Preparation device and preparation method for ultrafine CL-20

A CL-20, preparation device technology, applied in chemical instruments and methods, dissolution, grain processing, etc., can solve the problems of poor particle size control, high cost, heavy pollution, etc., to avoid potential threats and realize remote control and adjustment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] The preparation device of ultrafine CL-20 of the present invention is specifically as follows:

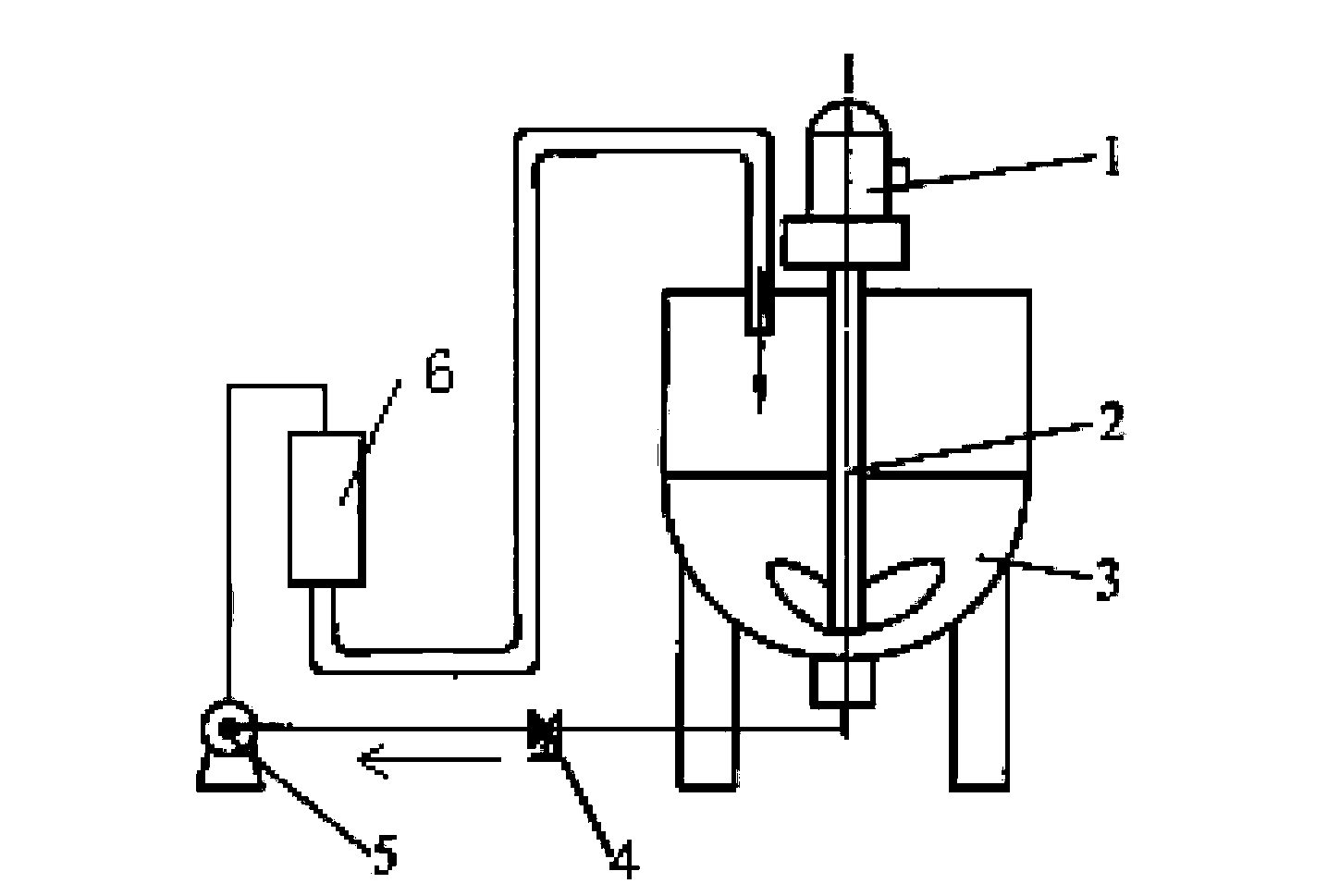

[0061] Such as figure 1 As shown, the preparation device of ultrafine CL-20 of the present invention includes a ball mill host 6, a mixer 3 and a material pump 5 connected to the ball mill host 6 by pipelines.

