Aloft work platform

A kind of high-altitude work platform and platform technology, which is applied in the direction of house structure support, house structure support, house structure support scaffolding, etc., and can solve problems such as troublesome operation, time-consuming, and heavy equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

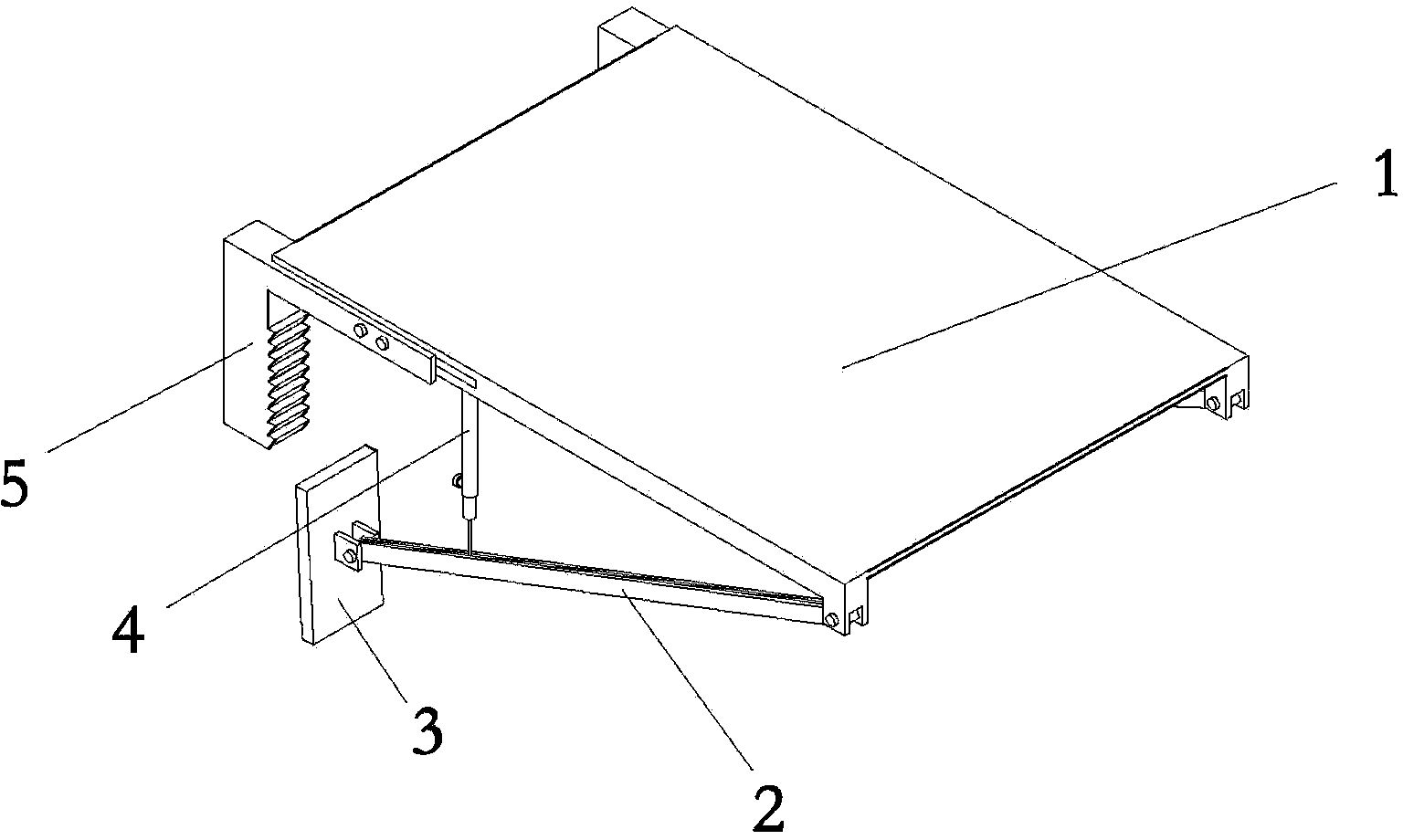

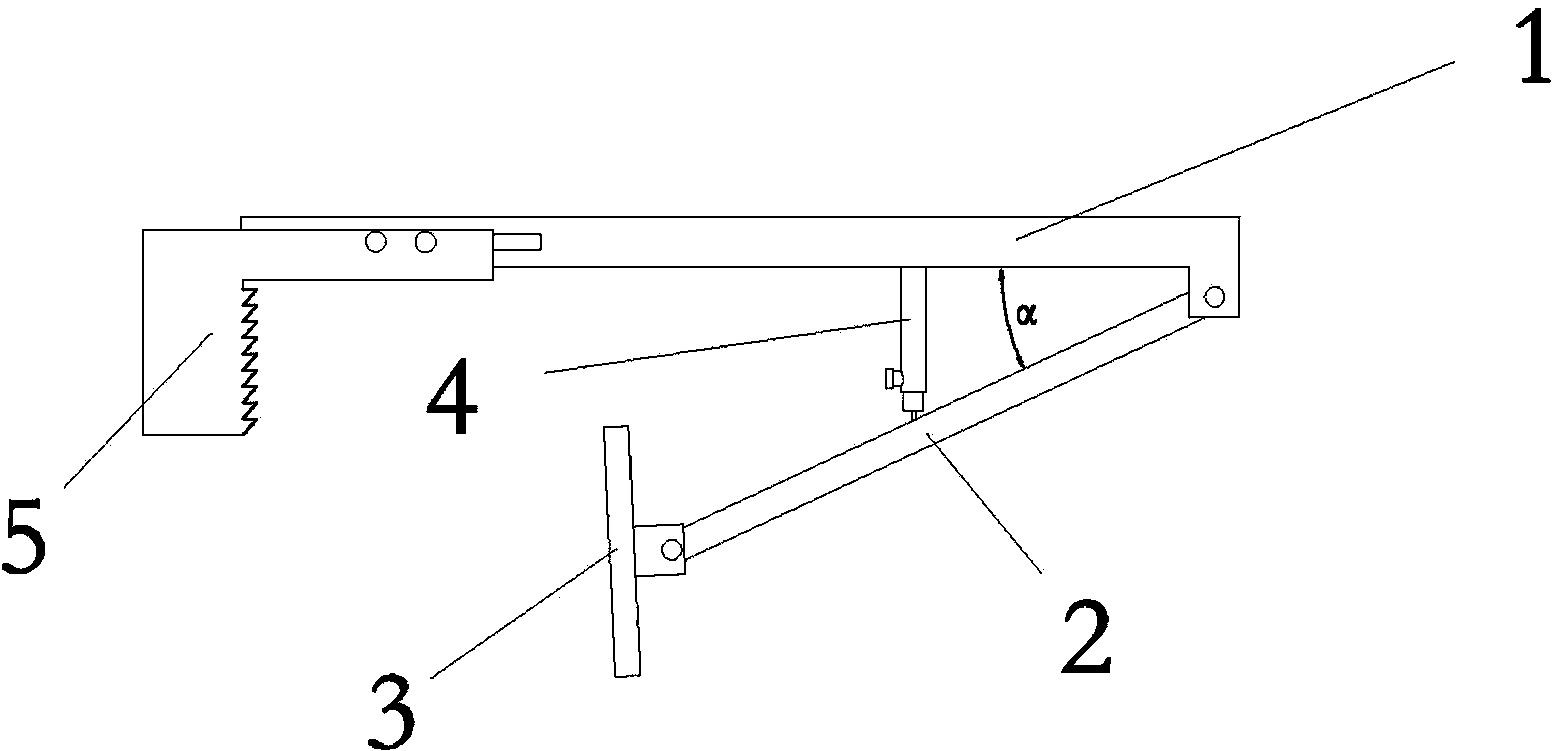

[0032] The α angle of the present embodiment is adjustable, and the structure is as follows:

[0033] The position of the fixed rod 4 is fixed, the length is adjustable, and it has a locking device capable of locking the adjusted length of the fixed rod 4; specifically: one end of the support leg 2 is pinned to the end of the table top 1, and the other end Pinned to the static friction disc 3; one end of the fixed rod 4 is fixedly connected to the bottom of the table top 1, and the other end is provided with a sliding head, and the sliding head is embedded in the chute of the supporting leg 4; Rod 4 is a set of sleeve pipes, and a knob for fixing the length of the sleeve pipes is arranged on the rod; the sliding head is spherical or rugby ball-shaped;

[0034] The lock 5 has a saw-toothed friction surface, the axial section is L-shaped with a 90° clockwise rotation, and the lock 5 can slide axially relative to the table top and lock after sliding.

