Coaxial cable sensor and production method and use method thereof

A coaxial cable and sensor technology, applied in the field of stress sensors, can solve the problems of poor ability of catastrophic accidents, small dynamic range, and unsatisfactory monitoring, etc., and achieve the effects of good applicability, strong anti-interference ability, and good shielding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

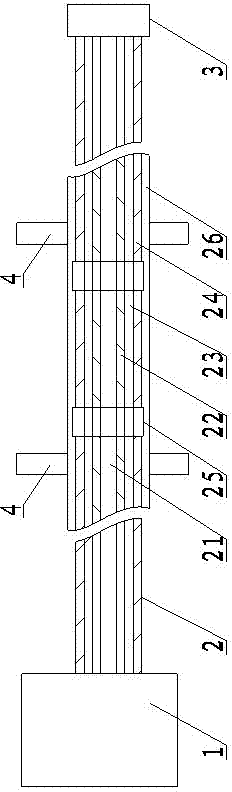

[0036] see figure 1 , the embodiment of the present invention includes:

[0037] A coaxial cable sensor includes a sensing unit and a modem 1 . The sensing unit includes a coaxial cable 2 , a metal needle and a packaging sleeve 26 . The coaxial cable 2 includes an inner conductor 21 , an outer conductor shielding layer 23 and an insulating plastic protective sleeve 24 . The outer conductor shielding layer 23 is located between the inner conductor 21 and the insulating plastic protective sleeve 24, the middle section of the insulating plastic protective sleeve 24 is provided with two openings, and the packaging sleeve 26 is sleeved on On the middle section of the insulating plastic protection sleeve 24, the metal needle is connected to the inner conductor 21 and the outer conductor shielding layer 23, and a part extends out of the opening to the packaging sleeve 26, so The opening and the metal needle together constitute the reflection point 25 of the coaxial cable 2, and th...

Embodiment 2

[0061] see figure 2 , the coaxial cable sensor described in Embodiment 2 of the present invention is different from the coaxial cable sensor described in Embodiment 1 in that: (1) the coaxial cable sensor does not include a characteristic matching load 3, and the coaxial cable sensor Both ends of the cable 2 are connected to the modem 1, and the coaxial cable 2 forms a loop, (2) different from the reflection mode in the embodiment 1, the work of the coaxial cable sensor in the embodiment 2 The mode used is transmission mode.

[0062] Another example figure 2 As shown, both ends of the coaxial cable 2 are connected to the modem 1, the coaxial cable 2 forms a loop, and the middle section of the coaxial cable 2 includes two reflection points 25. Similarly, the coaxial cable The axial cable 2, the reflection point 25 and the packaging sleeve 26 together constitute the sensing unit of the coaxial cable sensor.

[0063] The manufacturing method of the coaxial cable sensor descr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com