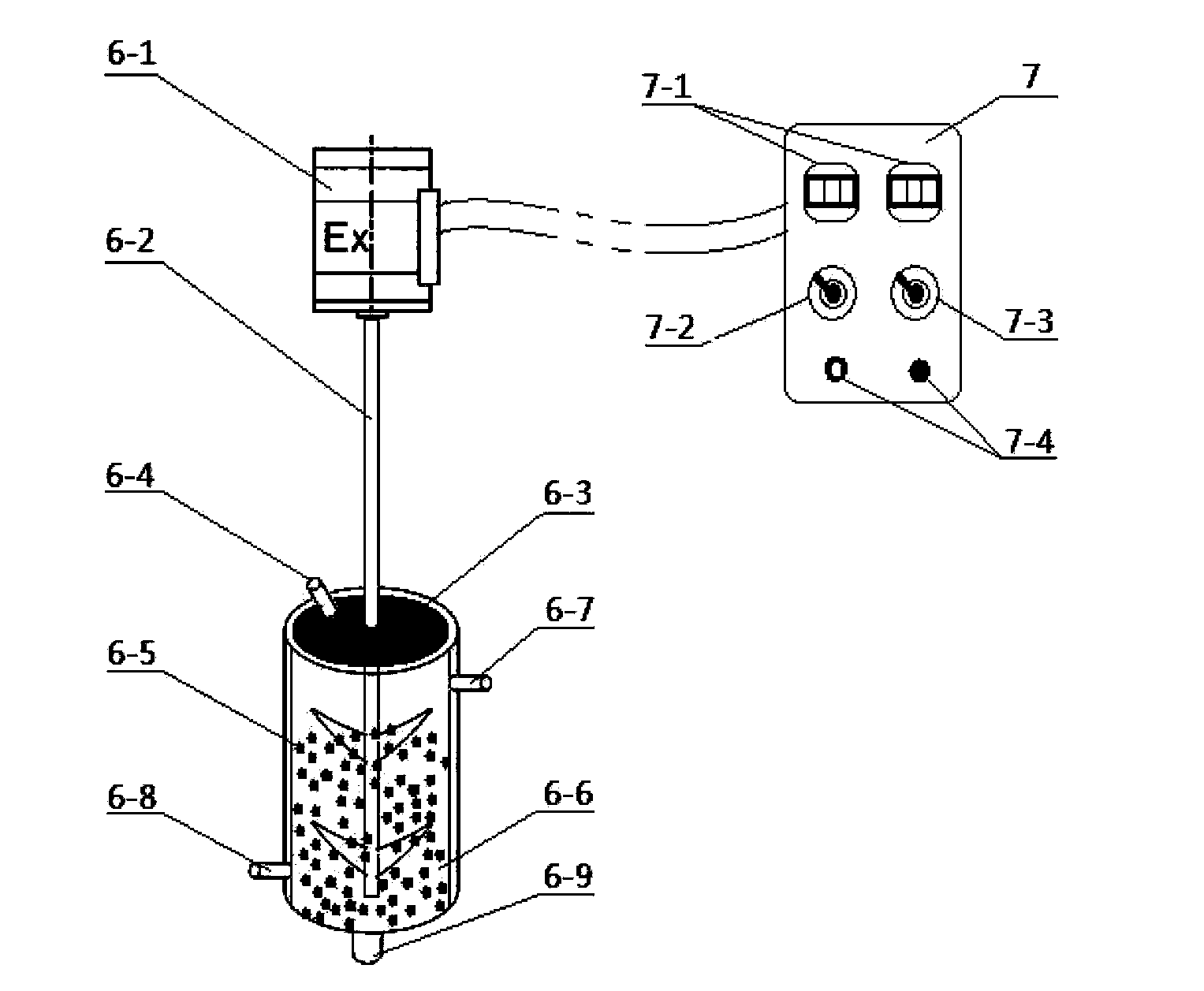

[0062] Such as figure 2 As shown, the ball mill host 6 includes a grinding chamber 6-6 with stirring, a grinding chamber upper cover 6-3, and grinding balls 6-5; the grinding chamber 6-6 is a cavity structure with an upper opening, and the grinding chamber upper cover 6 -3 Utilize the spring clip to fasten on the top of the grinding chamber 6-6 to cover its upper opening, and a rubber ring is arranged between the grinding chamber upper cover 6-3 and the upper opening of the grinding chamber 6-6 to cover its upper opening for sealing; grinding The chamber upper cover 6-3 is provided with a grinding chamber feed port 6-4, the bottom of the grinding chamber 6-6 is pr...

Embodiment 1

[0073] (1) Weigh 3.5kg of zirconia grinding balls (zirconium oxide purity 99.9%, sphericity 0.99) into the grinding chamber, the diameter of the grinding balls is 4mm, and the filling rate is 75%.

[0074] (2) Weigh 350g of raw material CL-20, measure 0.65L of grinding solution (distilled water) in a mixer with stirring, and stir well so that the two are fully mixed in the mixer to form a uniform CL-20 slurry. CL-20 slurry concentration is 35%wt.

