Method for setting full-length tension of cold rolling processing line

A tension setting and setting method technology, applied in the field of cold-rolled strips, can solve problems such as frequent tension changes, achieve the effect of improving quality and output, and avoiding frequent tension changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The method for setting the overall tension of the cold rolling treatment line provided by the embodiment of the present invention includes the establishment of a tension setting model and the optimization of the acquisition of the tension setting value.

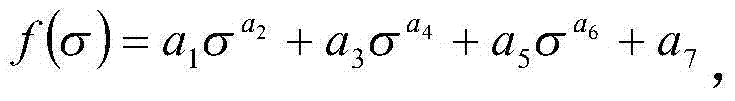

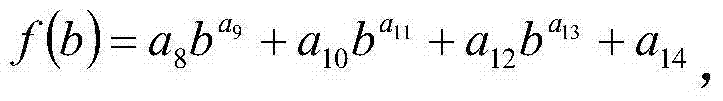

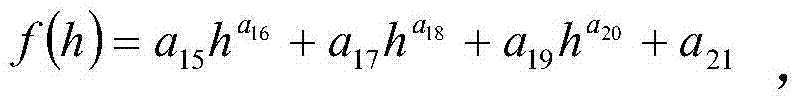

[0021] The establishment of the tension setting model is to establish a mathematical model formula by using instrumental regression for the tension values corresponding to different thicknesses and different widths of the existing tension gauge. Based on the function T=f(σ)f(b)f(h)f(b,h) as the basic model, the tension of each section is set, and the tension setting value of each section is calculated to obtain the tension table.

[0022] Take the uncoiler as an example, where,

[0023] f ( σ ) = a 1 σ a 2 + a 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com