Strip surface defect recognition method based on multi-manifold learning

A defect recognition and multi-manifold technology, applied in character and pattern recognition, instruments, computer components, etc., can solve problems such as poor classification effect and insignificant application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

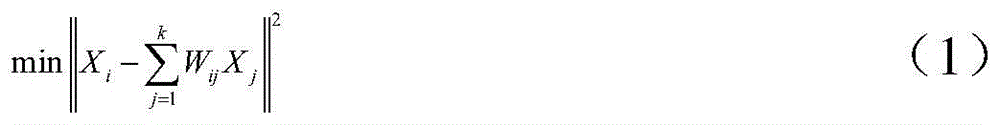

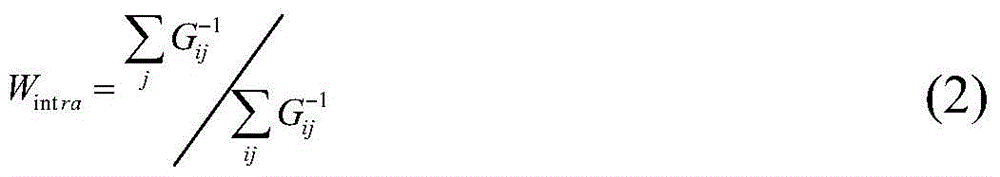

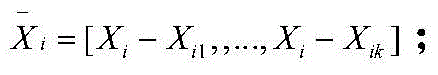

Method used

Image

Examples

Embodiment 1

[0050] A strip steel surface defect recognition method based on multi-manifold learning, the specific steps are:

[0051] (1) Perform grayscale processing, smoothing processing, normalization processing and vectorization on the original collected strip surface defect image in sequence to obtain a pair of vector data points X after preprocessing of the strip surface defect image i , the vector data X of all strip surface defect images preprocessed i Form matrix data X. In this embodiment, 4 types of strip steel surface defect images are collected, and the defect categories of the 4 types of strip steel surface defect images refer to weld seams, edge serrations, inclusions and head lines; each type of data has a total of 40 pieces, and each piece has a size of 100* 100, a pair of vector data points X after preprocessing of the strip surface defect image i is 10000 dimensions, all strip surface defect image preprocessed vector data X i Form the matrix data X of 160*10000.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com