Coil assembly for three phased transverse axial flux multi disk machines

A technology of coil components and coil components, which is applied in the direction of electric components, electrical components, and manufacturing of motor generators, etc., can solve the problems of difficult assembly, difficult to manufacture motors, winding coils, etc., and achieve good efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

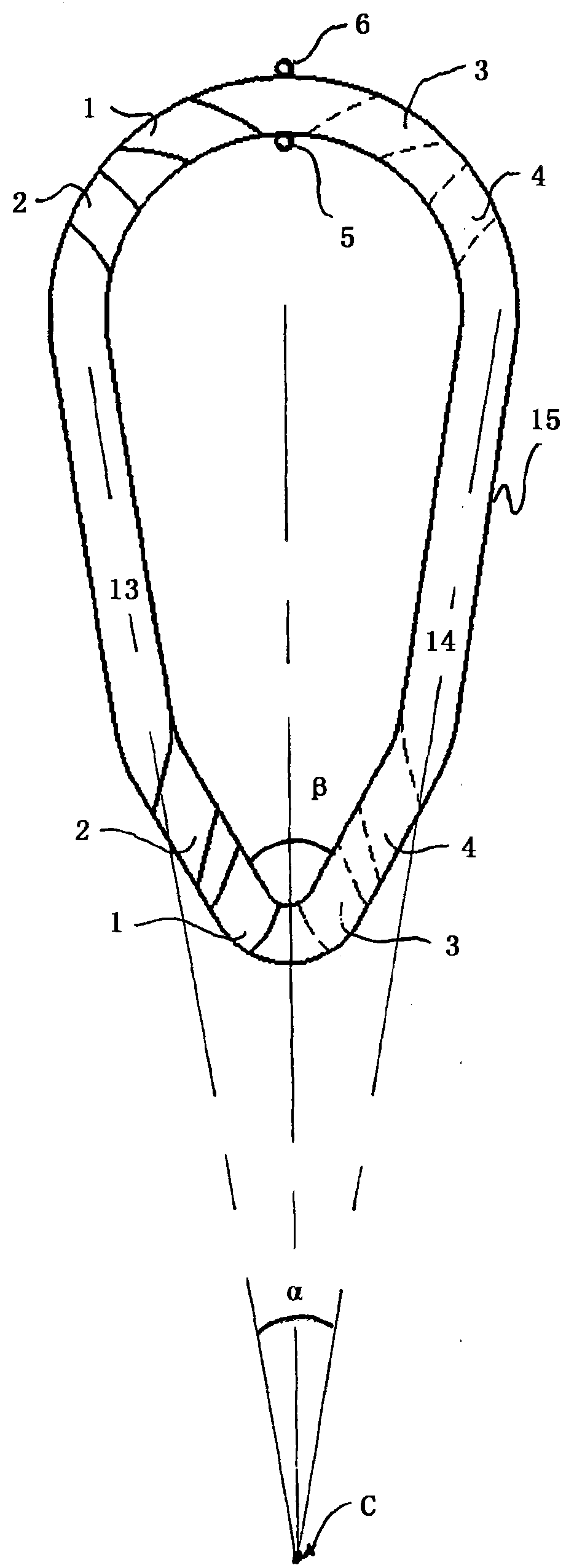

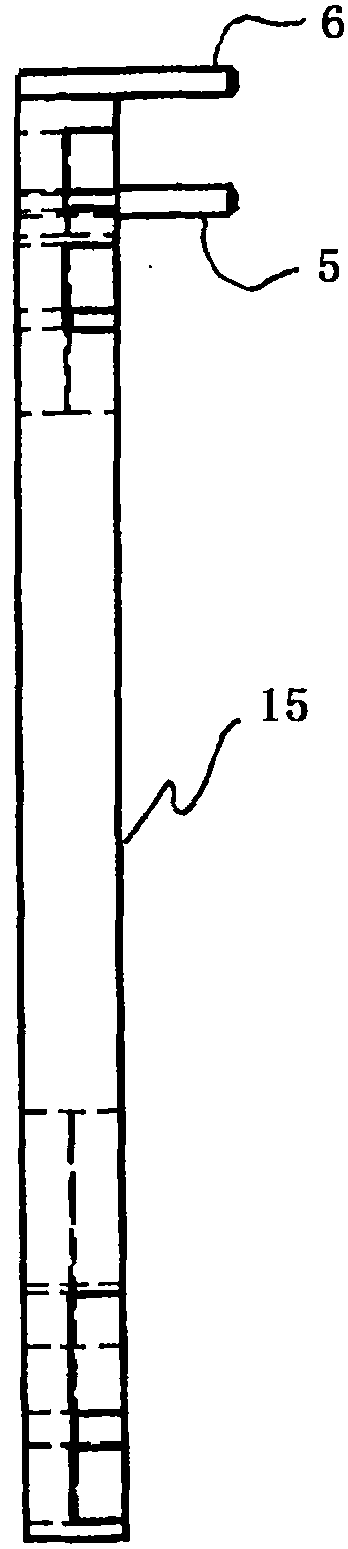

[0032] The type of motor for which the present invention is most suitable is the cross-axis flux ironless permanent magnet multi-disc motor, but the invention can be used for other types of motors as well. The machine defined by claim 1 is generic for electric machines with any number