Landfill gas collection and exhaust guide system of landfill

A technology for landfill gas and landfill, which is applied in the field of landfill gas collection, guidance and drainage systems, can solve problems such as obvious differences in landfill gas extraction and drainage flow, pressure imbalance, etc., so as to avoid difficulties in subsequent treatment and utilization, and The effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

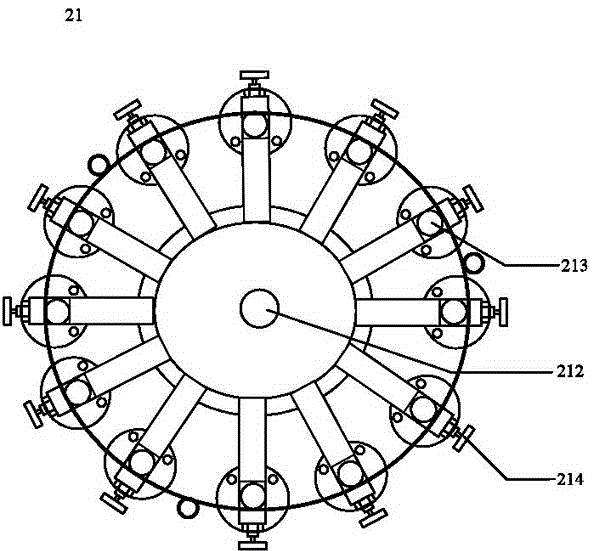

[0025] Such as figure 2 As shown, the landfill gas collection and drainage system 20 of the landfill in this embodiment includes: a plurality of gas gathering stations 21 arranged on the landfill, a gas transmission main pipe 22, an exhaust fan 23 and a landfill gas Centralized processing device 24. Each of the gas-gathering stations 21 includes a plurality of gas-gathering wells 211 and a main gas pipeline 212, and each of the gas-gathering wells 211 is connected to the gas pipeline through a gas-transmission branch pipe 213 and the gas pipeline 212 in turn. A gas main pipe 22, the gas transmission main pipe 22 is connected with the landfill gas central processing device 24 through the exhaust fan 23.

[0026] For each gas gathering station 21 , the connection with each gas gathering well 211 is realized through the main gas transmission pipe 212 and the gas transmission branch pipe 213 . Such as image 3 As shown, in order to ensure that each gas transmission main pipe 2...

Embodiment 2

[0032]The difference between this embodiment and Embodiment 1 is that a data processing center is added to the landfill gas collection and drainage system, and the methane concentration data of each gas collection well on the landfill is remotely transmitted to the data processing center. In this way, remote real-time monitoring of landfill gas collection is realized. The landfill gas collection and drainage system of this embodiment will be described in detail below, and the parts that are the same as those in Embodiment 1 will not be repeated.

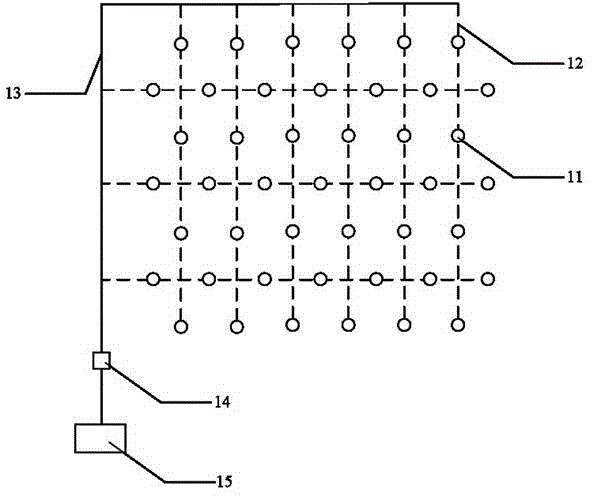

[0033] Specifically, as Figure 5 and Figure 6 As shown, the landfill gas collection and drainage system 30 in this embodiment includes a plurality of gas gathering stations 31, and each of the gas gathering stations 31 includes a plurality of gas gathering wells 311 and a main gas pipeline 312, each The gas collection wells 311 are connected to the main gas transmission pipe 312 through a gas transmission branch pipe 313, and a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com