Embodiment 2

[0036] The α angle of the present embodiment is adjustable, and the structure is as follows:

[0037] The length of the fixed rod 4 is fixed, the position is adjustable, and there is a locking device capable of locking the adjusted position of the fixed rod 4;

[0038] Specifically: one end of the support leg 2 is pinned to the end of the table top 1, and the other end is pinned to the static friction disc 3; both ends of the fixed rod 4 are provided with sliding heads, and a sliding head is embedded in the In the chute at the bottom of the table top 1, another sliding head is embedded in the chute of the support leg 2; the chute at the bottom of the table 1 and the chute of the support leg 2 are provided A loose limit block, the limit block is slidably connected to the chute; the sliding head is spherical or rugby ball-shaped;

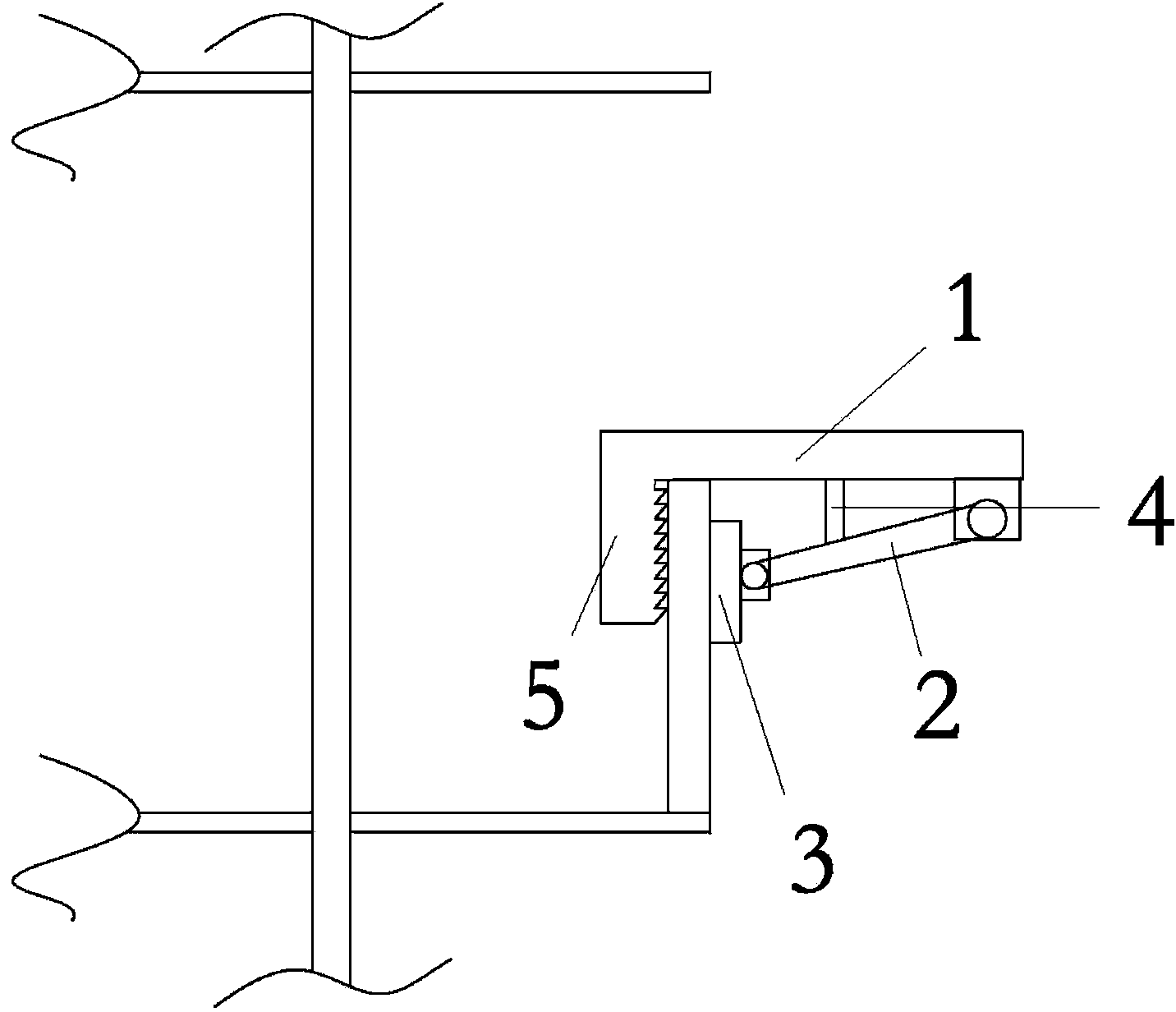

[0039] The lock 5 has a saw-toothed friction surface, the axial section is L-shaped with a 90° clockwise rotation, and the lock 5 can slide axially ...

Embodiment 3

[0041] The α angle of the present embodiment is constant, and the structure is as follows:

[0042] The positions among the table top 1 , the supporting legs 2 , the static friction disc 3 , the fixing rod 4 and the lock catch 5 are relatively fixed. Buckle 5 can be iron cable or hoop.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com