Stroke control device of press machine of automobile sheet metal component

A technology for automobile sheet metal parts and stroke control, applied in the direction of presses, manufacturing tools, etc., can solve the problems of insufficient yield rate and excessive press pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

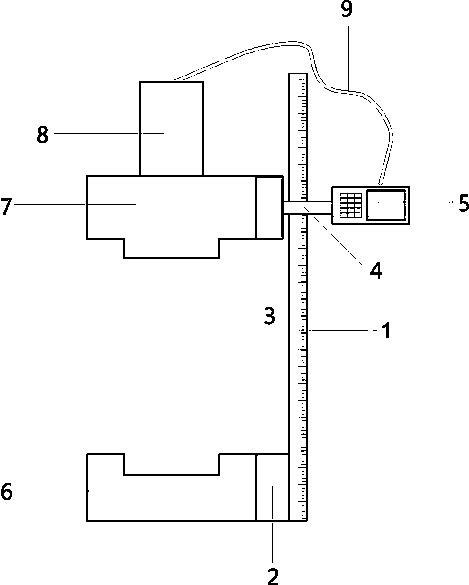

[0011] This embodiment provides a stroke control device for an automobile sheet metal parts press, such as figure 1 As shown, the scale 1 is fixedly installed on the ground or platform, and the bottom of the scale 1 is connected and fixed with the die 6 through the lower fixing plate 2. The height of the scale 1 is 3 meters, and there is a scale in millimeters on the scale. A freely slidable cursor 4 is provided, the left side of the cursor 4 is connected and fixed with the punch 6 through the upper fixing plate 3, the right side of the cursor 4 is provided with a control / output panel 5, the top of the punch 6 is connected and fixed with the press 8, and the press 8 can drive the punch 7 to move up and down, the control / output panel 5 and the press 8 are connected through the signal transmission line 9 for data transmission, and the press 8 is controlled by PLC programming for precise pressure adjustment.

[0012] When the press 8 drives the punch 7 to move, the punch 7 drives...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com