Novel fastener-holing machine with improved material pushing mechanism

A technology of a pushing mechanism and a feeding mechanism, which is applied in the direction of sewing tools and other directions, can solve the problems of poor operability and controllability, rationality defects, low buttoning efficiency, etc., and achieve good buttoning quality and practicality. Strong and smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] In order to further explain the technical solutions of the present invention, specific examples are given below to illustrate in detail.

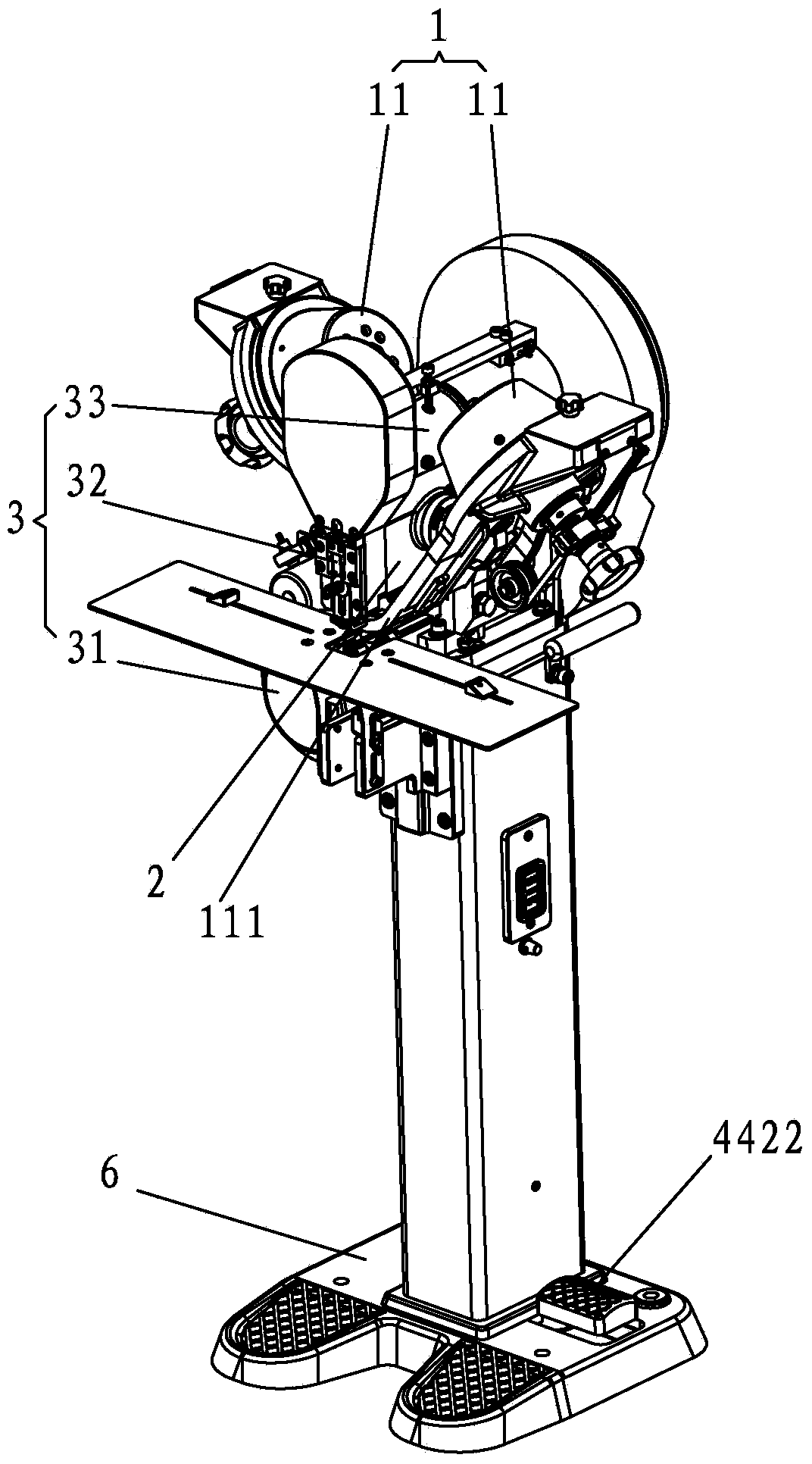

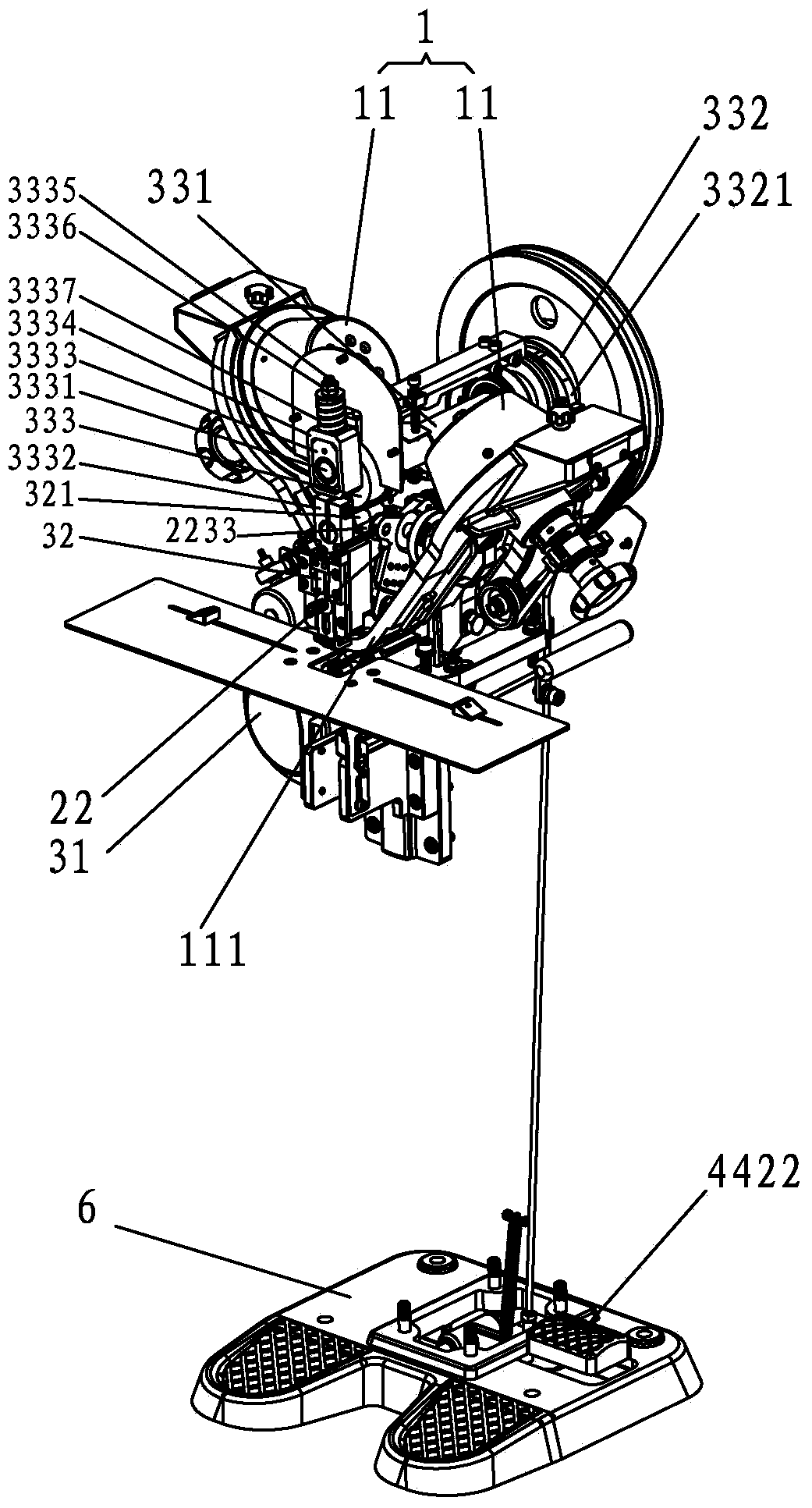

[0064] A kind of novel clasp machine that improves pusher mechanism of the present invention, as Figure 1-10 As shown, the buckle machine body is included, and the buckle machine body has a feeding mechanism 1, a pushing mechanism 2, a buckle mechanism 3 and a control mechanism 4 for controlling the buckle mechanism 3.

[0065] The feeding mechanism 1 includes two feeding boxes 11, and two upper feeding passages 111 and lower feeding passages 112 that are respectively communicated with the two feeding boxes 11 to convey materials; the pushing mechanism 2 includes corresponding upper feeding passages 111 and lower feeding passages. The discharge opening of passage 112 is provided with, pushes corresponding buckle material to the buckle seat 5 places on the buckle machine body and buckles the pusher device 21, and the pusher transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com