Method for machining threaded rod through lathe

A lathe processing and screw technology, which is applied to metal processing equipment, manufacturing tools, thread cutting auxiliary equipment, etc., can solve the problems of unguaranteed screw finish and accuracy, screw deformation, and high rejection rate, and achieves simple, reliable, and easy-to-operate processing methods. , Improve the effect of screw precision and smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

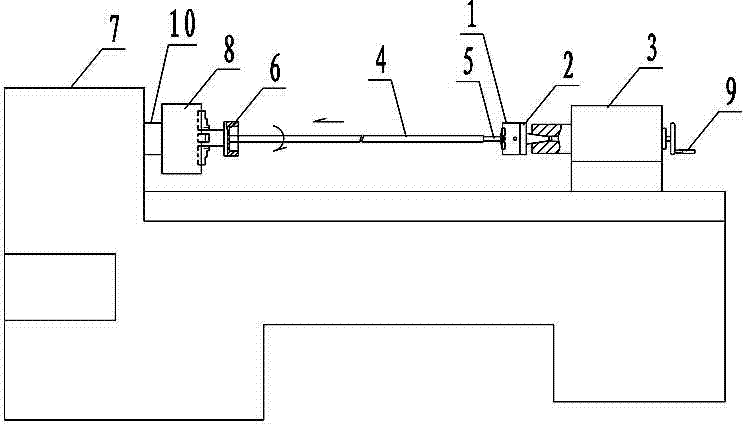

[0014] Such as figure 1 , 2 As shown in 3, the method of using a lathe to process a screw according to the present invention is carried out according to the following steps:

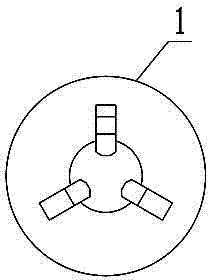

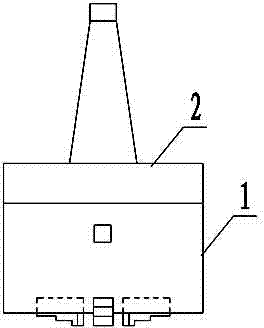

[0015] The first step is to fix the three-jaw chuck 1 on the conical mold handle 2, and install the three-jaw chuck 1 on the tailstock 3 of the lathe through the conical mold handle 2;

[0016] The second step is to turn a truncated cone section 5 at one end of the screw 4 to be processed. The diameter of the truncated cone section 5 is smaller than the diameter of the thread bottom to be processed by 1 mm, and the length of the truncated cone section 5 is twice the thickness of the die + the three-jaw card The clamping length of disc 1;

[0017] The third step is to install the die on the head chuck 8 of the lathe 7 through the die sleeve 6, and the three-jaw chuck 1 on the tailstock 3 of the lathe clamps the circular table section 5 of the screw 4 to be processed. The other end of the screw 4 is chamfered an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com