Epicyclic reduction gear

A planetary gear reduction and planetary gear technology, applied in the field of planetary gear reduction devices, can solve the problems affecting the compactness of the planetary gear reduction device, inconvenient operation, poor stability, etc., and achieve the effect of easy operation, good stability and space assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

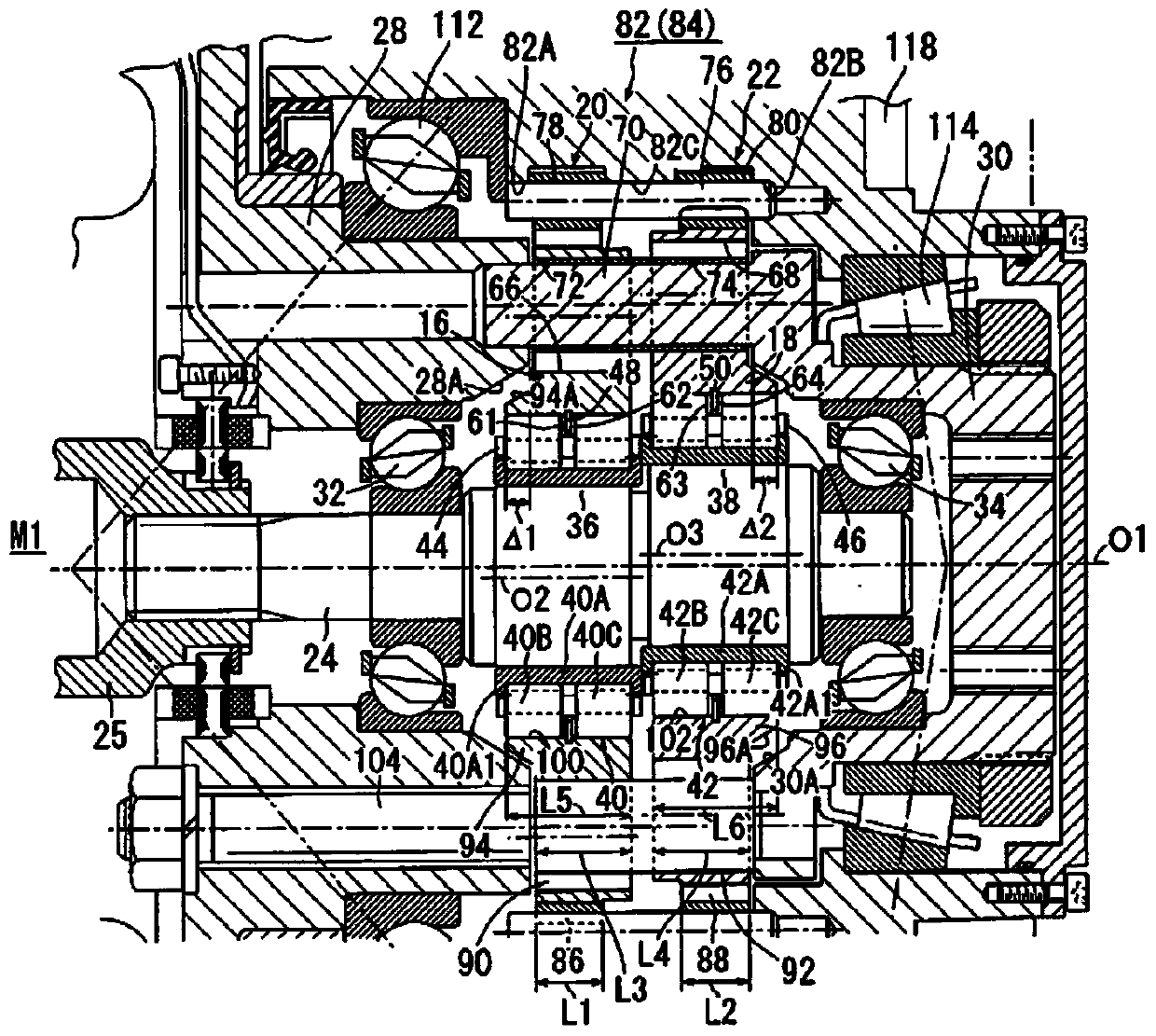

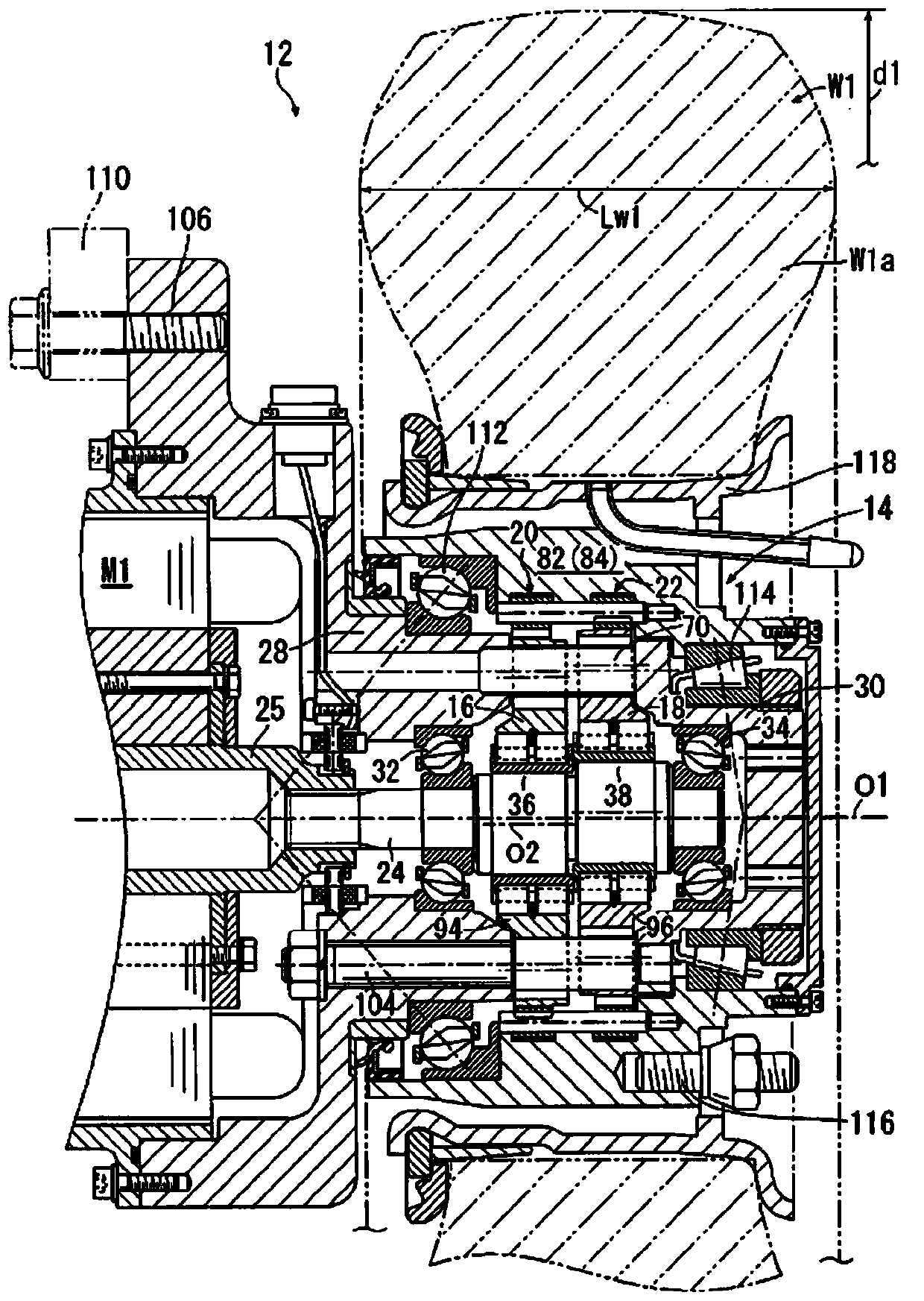

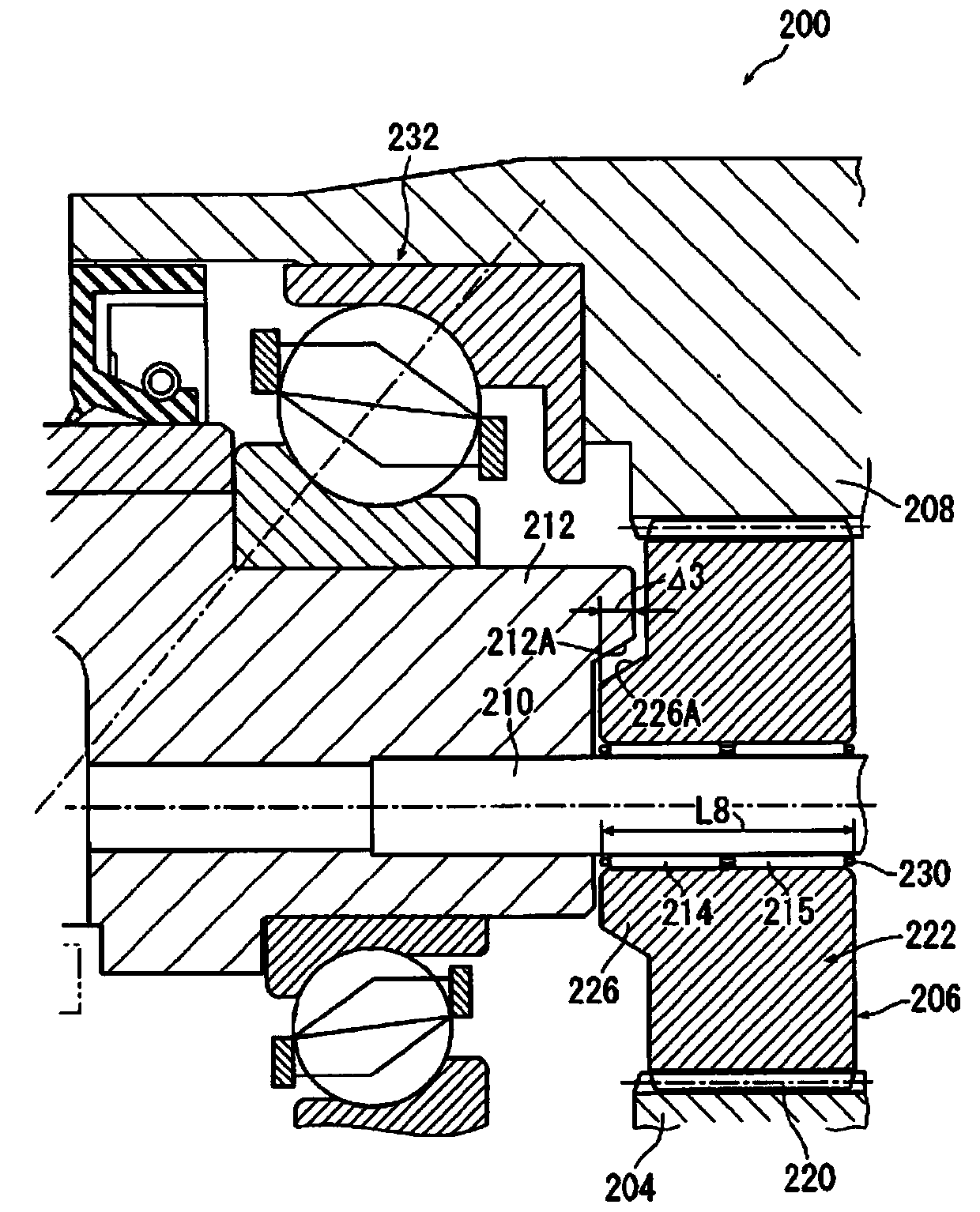

[0021] Hereinafter, an example of the embodiment of the present invention will be described in detail with reference to the drawings.

[0022] figure 1 It is a sectional view of main parts showing an example of an embodiment in which the eccentric oscillating planetary gear reduction device according to the present invention is applied to the wheel drive of a forklift, figure 2 is an overall sectional view of the planetary gear reduction unit.

[0023] The wheel W1 of the forklift (not shown in its entirety) 12 serves as a "fulcrum" for supporting cargo. Therefore, in order to make the position of the fork (not shown) constituting the "power point" or "action point" as close as possible to the ground contact point of the wheel W1, the outer diameter d1 of the wheel W1 should be as small as possible. In addition, in order to reliably bear the load of the cargo, the larger the volume of the tire portion (rubber portion) W1a of the wheel W1, the better. Therefore, only a very...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com