Laser welding fixture for gear

A technology for laser welding fixtures and gears, applied in laser welding equipment, welding equipment, welding equipment, etc., can solve the problem of reducing welding accuracy and processing efficiency, lack of clamping mechanism between ring gear and web, and difficult to ensure the concentricity of ring gear, etc. It can improve the welding accuracy and welding efficiency, prevent welding deformation, and achieve the effect of easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

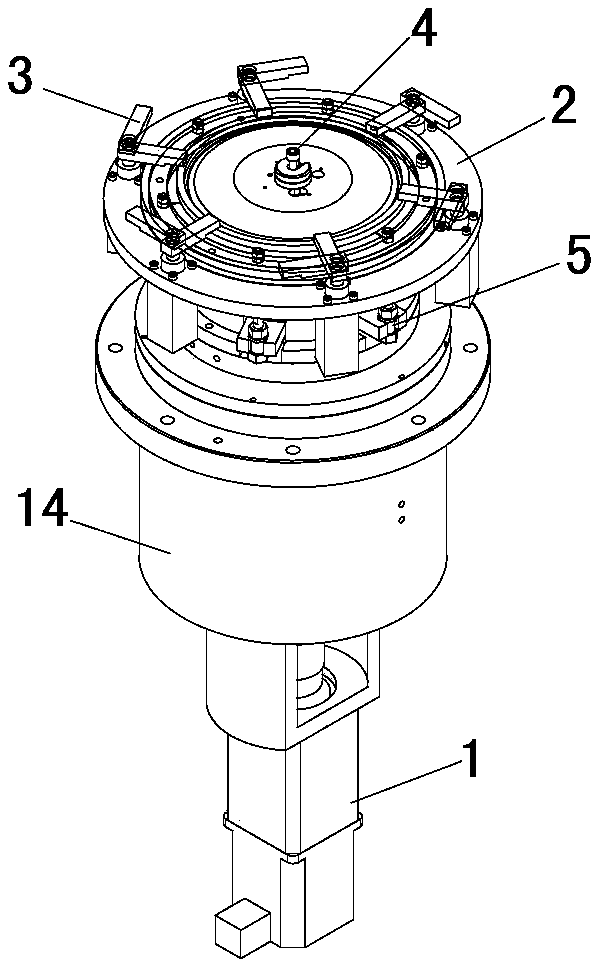

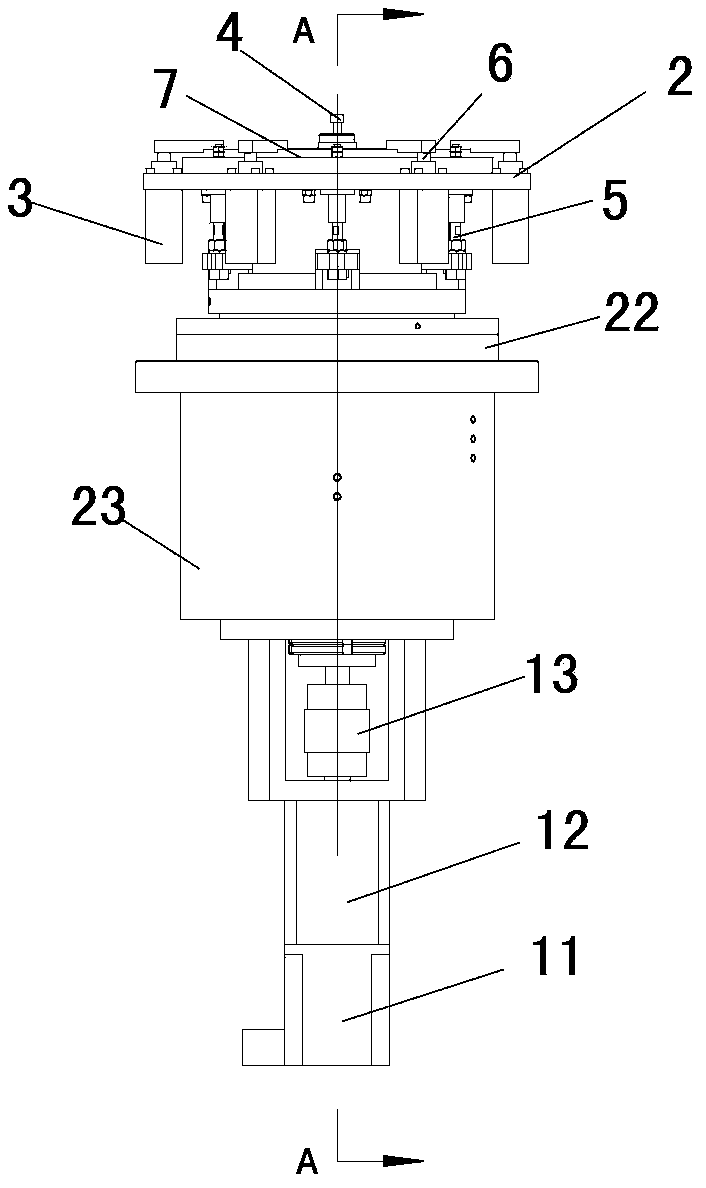

[0018] see figure 1 , figure 2 , image 3 , Figure 4 , The gear laser welding jig of the present invention includes a power rotation mechanism 1, a welding platform 2, a ring gear clamping mechanism 3, a web clamping mechanism 4 and a ring gear tightening mechanism 5. The welding platform 2 is connected to the power rotation mechanism 1 by fixed transmission, the ring gear clamping mechanism 3 is installed on the welding platform 1 to clamp the ring gear 6 in the axial direction, and the radial plate clamping mechanism 4 is installed on the welding platform 1 to clamp the radial plate 7 Implement axial clamping, and the ring gear tightening mechanism 5 is installed on the welding platform 1 to implement radial clamping on the ring gear 6 .

[0019] The power rotating mechanism 1 includes a servo motor 11 , a reducer 12 , an elastic coupling 13 and a turntable 14 sequentially connected from bottom to top; the welding platform 2 is connected to the turntable 14 through fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com