Quenching device with conveying function

A quenching device and function technology, applied in the field of casting processing equipment, can solve the problems of difficulty in ensuring the quenching quality of quenched castings, quenching uniformity, uncontrollable quenching speed, quenching depth, and increased workload of workers, etc. Simple, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the accompanying drawings.

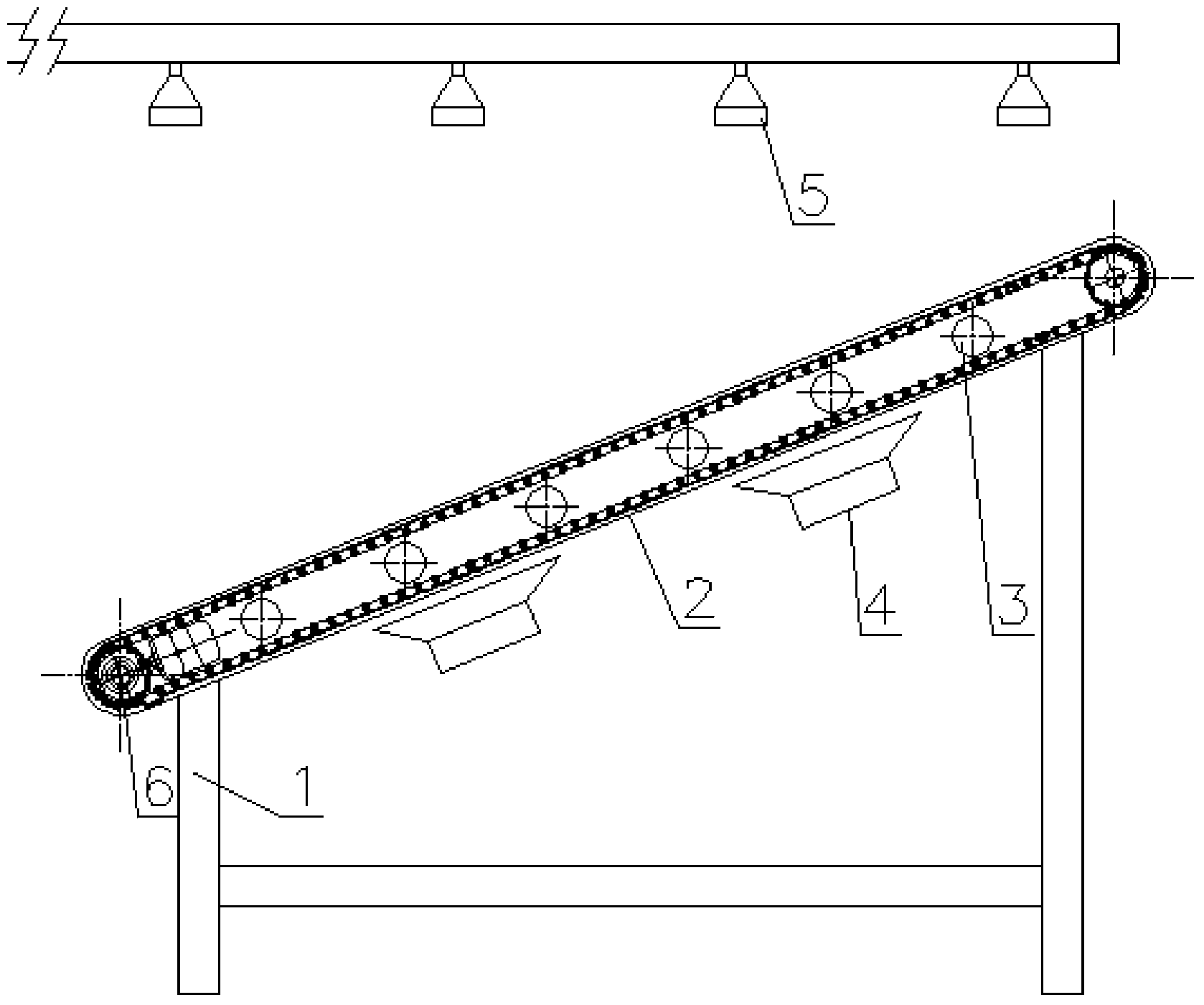

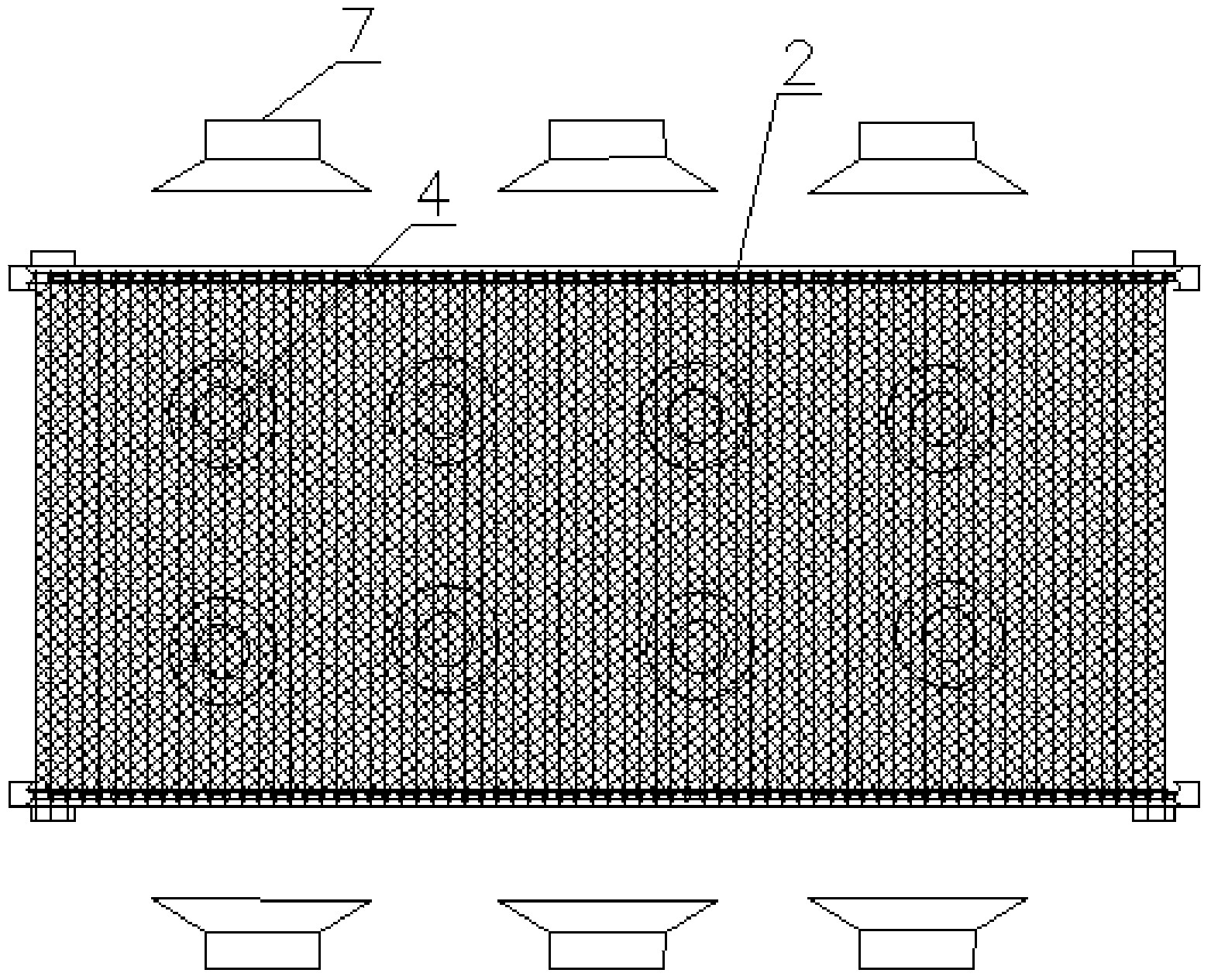

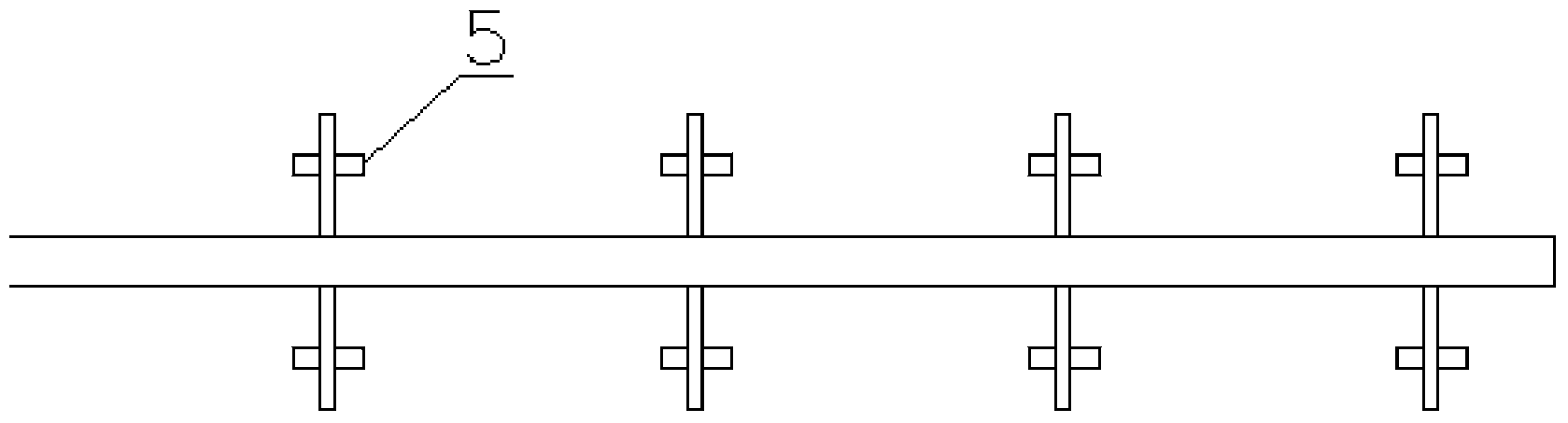

[0026] As a preferred embodiment of the present invention, please refer to figure 1 -3, the conveying mechanism 2 is used to place the casting and make it move. It is preferably set as a mesh conveyor chain, and it is internally provided with some idlers 3 that roll along with the operation of the mesh conveyor chain. The advantage of setting the idler 3 is that it can improve The support strength of the mesh conveyor chain can increase the number of castings carried at the same time, thereby improving the processing efficiency. At the same time, the mesh conveyor chain is powered by a gearbox 6 driven by an asynchronous motor.

[0027] A quenching mechanism for quenching the castings is arranged on the mesh conveyor chain along the running direction of the castings. The quenching mechanism includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com