Stepless speed changing box of large-power tractor

A continuously variable transmission and tractor technology, which is applied in the field of tractors, can solve the problems of difficulty in guaranteeing the reliability of the transmission, high requirements on the cleanliness of the hydraulic system, and high performance requirements on hydraulic components, so as to achieve reduced auxiliary working time, excellent economy, and The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

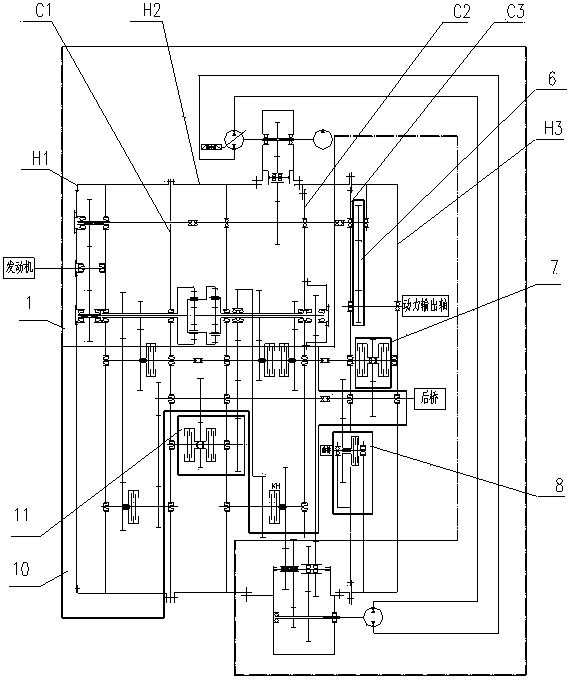

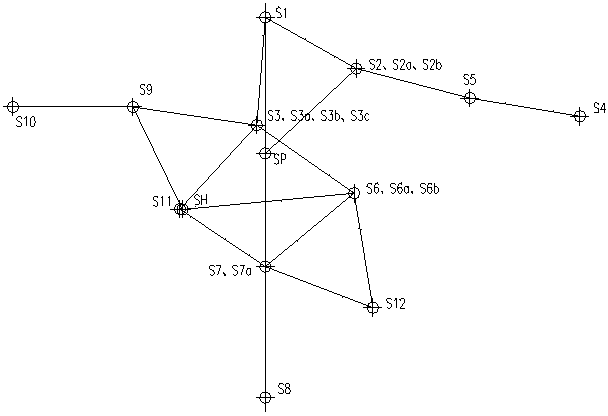

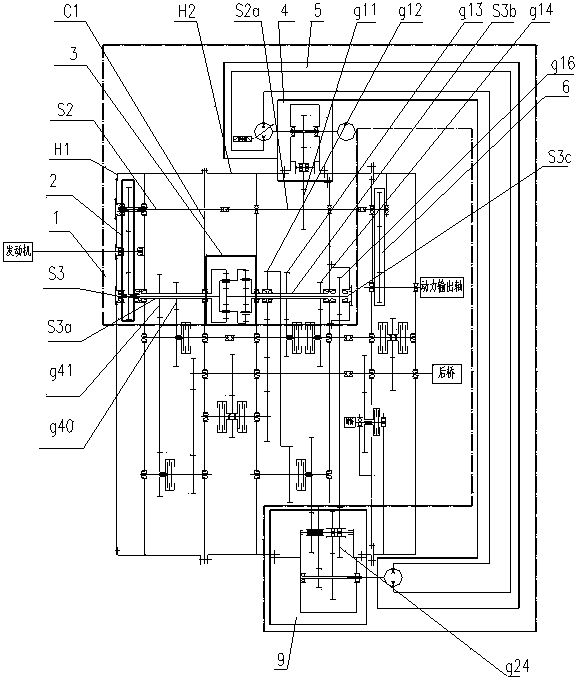

[0031] The present invention will be further described below in conjunction with embodiment. Such as figure 1 As shown, the high-power tractor CVT includes: gearbox front box H1, middle box H2, rear box H3, first clapboard C1, second clapboard C2, third clapboard C3, hydraulic machinery Dual-flow transmission 1 and fixed-shaft variable-speed transmission 10 , forward transmission 7 and reverse transmission 11 , four-wheel drive transmission 8 , power take-off 6 . The front box H1, the middle box H2, and the rear box H3 of the gearbox are arranged in sequence. The front box H1 and the middle box H2 of the gearbox are connected by bolts through the first partition C1, and the rear box H3 and the middle box H2 They are connected with bolts, and the second partition C2 and the third partition C3 are respectively installed with bolts in the middle box H2 and the rear box H3, thereby forming six component installation cavities in the gearbox box for installing various transmissio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com