Wet joint construction method of T-shaped beam bridge floor system

A construction method and technology of wet joints, applied in the direction of bridges, bridge construction, bridge parts, etc., can solve the problems of low formwork reuse rate, difficulty in formwork removal, and easy damage to formwork support devices, so as to improve construction efficiency and repeat The effect of high utilization rate and convenience for next use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

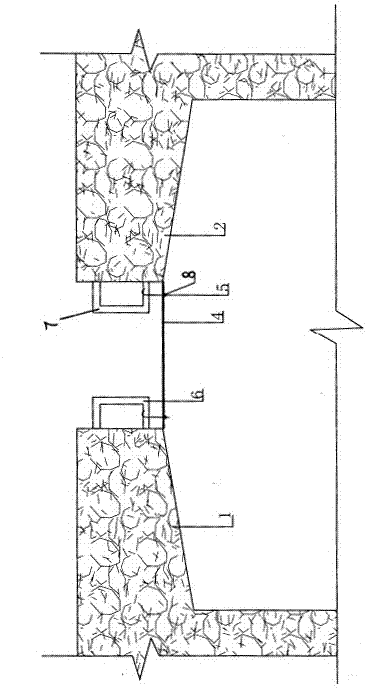

[0017] A T-shaped girder deck system wet joint formwork support device, comprising a left T-shaped beam 1 and a right T-shaped beam 2, a wet joint is arranged between the left T-shaped beam 1 and the right T-shaped beam 2, and the left T-shaped beam 2 is provided with a wet joint. The right end 6 of the embedded steel bar of the shaped beam 1 is set in the wet joint, the left end 7 of the embedded steel bar of the right T-shaped beam 2 is set in the wet joint, and two rows of reserved steel bars are arranged on the thin steel formwork 4 A thread is provided at the tail end of the hook 5, and the tail end of the hook 5 passes through the reserved hole and is screwed together with the nut 8, and the head of the hook 5 passing through the reserved hole 3 in the left row The upper hook is hooked on the right end 6 of the embedded steel bar of the left T-shaped beam 1, and the head hook of the suspension hook 5 passing through the reserved hole in the right row is hooked on the pre-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com