Device and method for detecting panel strip shapes

A plate and plate shape technology, which is applied in the field of dynamic plate shape detection devices, can solve the problems of the influence of the shape detection accuracy and the inability to meet the requirements of the metal plate shape detection accuracy, etc., and achieves a simple structure, reliable operation, high The effect of measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

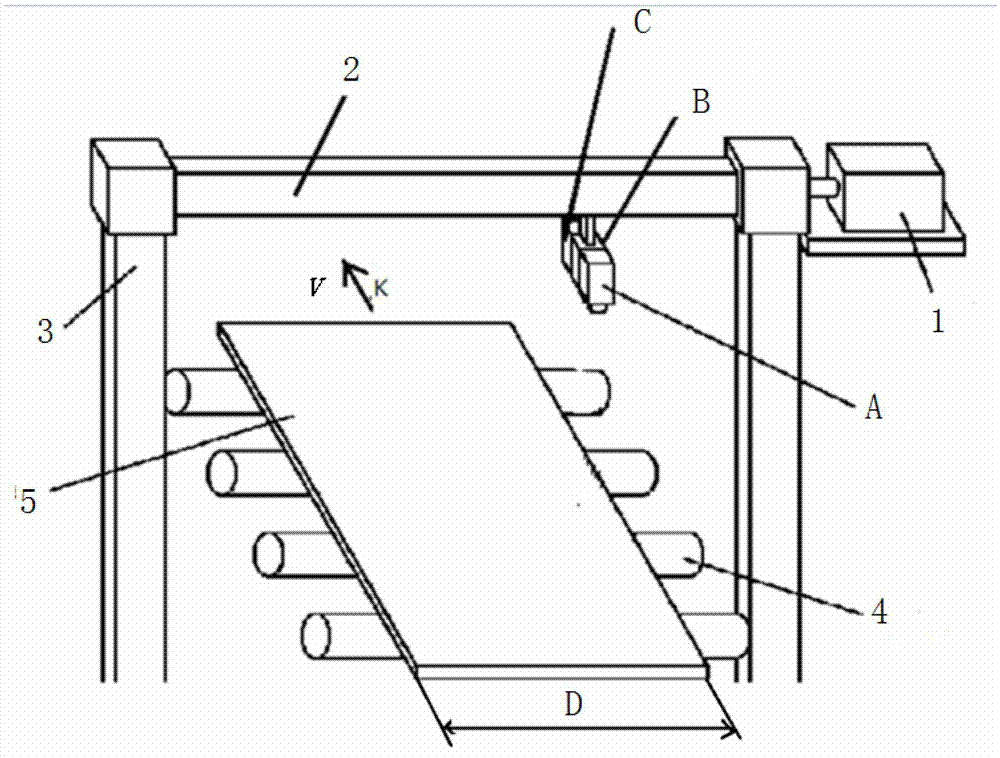

[0022] 1. If figure 1 As shown, the width D of the plate 5 is now 0.35m, and it is transported on the conveying roller table 4, and the frame 3 is installed across the conveying roller table 4. 1. The second and third rangefinders A, B and C. The distance T between the probes of the three rangefinders is 0.05m. The direction of the track below the upper beam 2 is perpendicular to the forward direction of the plate. The three range finders are controlled by stepping motors and can reciprocate in the track below the upper beam 2 according to the width D of the plate.

[0023] 2. When a plate with a width of 0.35m advances on the conveying roller table at a speed of 1m / s, the three rangefinders are controlled by a stepping motor to reciprocate directly above the plate at a speed of u=2DV / T=14m / s Movement, the stroke of one reciprocation is 0.7m. The range finder measures 20 points on the middle line of plate 5 (point X 1 ~X 20 ) the vertical distance from the range finder, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com