Scrapping device for ground scarification machine, ground scarifier and method for controlling said scraper device

A scraping device and plowing technology, applied in roads, road repairs, roads, etc., can solve problems such as expensive and complex structure of scraping devices, and achieve high functional reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

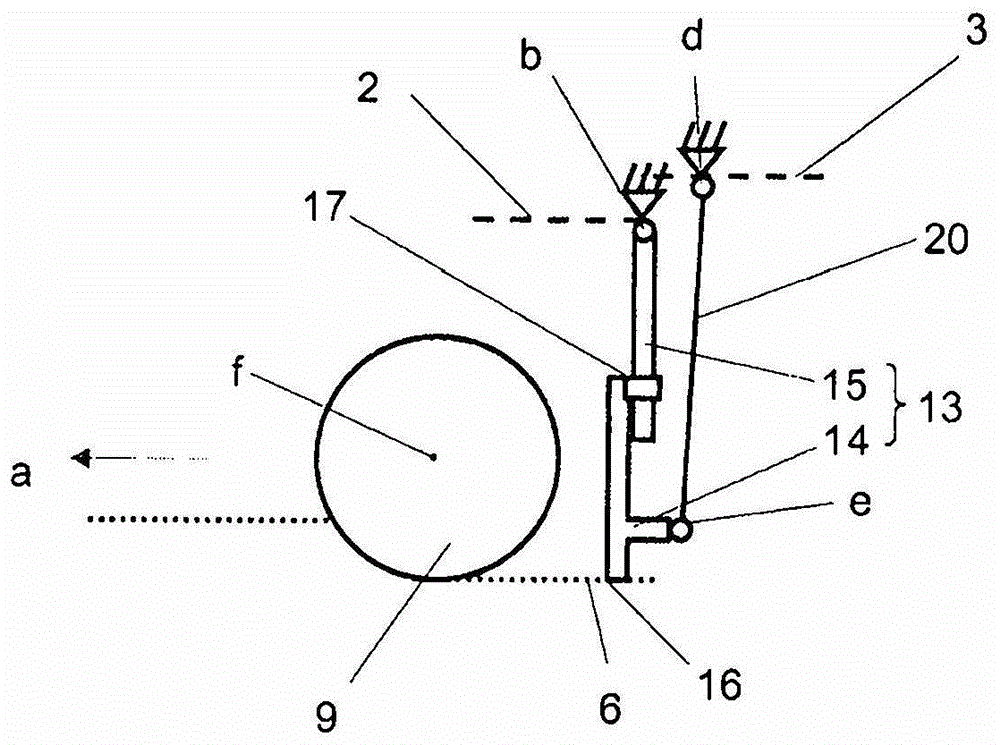

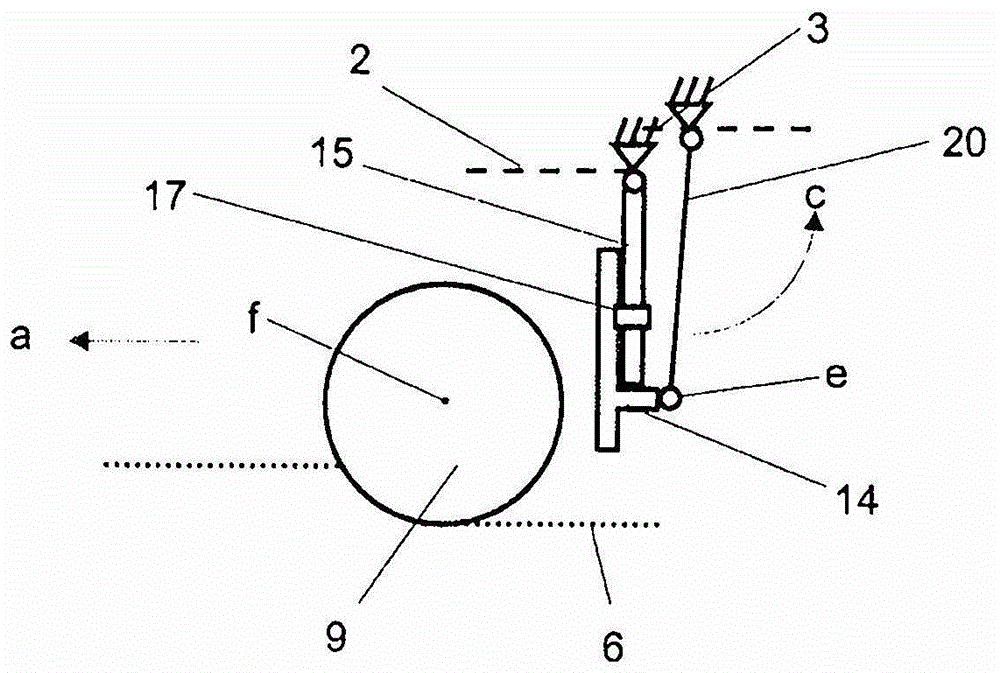

[0039] Structurally identical components are identified in the figures with the same reference numerals, and for the sake of clarity, parts that are repeated in the figures are not necessarily shown again in each figure.

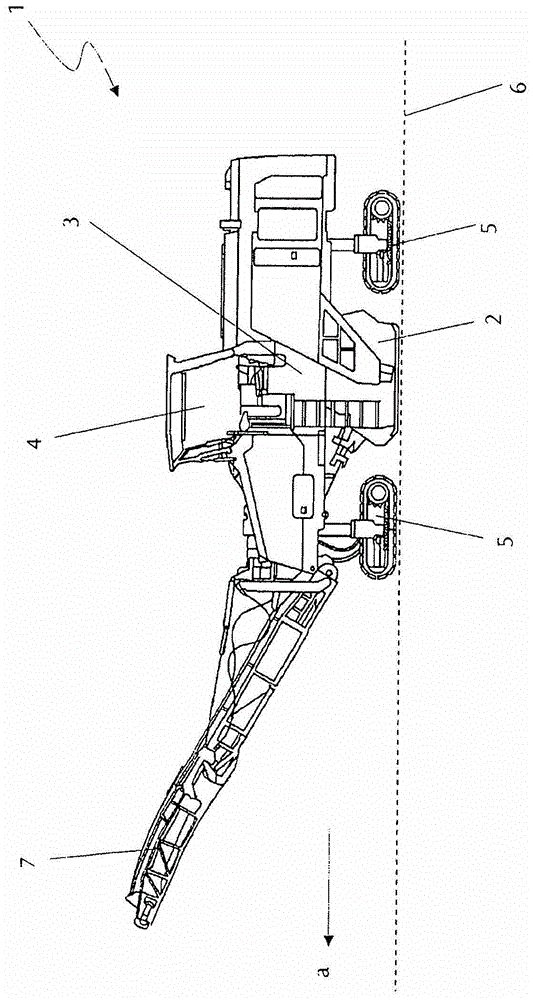

[0040] figure 1 A side view of a ground scarifier 1 , in particular a road scarifier, is shown. The working direction (forward direction) is indicated by arrow a. The main elements of the construction machine 1 are: a loosening roller box 2, a frame 3 of the driver's platform 4 and a crawler-type traveling mechanism 5 supported on the frame 3 by lifting columns. The ground scarifying machine 1 also includes a drive motor, not shown in detail, which, in addition to the propulsion power in the working direction a, is in particular also a scarifying roller (in figure 1 not drawn in detail) to provide driving energy. The scarifying rollers are arranged inside the scarifying roller box 2 and have an axis of rotation extending horizontally and transversely to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com