Thermodynamic calculation method for continuous spiral baffle plate shell-and-tube heat exchanger

A technology of shell-and-tube heat exchanger and continuous spiral, which is applied in the direction of calculation, instrumentation, and special data processing applications, etc., and can solve the design of continuous spiral baffle shell-and-tube heat exchanger that has never been seen, and has no commercial software. Difficulties in manufacturing and promoting applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

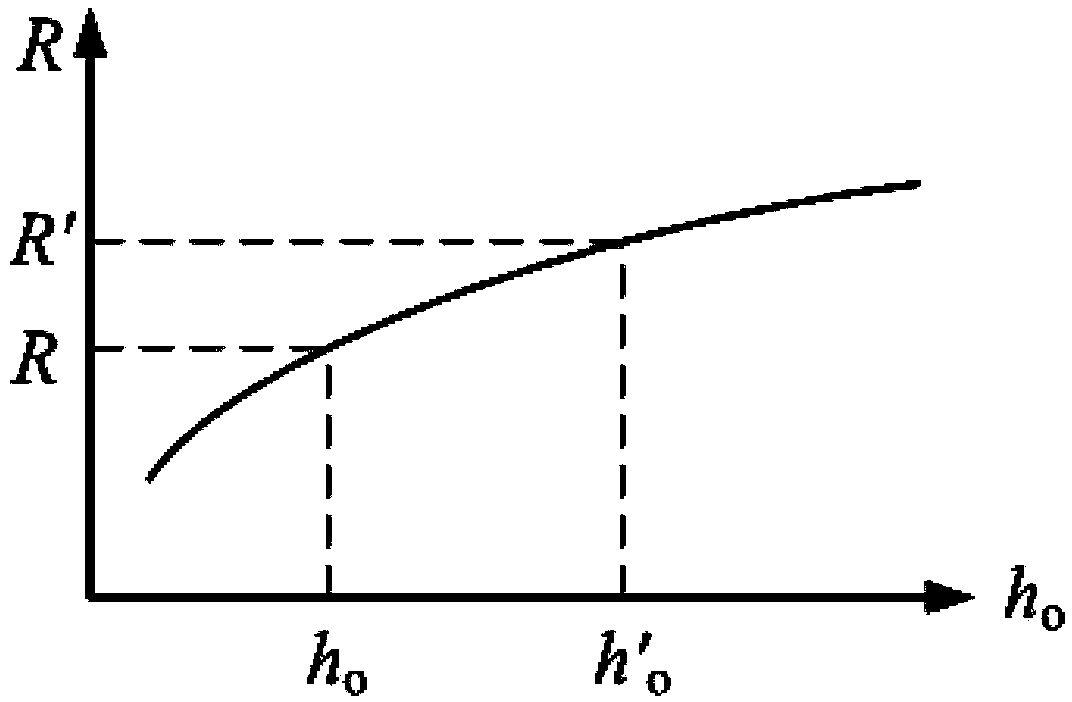

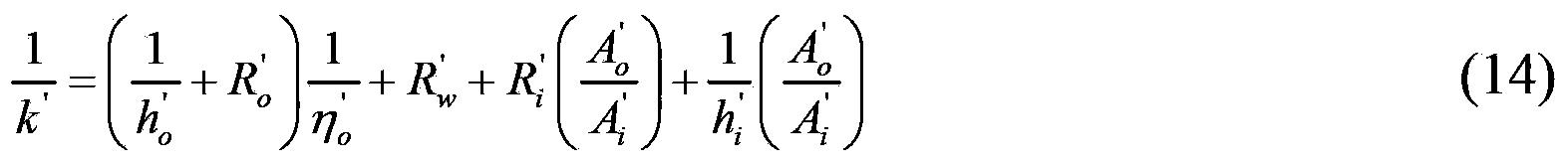

[0045] The invention provides a single-shell-pass multi-tube-pass continuous spiral baffle using a single-phase medium and a light pipe (or other tube types such as corrugated tubes, corrugated tubes, or low-rib tubes that can be used in the form of baffles) The shell-side thermodynamic calculation method of the shell-and-tube heat exchanger simplifies the design process of the continuous spiral baffle shell-and-tube heat exchanger into a single-bow baffle shell-and-tube heat exchanger design and a continuous spiral heat exchanger based on the maximum flow rate ratio. Baffled shell and tube heat exchangers are calculated in two parts. Specifically include the following steps:

[0046] 1) Determine the thermal load based on the known thermal parameters (including mass flow on the shell side of the heat exchanger and mass flow on the tube side, etc.). According to the qualitative temperature of the shell side and the qualitative temperature of the tube side, find or calculate t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com