Renovation Structure and Construction Method of Old Factory Building by Adding Stories

A technology for transforming structures and old factory buildings, applied in building structure, building maintenance, construction, etc., can solve the problems of personnel and property loss, poor seismic performance, etc., and achieve the effect of low cost, overall stability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

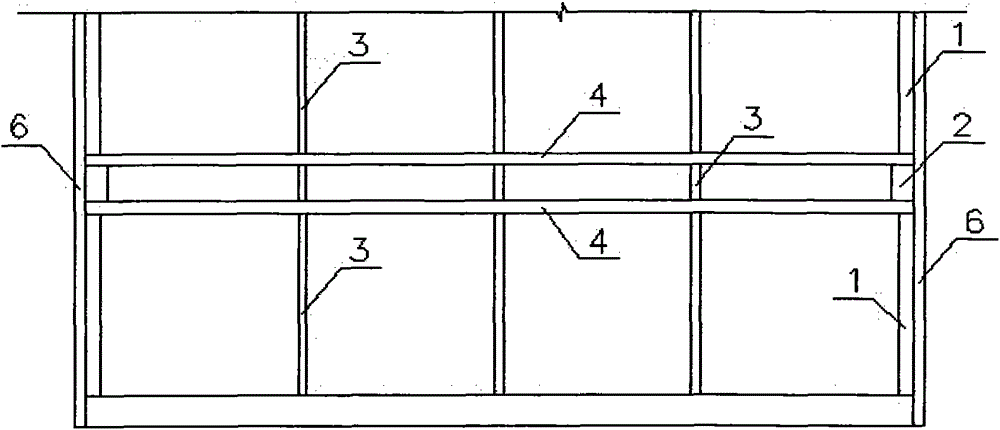

[0034] like Figure 1-5 As shown in the figure, an internal structure of an old factory building is reconstructed by adding floors, including the original structure of the old factory building, plus internal horizontal steel beams 4, plus internal longitudinal steel beams 3, plus internal steel columns 5, plus external steel columns 7, and plus external steel ring beams 6 and newly added concrete floor slab 12, plus internal longitudinal steel beam 3, plus internal transverse steel beam 4 and plus internal steel column 5 are welded and connected to form a grid steel frame; plus external steel column 7 and external steel ring beam 6 along the The exterior of the original structure is arranged and closed into a circle, and the ends of the additional internal transverse steel beam 4 pass through the outer wall 1 of the original structure, and are connected with the external steel column 7 and the external steel ring beam 6 through anchoring measures to form a closed steel frame as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com