Anti-puncturing tyre and preparation method thereof

A puncture-proof technology for tires, applied to tire parts, reinforcement layers of pneumatic tires, tires, etc., can solve problems such as high cost, low production efficiency, and unsatisfactory anti-puncture effects, and achieve low cost and high production efficiency , Good anti-puncture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

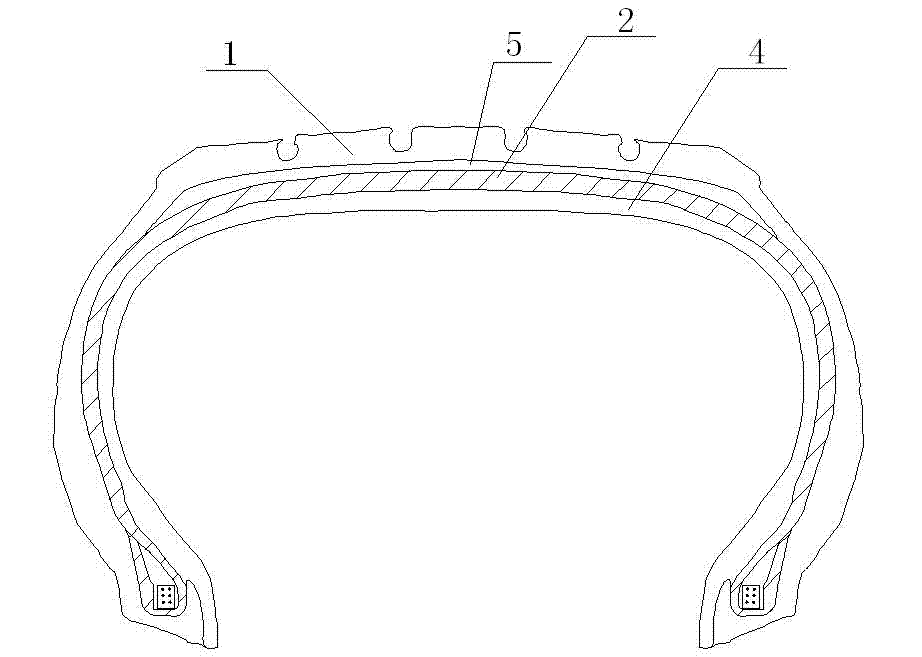

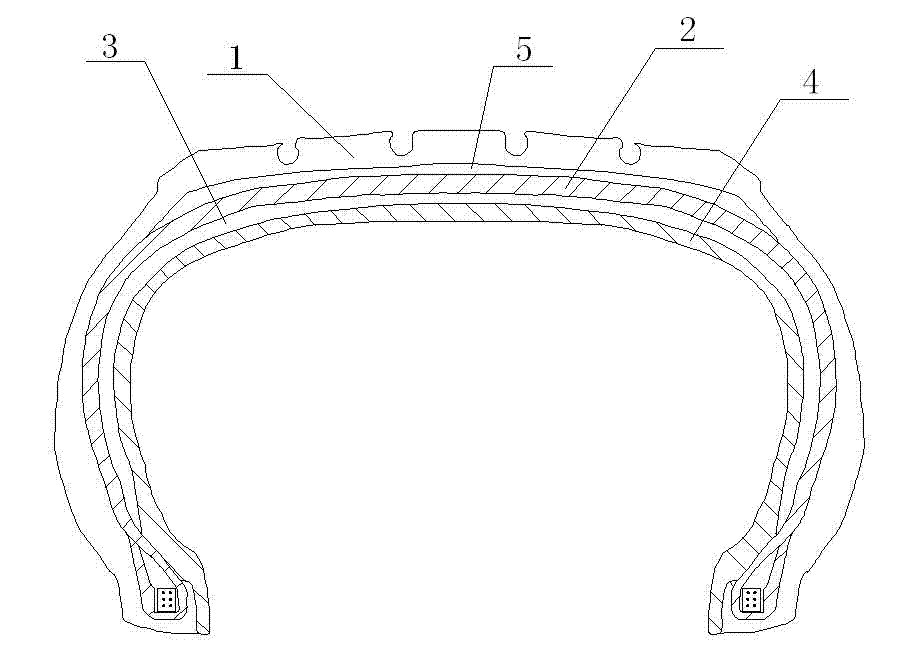

[0044] refer to figure 2 , a puncture-resistant tire, which is provided with an airtight layer 4, a carcass layer 2, a belt layer 5 and a tread 1 in sequence from the inside to the outside, and a rubber layer is arranged between the airtight layer 4 and the carcass layer 2 The self-sealing layer 3, the rubber self-sealing layer 3 is fully covered on the carcass layer 2. The thickness of the rubber self-sealing layer is 0.5mm, and the thickness of the airtight layer is 2.2mm; the ply is a steel ply, and the number of layers of the steel ply is 3 layers.

