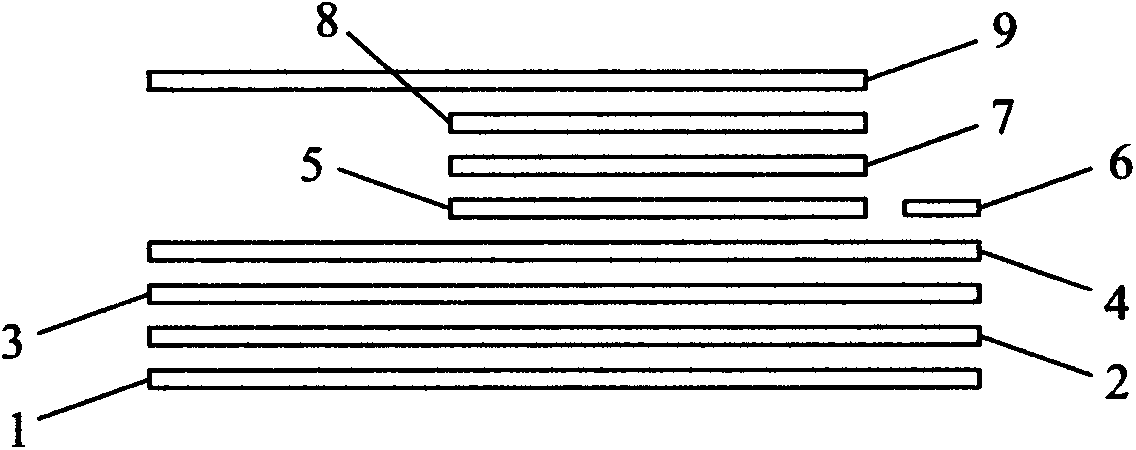

[0036] see figure 2 , as shown in the figure, an anti-counterfeiting and anti-smuggling label includes a backing paper layer 1, a printing layer 4 covering the backing paper layer 1, and a bottom-to-bottom paper layer is further included between the printing layer 4 and the backing paper layer 1 The isolation layer 2 and the first adhesive layer 3, the isolation layer 2 is located above the bottom paper layer 1, the first adhesive layer 3 is located below the printing layer 4, and also includes a two-dimensional code printing layer 5 printed on the printing layer 4, A moisture-sensitive material layer 8 is compounded on the top of the two-dimensional code printing layer 5 , a second adhesive layer 7 is formed between the two-dimensional code printing layer 5 and the moisture-sensitive material layer 8 , and a surface printing layer 9 is printed on the top of the moisture-sensitive material layer 8 . An alignment color mark layer 6 is also printed on the printing layer 4 , and...

Embodiment 3

[0038] see image 3 , as shown in the figure, an anti-counterfeiting and anti-smuggling label includes a backing paper layer 1, a printing layer 4 covering the backing paper layer 1, and a bottom-to-bottom paper layer is further included between the printing layer 4 and the backing paper layer 1 The isolation layer 2 and the first adhesive layer 3, the isolation layer 2 is located above the bottom paper layer 1, the first adhesive layer 3 is located below the printing layer 4, and also includes a two-dimensional code printing layer 5 printed on the printing layer 4, A moisture-sensitive material layer 8 is compounded on the top of the two-dimensional code printing layer 5 , a second adhesive layer 7 is formed between the two-dimensional code printing layer 5 and the moisture-sensitive material layer 8 , and a surface printing layer 9 is printed on the top of the moisture-sensitive material layer 8 . An alignment color mark layer 6 is also printed on the printing layer 4 , and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com