Bullet firing device of Hopkinson pressure bar

A technology of Hopkinson pressure rod and launching device, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as troublesome operation and waste of time, and achieve the effect of convenient loading and improved use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

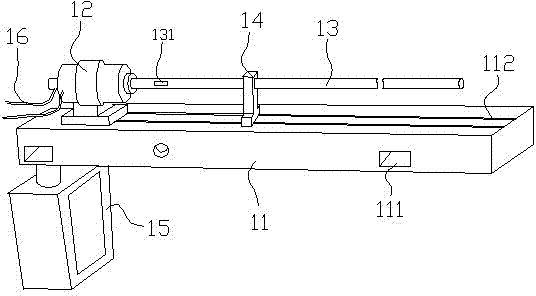

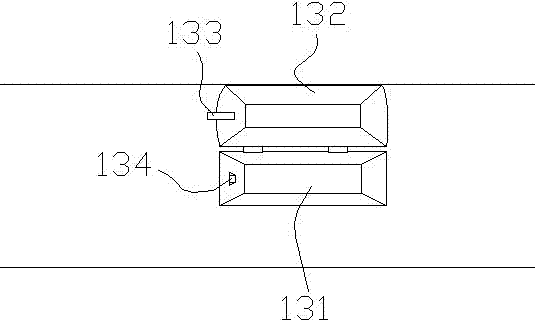

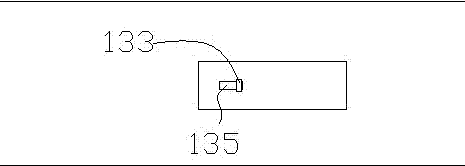

[0014] The specific embodiment of the present invention is described below in conjunction with accompanying drawing: the bullet launching device of a kind of Hopkinson pressure rod as shown in the figure, comprises support platform 11, the launch chamber 12 that is fixed on the support platform, the launch chamber that links to each other with launch chamber Pipe 13 and the base 15 of carrying support platform, firing cavity 12 is fixed on an end of support platform 11, and the extension direction of launch tube 13 is identical with the extension direction of support platform, and support platform 11 is provided with for supporting launch tube 13 along its length direction. The sliding bracket 14, and the supporting table is provided with a chute 112 along its extension direction, and the bottom of the sliding bracket 14 is provided with a protrusion corresponding to the chute 112. After the two are engaged, the sliding bracket 14 can be moved along the supporting table Sliding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com