Cooling system

A cooling system and fan technology, which is applied to engine cooling, coolant flow control, fluid pressure actuation system components, etc. Working time, avoiding overheating and undercooling, the effect of improving the efficiency ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

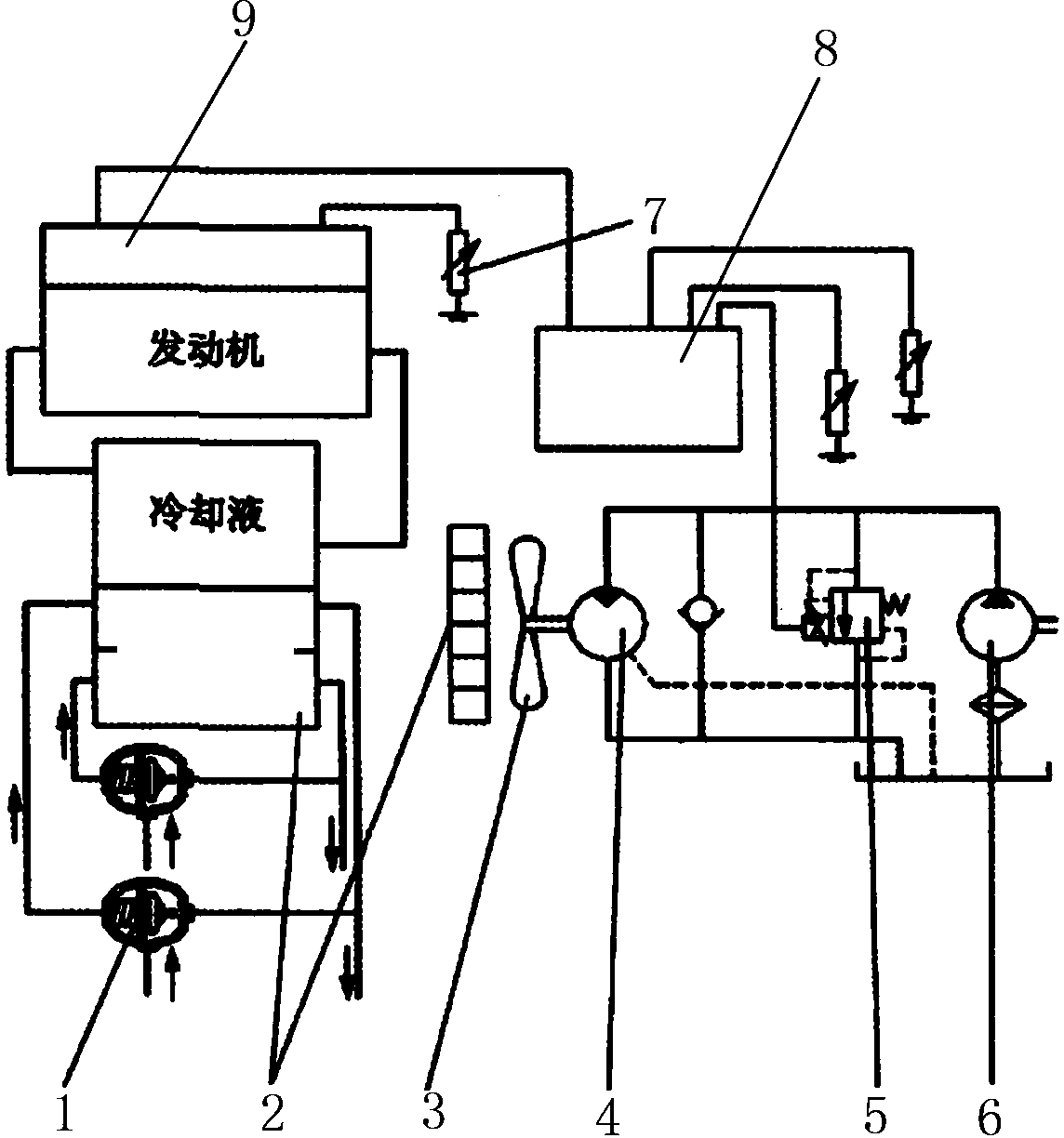

[0007] As shown in the figure, the cooling system of the present invention includes a fan 3, the fan 3 is connected with the quantitative motor 4, the electric proportional overflow valve 5, the quantitative pump 6, and the oil tank in sequence, wherein the electric proportional overflow valve 5 is also connected with the control The radiator 8 and the temperature sensor 7 are connected, and the temperature sensor 7 is connected with the engine ECU9 through the CAN bus. In addition, the front end of the fan 3 is also equipped with a radiator 2, and the radiator 2 is connected with the hydraulic oil and the torque converter oil through the temperature control valve 1.

[0008] The temperature sensor 7 is connected with the controller 8 through a cable, and the temperature signal of the engine coolant is provided by the engine ECU 9 through the CAN bus. Quantitative pump 6 is connected with oil tank through filter, and the output shaft of quantitative motor 4 is connected with co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com