Wear resistant sole material

A technology of shoe sole materials and raw materials, which is applied in the field of wear-resistant shoe sole materials, can solve the problems of reduced strength of samples, poor compatibility, and poor grip of the combination of abrasive grains and rubber, and achieve the effect of improving wear resistance and excellent rebound performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

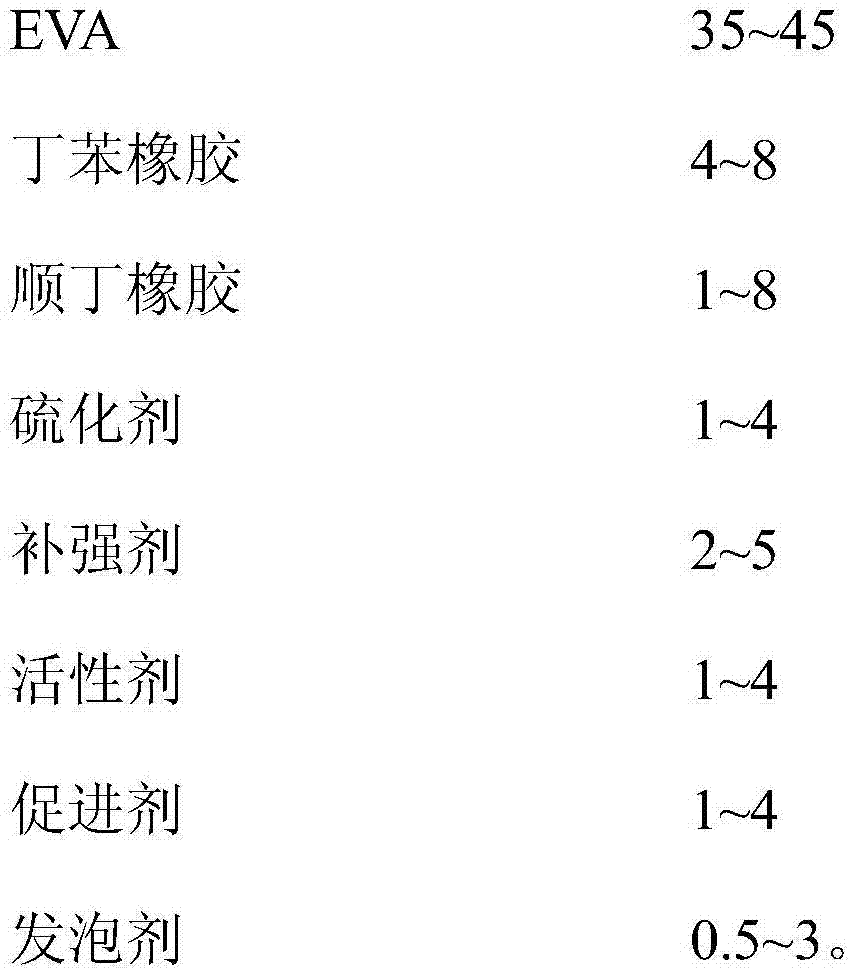

[0030] A wear-resistant shoe sole material, which comprises the following raw materials in parts by weight:

[0031]

[0032] The vulcanizing agent is sulfur.

[0033] Described active agent selects stearic acid for use.

[0034] The reinforcing agent is selected from carbon black N234.

[0035] The accelerator is selected from a mixture of accelerator CZ and accelerator TMTD.

[0036] The foaming agent is DX-74MT medium temperature foaming agent.

Embodiment 2

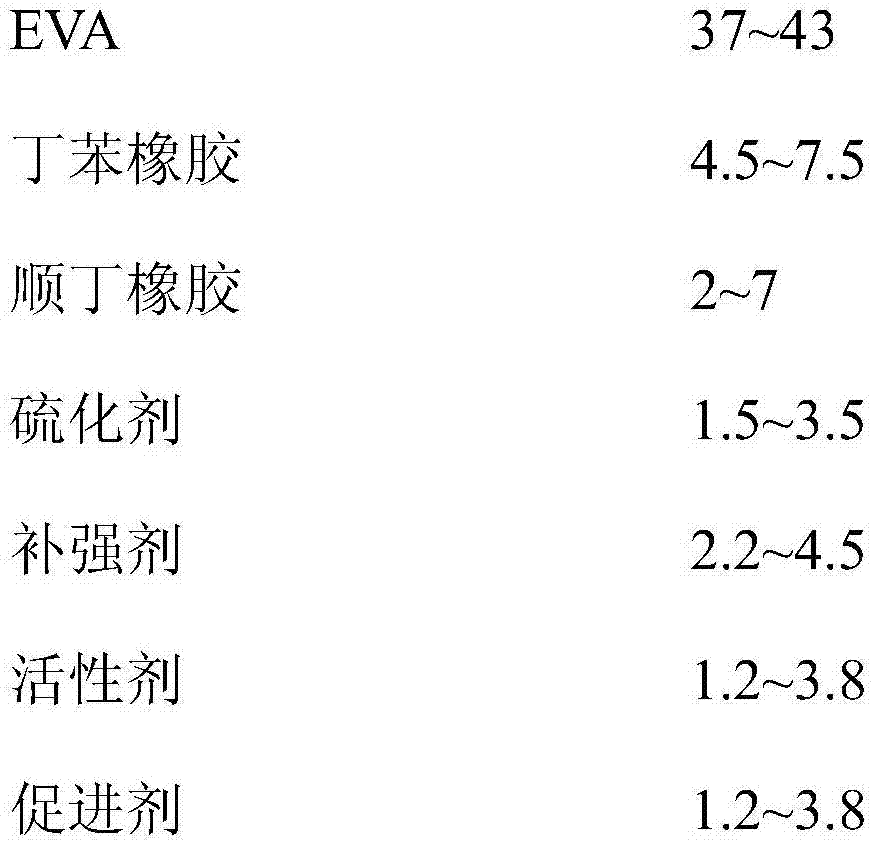

[0038] A wear-resistant shoe sole material, which comprises the following raw materials in parts by weight:

[0039]

[0040] The vulcanizing agent is sulfur.

[0041] Described active agent selects zinc stearate for use.

[0042] The reinforcing agent is selected from a mixture of carbon black N234, carbon black N220 and carbon black N330.

[0043] The accelerator is selected from accelerator CZ.

[0044] The foaming agent is DX-74MT medium temperature foaming agent.

Embodiment 3

[0046] A wear-resistant shoe sole material, which comprises the following raw materials in parts by weight:

[0047]

[0048]

[0049] The vulcanizing agent is sulfur.

[0050] Described active agent selects stearic acid and zinc stearate for use.

[0051] The reinforcing agent is selected from carbon black N330.

[0052] The accelerator is selected from accelerator DZ.

[0053] The foaming agent is DX-74MT medium temperature foaming agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com