Carbon dioxide overlapping-type commercial refrigeration system

A carbon dioxide and refrigeration system technology, applied in refrigerators, refrigeration and liquefaction, lighting and heating equipment, etc., can solve the problems of large refrigerant charge, low energy efficiency of refrigeration units, poor environmental protection performance, etc., to reduce volume and energy low energy consumption, easy to realize automation, and good energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

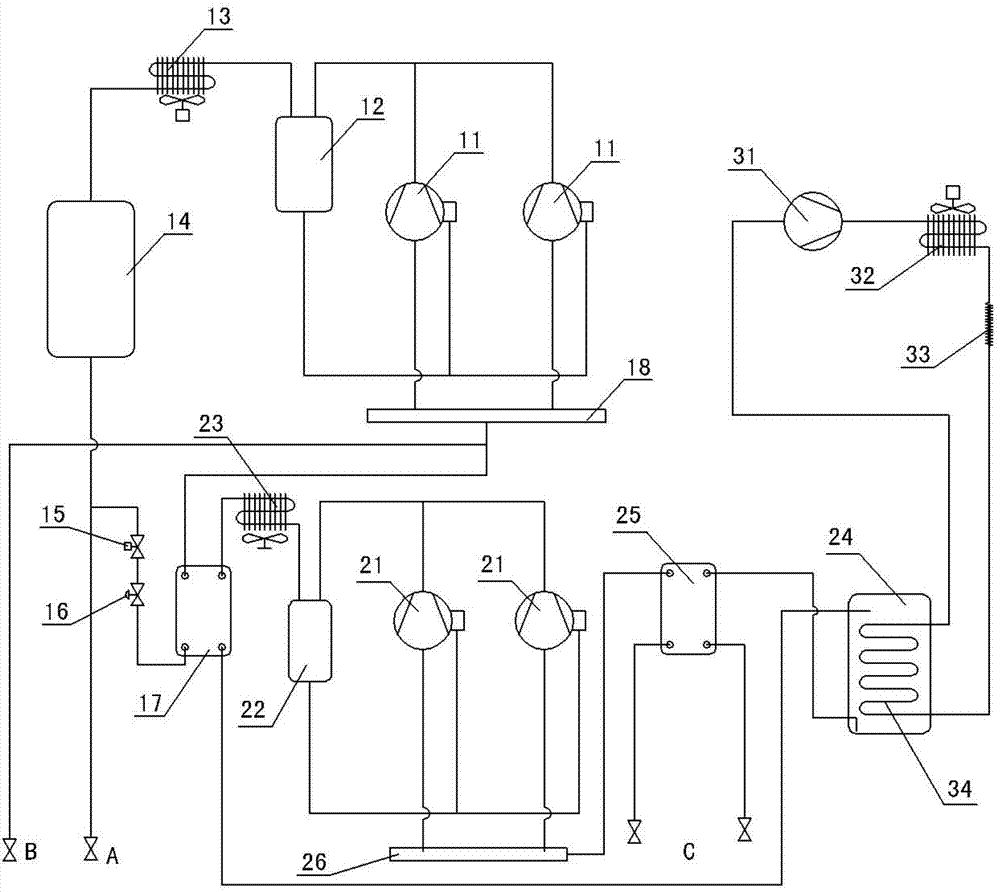

[0022] See figure 1 The structure of the carbon dioxide cascade commercial refrigeration system in this embodiment is:

[0023] The high-temperature stage circuit is set as follows: each high-temperature refrigeration compressor 11 is connected in parallel, the exhaust manifold of each high-temperature refrigeration compressor 11 is connected to the first oil separator 12, and the lubricating oil outlet oil pipe of the first oil separator 12 is connected to the high-temperature stage The crankcase of the refrigeration compressor 11, the refrigerant gas outlet of the first oil separator 12 is connected to the inlet of the first air-cooled condenser 13, and the refrigerant liquid outlet of the first air-cooled condenser 13 is connected to the high-temperature accumulator The inlet of 14 and the outlet of the high-temperature accumulator 14 are divided into two outputs. One of the outputs A provides a cold source for refrigeration users, and the other output is connected to the evap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com