Optical fiber reinforcement meter

A steel bar meter and fiber optic technology, applied in the field of measurement, can solve the problems of low sensitivity, high insulation requirements, and poor durability of differential resistance steel bar meters, and achieve strong anti-interference ability, high sensitivity, and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below with reference to the accompanying drawings and examples.

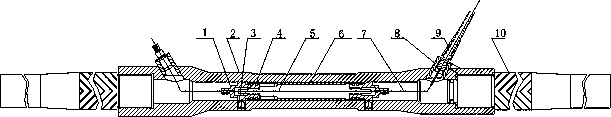

[0017] like figure 1 As shown, an embodiment of the present invention has a fiber grating sensitive component 1 and a sensing sleeve 2 . The fiber grating sensitive part 1 is fixed on the sensing sleeve 2 through the tightening part 3 or welding. The sensing sleeve 2 is made of high-strength material, and different shapes and sizes can be designed according to different measurement requirements. The two ends of the sensing sleeve 2 are connected with steel connecting rods 10, and the connecting rods 10 and the sensing sleeve 2 are connected by thread or welding.

[0018] The fiber grating sensitive part 1 comprises an elastomer base 4 , a fiber grating 5 and a protective housing 6 . The optical fibers at both ends of the fiber grating 5 are fixed in the elastomer base 4 by bonding or welding, and are packaged in the protective casing 6 for protec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com