Diatom ooze wall material with high content of diatomite and preparation method thereof

A technology of high diatomite and diatom mud, which is applied in the field of diatom mud wall materials and its preparation, can solve the problems of poor use effect, achieve simple and convenient operation, and improve the effect of human respiratory system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

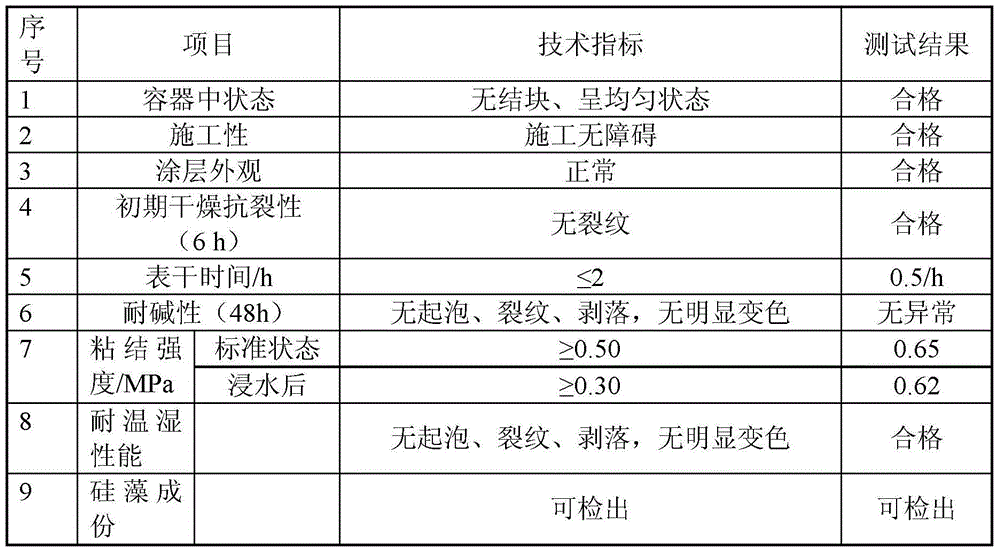

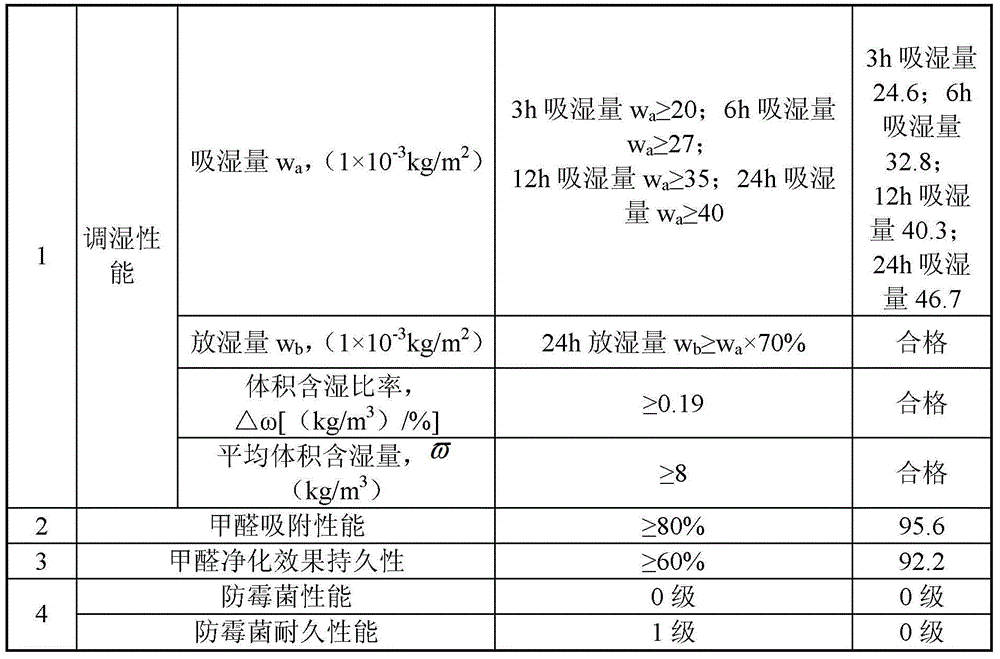

Examples

specific Embodiment approach 1

[0013] Specific embodiment one: The diatom ooze wall material with high diatomite content of the present embodiment consists of 40-55 parts by weight of diatomite, 2-5 parts of dispersible rubber powder (21#), 0.4-1 part of Hydroxypropyl methylcellulose ether, 2-8 parts of Portland cement, 5-15 parts of ash calcium powder, 5-15 parts of attapulgite powder, 10-25 parts of washed quartz sand, 1-5 parts Sericite powder, 3-10 parts of zeolite powder, 0.1-1 part of flax fiber, 0.1-1 part of nano-ZnO powder, 0.005-0.1 part of nano-silver particles, 0.1-1 part of silicone hydrophobic powder and 0.1 ~1 part of inorganic pigment; among them, diatomite is 200~600 mesh; white washed quartz sand is 40~200 mesh; sericite powder is 300~800 mesh; zeolite powder is 300~500 mesh; The particle size is 10-100 nanometers; the viscosity of hydroxypropyl methylcellulose ether is 50,000-100,000; the length of flax fiber is 0.3-1.5 cm.

[0014] The diatomite described in this embodiment is the first...

specific Embodiment approach 2

[0017] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the diatom ooze wall material with high diatomite content consists of 41 to 54 parts of diatom earth, 2.5 to 4.5 parts of dispersible rubber powder (21 #), 0.5-0.9 parts of hydroxypropyl methylcellulose ether, 3-7 parts of Portland cement, 6-13 parts of ash calcium powder, 6-13 parts of attapulgite powder, 12-22 parts of White washed quartz sand, 1.5-4.5 parts of sericite powder, 4-9 parts of zeolite powder, 0.2-0.9 parts of flax fiber, 0.2-0.9 parts of nano-ZnO powder, 0.01-0.05 parts of nano-silver particles, 0.2-0.9 parts It is made of 0.2-0.9 parts of organic silicon hydrophobic powder and 0.2-0.9 parts of inorganic pigments. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0018] Specific embodiment three: the difference between this embodiment and specific embodiment one is that the diatom ooze wall material with high diatomite content consists of 42 to 52 parts of diatom earth, 3 to 4 parts of dispersible rubber powder (21 #), 0.6-0.8 parts of hydroxypropyl methylcellulose ether, 4-6 parts of Portland cement, 7-12 parts of ash calcium powder, 7-12 parts of attapulgite powder, 15-20 parts of White washed quartz sand, 2-4 parts of sericite powder, 5-8 parts of zeolite powder, 0.3-0.8 parts of flax fiber, 0.3-0.8 parts of nano-ZnO powder, 0.02-0.05 parts of nano-silver particles, 0.3-0.8 parts It is made of 0.3-0.8 parts of organic silicon hydrophobic powder and 0.3-0.8 parts of inorganic pigments. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com