Child seat installation structure

A technology for child seats and mounting parts, applied in child seats, vehicle seats, vehicle parts, etc., can solve the problems of seat recessed appearance and complex structure of skin parts, and achieve beautified appearance, simple structure, and easy connection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

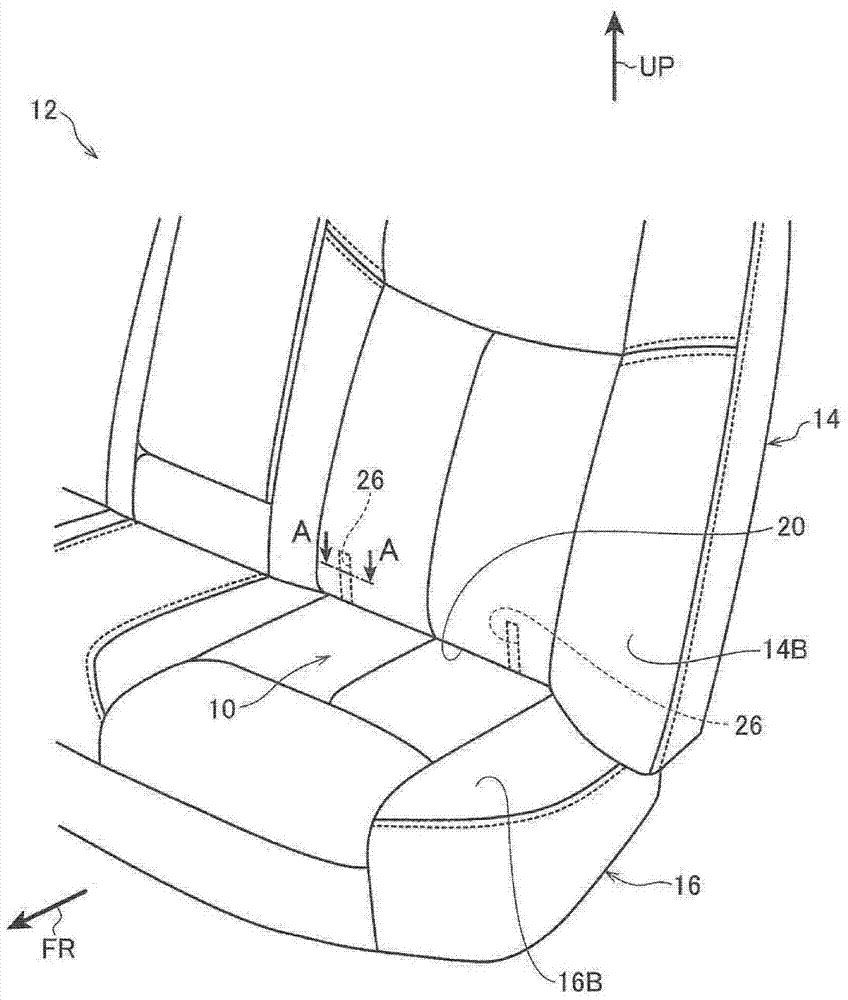

[0038] refer to Figure 1 to Figure 8The structure of the child seat attachment part which concerns on 1st Embodiment of this invention is demonstrated. In these figures, the front side in the vehicle front-rear direction is indicated by arrow FR, and the upper side in the vehicle vertical direction is indicated by arrow UP. In addition, in the following description, when using front-rear and up-down directions, unless otherwise specified, they mean front and rear in the vehicle front-rear direction and up and down in the vehicle up-down direction.

[0039] Such as figure 1 As shown, the child seat mounting portion structure 10 of the present embodiment is applicable to the rear seat 12 of a vehicle. The rear seat 12 is a reclining type, and the seat back 14 is configured such that it can be reclined relative to the seat cushion 16 .

[0040] as well figure 2 As shown, the rear seat 12 of this embodiment is composed of a seat cushion 16, a seat back 14, and a headrest (no...