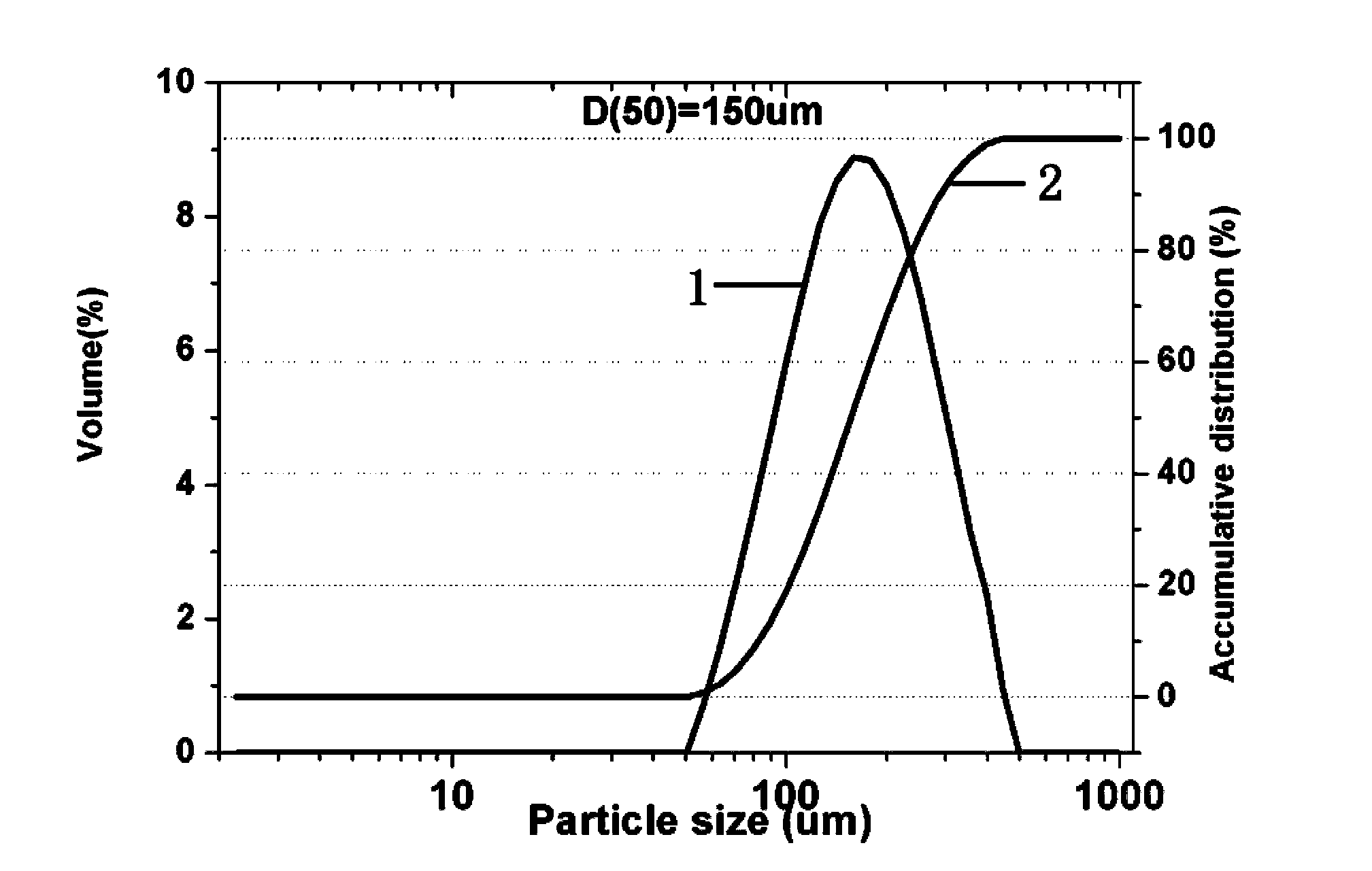

[0075] (3) Input the above CL-20 slurry from the mixer through the circulation device (connect the pipeline between the mixer and the grinding chamber and the material pump on it) into the grinding chamber for circulating crushing and grinding: CL-20 slurry Enter the grinding chamber from the feeding port on the top of the grinding chamber for crushing and grinding, and then discharge it to the mixer from the outlet at the bottom of the grinding chamber, and then re-input the slurry into the grinding chamber through the circulation ...

Embodiment 2

[0079] (1) Weigh 3.75 kg of grinding balls (same as in Example 1) and add them to the grinding chamber. The diameter of the grinding balls is 8 mm, and the filling rate is 80%.

[0080] (2) Weigh 350g of raw material CL-20, measure 0.65L of grinding solution (distilled water) in a mixer with stirring, and stir well so that the two are fully mixed in the mixer to form a uniform CL-20 slurry. CL-20 slurry concentration is 35%wt.

[0081] (3) Input the above CL-20 slurry from the mixer through the circulation device (connect the pipeline between the mixer and the grinding chamber and the material pump on it) into the grinding chamber for circulating crushing and grinding: CL-20 slurry Enter the grinding chamber from the feeding port on the top of the grinding chamber for crushing and grinding, and then discharge it to the mixer from the outlet at the bottom of the grinding chamber, and then re-input the slurry into the grinding chamber through the circulation device for circular ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com