[0045] The rubber self-sealing layer 3 is prepared from polyacrylic resin and polyurethane adhesive in a weight ratio of 1:0.98. Polyurethane has good physical and mechanical properties, excellent cold resistance, elasticity, high gloss, and softness and hardness do not change much with temperature, and is resistant to organic solvents. However, polyurethane resin coating has poor water resistance and mechanical strength is ...

Embodiment 2

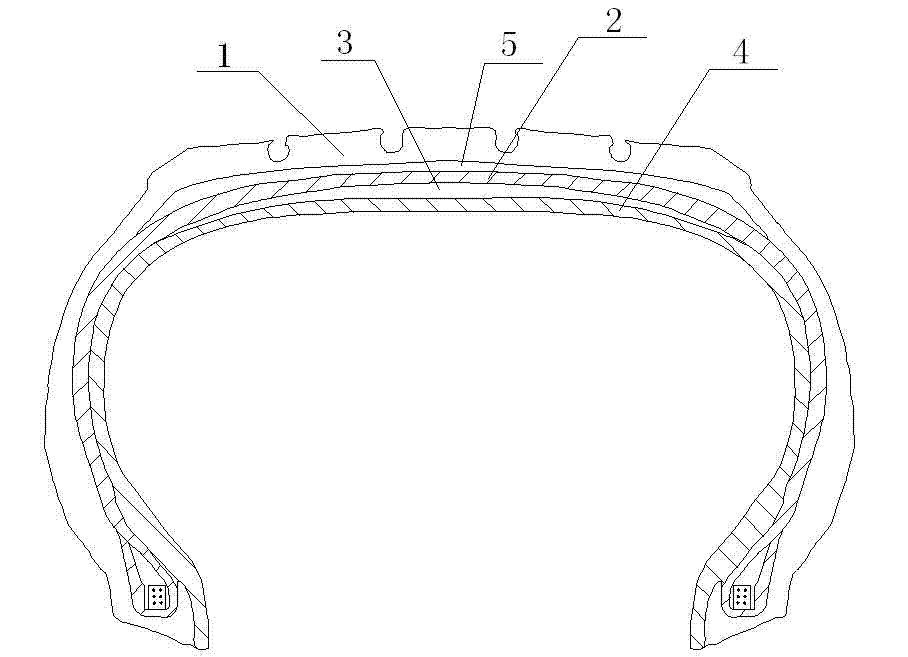

[0056] refer to image 3 , a puncture-resistant tire, which is provided with an airtight layer 4, a carcass layer 2, a belt layer 5 and a tread 1 in sequence from the inside to the outside, and a rubber layer is arranged between the airtight layer 4 and the carcass layer 2 The self-sealing layer 3 , the rubber self-sealing layer 3 partially covers the carcass layer 2 . The thickness of the rubber self-sealing layer is 1.2mm, and the thickness of the airtight layer is 1.2mm. The cord layer is a steel cord layer, and the number of layers of the steel cord layer is 5 layers.

[0057] The rubber self-sealing layer 3 is prepared from polyurethane, polyamide and EVA hot-melt adhesives with a weight ratio of 1:0.9:0.25. The compounded rubber self-sealing layer material has excellent initial adhesion, holding strength and resilience. The airtight layer is prepared with bromobutyl rubber as the main body, adding carbon black, silicon dioxide, aluminum, rubber dispersant, and sulfur,...

Embodiment 3

[0068] refer to figure 2 , a puncture-resistant tire, which is provided with an airtight layer 4, a carcass layer 2, a belt layer 5 and a tread 1 in sequence from the inside to the outside, and a rubber layer is arranged between the airtight layer 4 and the carcass layer 2 The self-sealing layer 3, the rubber self-sealing layer 3 is fully covered on the carcass layer 2. The thickness of the rubber self-sealing layer is 1.8mm, and the thickness of the airtight layer is 0.9mm. The cord layer is a steel cord layer, and the number of layers of the steel cord layer is 3 layers.

[0069] The rubber self-sealing layer 3 is prepared from polyacrylic resin adhesive. The airtight layer is mainly made of bromobutyl rubber, and prepared by adding white carbon black, mica, rubber dispersant, and sulfur, wherein the weight ratio of bromobutyl rubber, white carbon black, mica, rubber dispersant, and sulfur is 1:0.3:2.1:0.03:0.02.

[0070] The anti-puncture tire is prepared by the follow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com