no. 2 approach

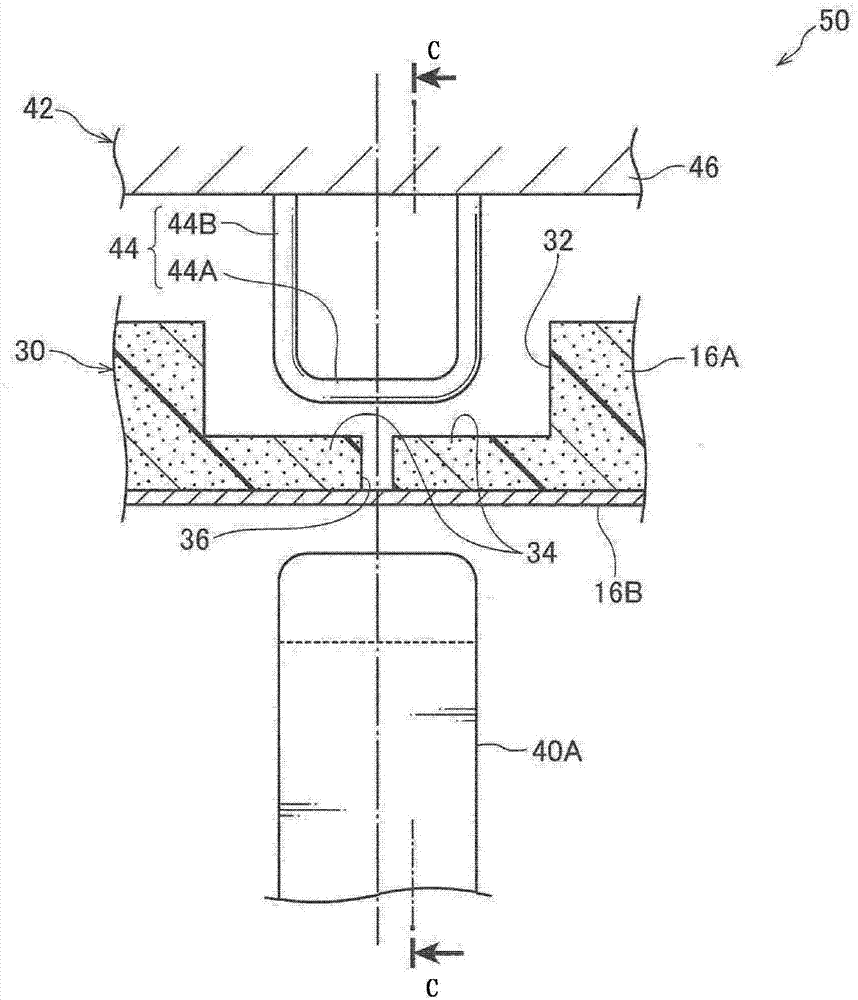

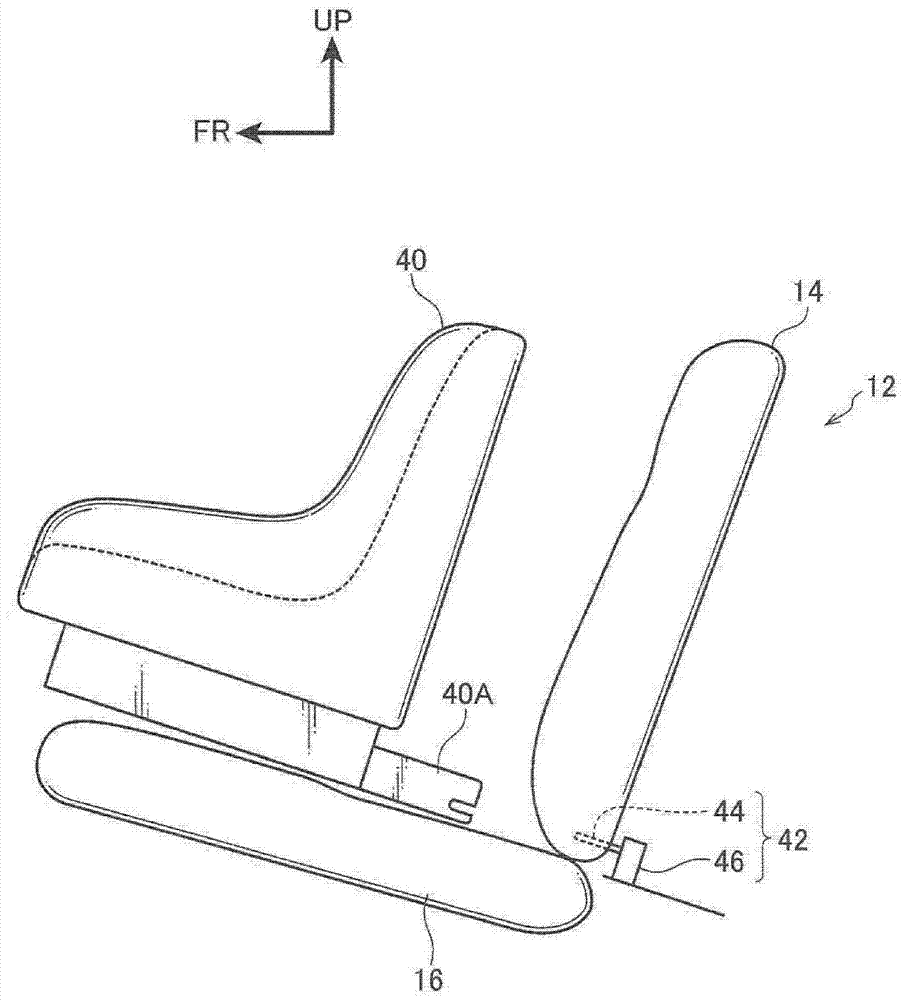

[0058] Next, refer to Figure 9 ~ Figure 12 A child seat attachment structure 50 according to a second embodiment of the present invention will be described. In addition, in this embodiment, the same parts as those in the first embodiment are assigned the same reference numerals, and detailed description thereof will be omitted.

[0059] In the present embodiment, a structure is adopted for inserting the connector 40A of the child seat 40 into the seat cushion 16 instead of the seat back 14 of the rear seat 12 .

[0060] Such as Figure 9 As shown, at the rear end of the seat cushion 16, a rising portion 30 rising upward is formed. The standing portion 30 is configured as a part of the seat cushion 16, and its appearance is formed by the cushion cushion portion 16A. Recesses 32 are formed at positions corresponding to the respective lower anchors 42 in the cushion cushioning portion 16A of the standing portion 30 . The concave portion 32 has a concave shape by reducing the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com