of phases, whereas the machine defined in claims 2 and 3 is used in particular for three-phase electric machines. The invention relates in particular to coil elements 15 which are suitable for mass production and are then assembled into compact coils.

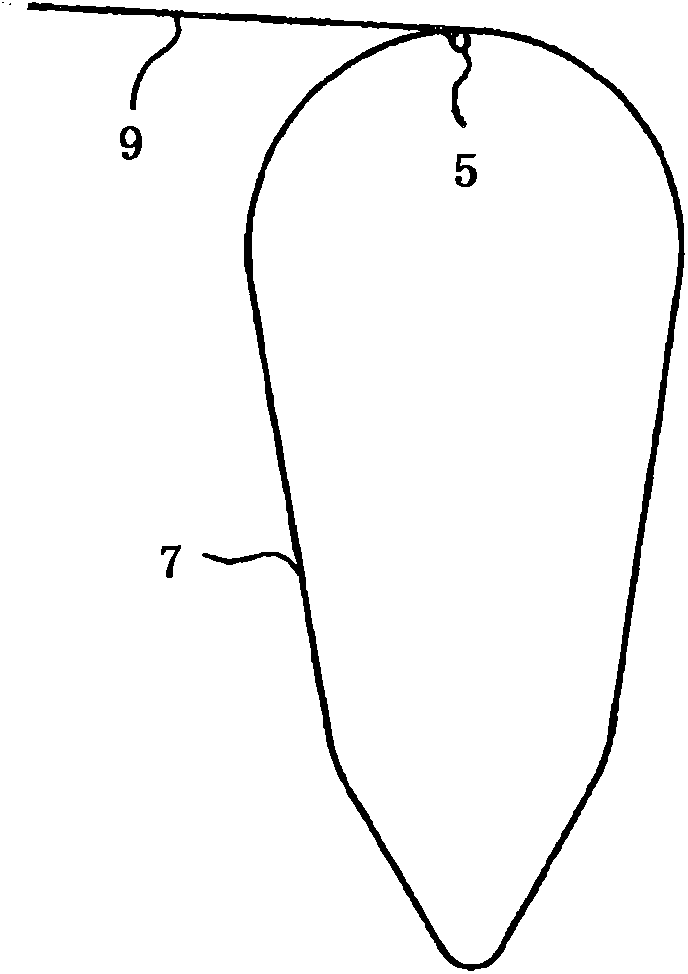

[0033] Figure 1a shows a single coil element 15 according to the invention viewed from the front, while Figure 1b The coil element 15 is shown viewed from the side, wherein the slots 1 - 4 for receiving an adjacent coil element 15 and the connection pins 5 , 6 are shown. For the sake of clarity, the flat wire 9 forming the coil is not shown in FIG. 1 .

[0034] The coil element consists of several windings of a continuous flat insulated wire 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com