Method for separating alkanes and olefin in etherification C4 fractions

A technology for C4 fractionation and middle carbon tetraalkanes, which is applied in the direction of chemical change purification/separation, organic chemistry, etc., can solve the problems of easy decomposition of solvents, high cost, large investment, etc., and achieve the effect of wide application and complete separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

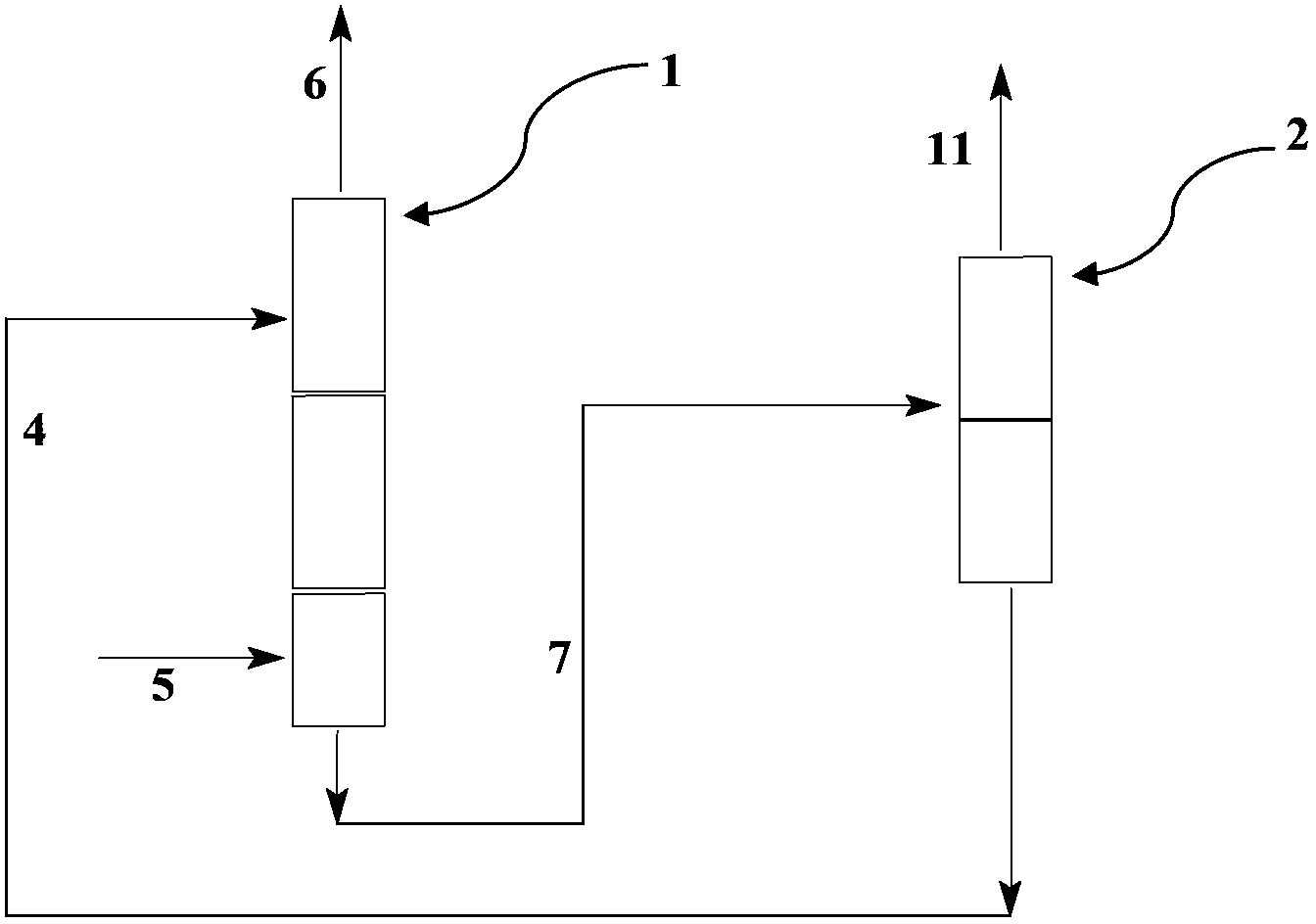

Image

Examples

Embodiment 1

[0023] The acetic acid raw material is glacial acetic acid with a purity greater than 99.5%. Reactor 1 is composed of 44.19% isobutane, 13.23% n-butane, 13.76% 1-butene, 16.55% t-2-butene, 0.1% isobutene, c -2-butene 11.75% ether after C 4 fraction.

[0024] The catalyst is macroporous strongly acidic styrene series cationic resin, the brand is NKC-9, and 50 grams of the catalyst is packaged and loaded into the reactor as a whole.

[0025] Step i: The temperature at the top of the reactor is 50°C, the temperature at the bottom of the reactor is 180°C, and the pressure is 1.0MPa. After acetic acid and ether, C 4 The molar ratio of carbon tetraolefins in the distillate is 1.1, after the ether C 4 Distillate weight space velocity 3h -1 . Acetic acid enters from the top of reactor 1 with a metering pump, and after ether, C 4 The fraction enters from the bottom of Reactor 1 through a liquid mass flow meter.

[0026] Step ii: The temperature at the top of the reactor is 30°C, ...

Embodiment 2

[0029] The acetic acid raw material is glacial acetic acid with a purity greater than 99.5%. Reactor 1 is composed of 0.25% isobutane, 20.45% n-butane, 5.11% 1-butene, 43.72% t-2-butene, 0.12% isobutene, c -2-butene 30.17% ether after C 4 fraction.

[0030] The catalyst is macroporous strongly acidic styrene series cationic resin, the brand is NKC-9, and 50 grams of the catalyst is packaged and loaded into the reactor as a whole.

[0031] Step i: The temperature at the top of the reactor is 50°C, the temperature at the bottom of the reactor is 150°C, and the pressure is 1.0MPa. After acetic acid and ether, C 4 The molar ratio of carbon tetraolefins in the distillate is 1.1, after the ether C 4 Distillate weight space velocity 2h -1 . Acetic acid enters from the top of reactor 1 with a metering pump, and after ether, C 4 The fraction enters from the bottom of Reactor 1 through a liquid mass flow meter.

[0032] Step ii: The temperature at the top of the reactor is 30°C, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com