Fire hose abrasion test device

A wear-resistant test, water belt technology, applied in the direction of testing wear resistance, etc., can solve the test equipment can not meet the requirements of the hose performance test, can not test the water belt wear resistance and other problems, to achieve accurate X-direction moving speed and movement The effect of distance and pressure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

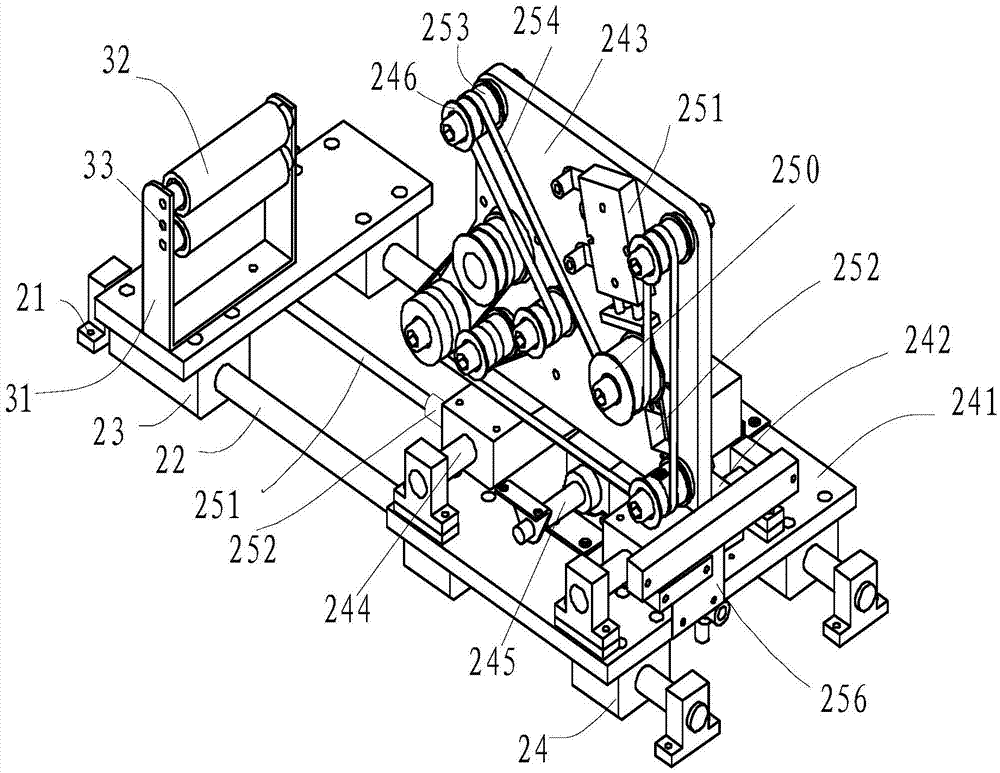

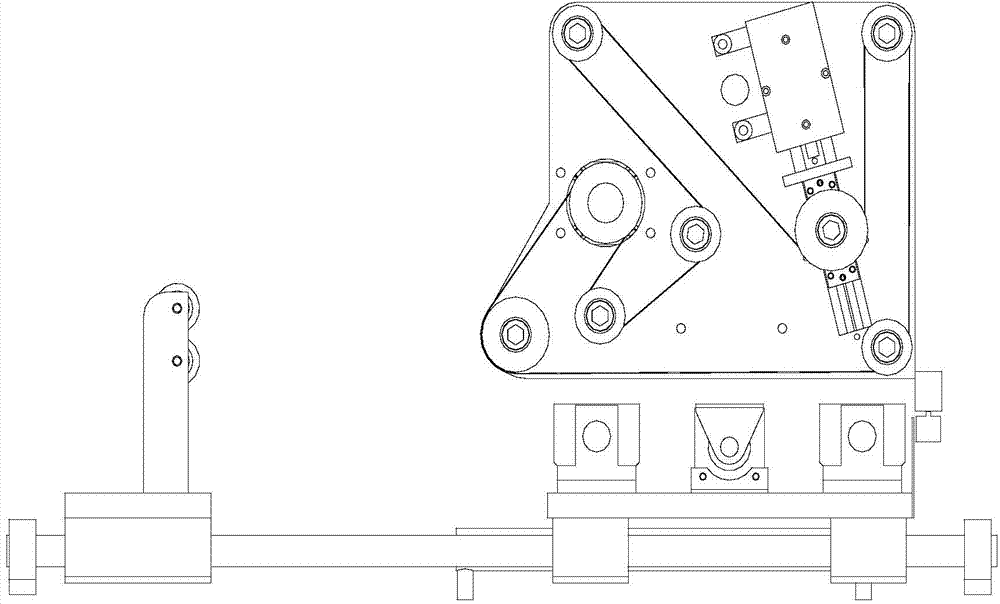

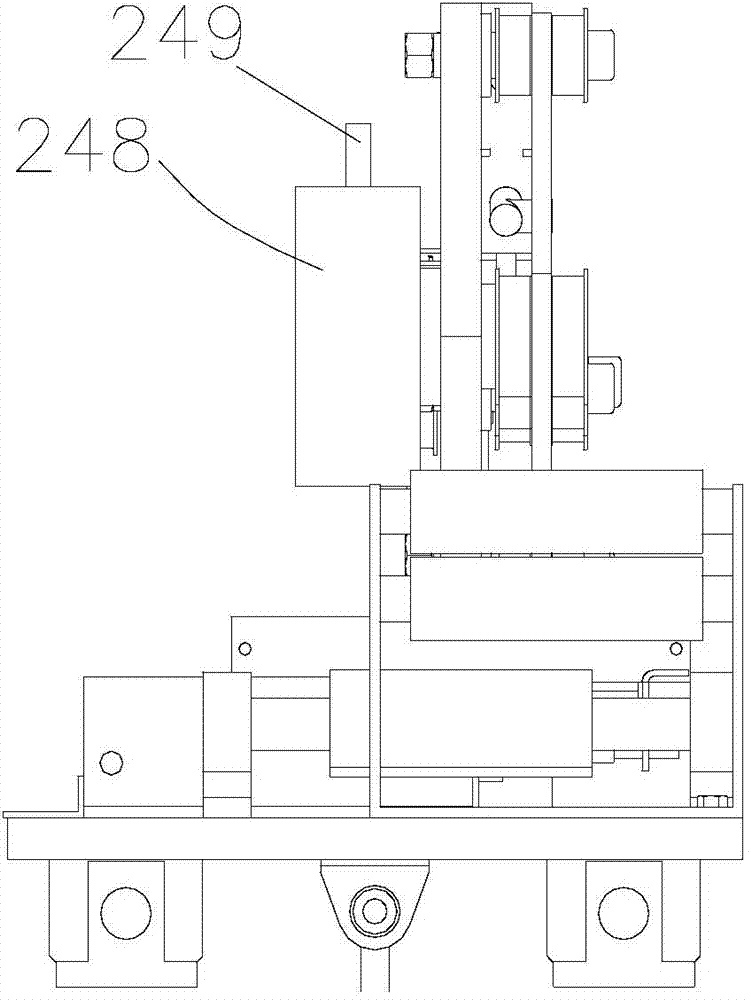

[0020] Such as Figure 1 to Figure 3 As shown, a water hose wear test device includes a connecting platform 21 connected to the machine body. The connecting platform 21 is provided with a Y-direction guide shaft 22, and the Y-direction guide shaft 22 is provided with a Guide slider A23, guide slider B24, described guide slider A23, guide slider B24 are connected by Y to the moving cylinder, guide slider A23 is connected with the connecting rod 251 of Y to the moving cylinder in the present invention, guide slider B is connected with the cylinder block 252, the guide slider A23 is provided with a support frame A31, the support frame A31 is provided with two hose support wheels 32, the guide slider B24 is provided with a first support plate 241, the first support plate 241 The second sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com