Movable oilfield nitrogen making liquefaction device

A liquefaction device and mobile technology, applied in the field of mobile oilfield nitrogen liquefaction devices, can solve the problems of inability to achieve continuous production, inconvenient use, lack of availability, etc., and achieve the effects of convenient on-site movement, compact use performance and compact device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

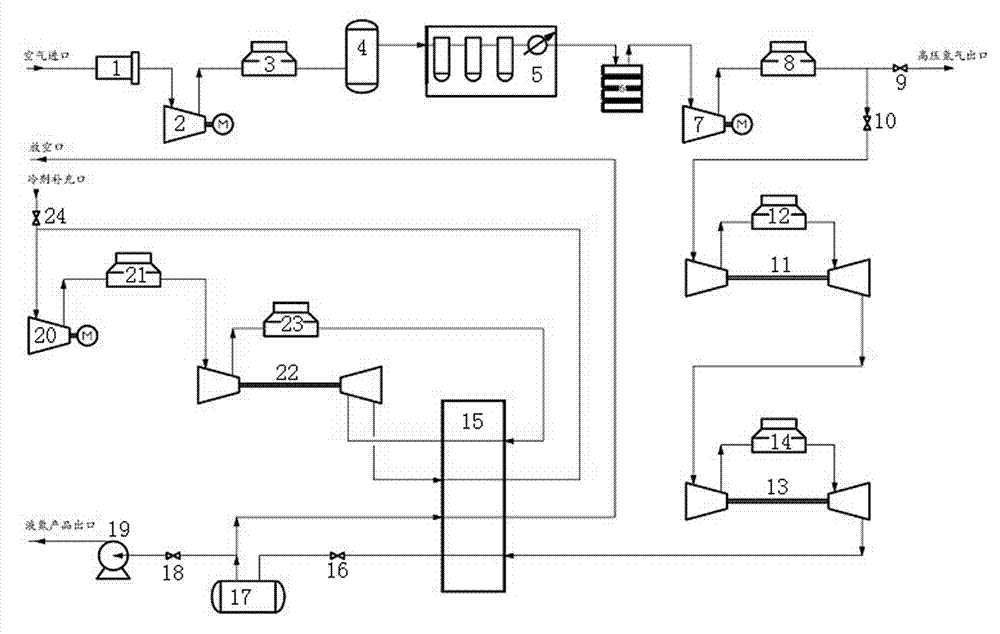

[0013] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

[0014] Such as figure 1 As shown, a mobile oilfield nitrogen liquefaction device of the present invention first starts the air screw compressor 2, and the air in the atmosphere enters the air screw compressor 2 through the air filter 1, and the air is compressed and boosted to 2.4MPa, and the compressed gas It is first cooled by the aluminum-fin air-cooled cooler 3, then enters the steam-water separation tank 4 to remove water, and then is filtered and purified by a pretreatment device 5 such as a filter, so that the purity of the compressed gas can reach a particle size content of less than 0.01um and an oil mist content of less than 0.01 The purity index of ppm then enters the hollow fiber membrane 6 to realize nitrogen-oxygen separation. The separated nitrogen enters the nitrogen piston booster 7 and is compressed to 35MPa to become high-pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com