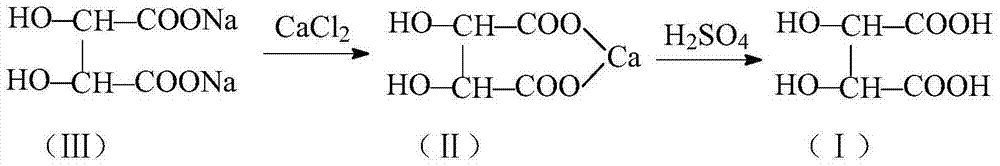

Method for recovering and preparing L(+)-2, 3-dihydrobutanedioic acid from L-methyldopa production wastewater

A technology of dihydroxysuccinic acid and calcium hydroxysuccinate, applied in carboxylate preparation, organic chemistry, etc., can solve problems such as environmental pollution and waste of resources, and achieve the effects of stable process, easy control and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Add 2400kg of L-methyldopa production wastewater containing 5% L(+)-2,3-dihydroxysuccinate sodium (Ⅲ) to a 3000L reactor, start stirring, and add 84kg of dihydroxysuccinate at 20°C Calcium chloride water, stirred for 30 minutes, a large amount of solids precipitated, continued to stir for 30 minutes, cooled to 10°C, discharged and centrifuged to obtain 111.6kg L(+)-2,3-dihydroxysuccinate calcium (Ⅱ) solid wet Taste;

[0029] (2) Add 200kg of water and 100kg of L(+)-2,3-dihydroxysuccinate calcium (II) to the reactor, slowly add 183.3kg of 30% sulfuric acid aqueous solution under stirring, stir for 30min, and filter out the sulfuric acid Calcium, add 1.6kg of activated carbon to the filtrate and raise the temperature to 60°C for decolorization for 30 minutes, filter while it is hot, concentrate the filtrate under reduced pressure to 0.6 times the amount of water added, then cool the concentrated solution to crystallize at 0°C, centrifuge and wash to obtain 71.8kgL(+)-...

Embodiment 2

[0032] (1) Add 2400kg of L-methyldopa production wastewater containing 10% compound (Ⅲ) to a 3000L reactor, start stirring, add 240kg of calcium chloride dihydrate at 0°C, stir for 10 minutes, and a large amount of solids precipitate out. Stirring was continued for 30 minutes, the temperature was lowered to 8°C, and the material was discharged and centrifuged to obtain a solid wet product containing 230.2kg of compound (II).

[0033] (2) Add 200kg of crude mother liquor and 100kg of compound (II) to the reaction kettle, slowly add 183.3kg of 30% sulfuric acid aqueous solution under stirring, stir and react for 30min, filter out calcium sulfate, add 4kg of activated carbon to the filtrate and heat up to 65°C for decolorization for 30min , filtered while it was hot, and the filtrate was concentrated under reduced pressure to 0.4 times the amount of the crude mother liquor, then the concentrated solution was cooled to crystallize at 5°C, centrifuged, washed, and 99.4kg of crude co...

Embodiment 3

[0036] (1) Add 2400kg of L-methyldopa production wastewater containing 5% compound (Ⅲ) to a 3000L reactor, start stirring, add 60kg of calcium chloride dihydrate at 60°C, and stir for 60 minutes, a large amount of solids are precipitated. Stirring was continued for 30 minutes, the temperature was lowered to 12°C, and the material was discharged and centrifuged to obtain a solid wet product containing 113.3kg of compound (II).

[0037] (2) Add 100kg of refined mother liquor and 100kg of compound (II) into the reaction kettle, slowly add 300kg of 20% sulfuric acid aqueous solution under stirring, stir for 30min, filter out calcium sulfate, add 2.8kg of activated carbon to the filtrate and heat up to 100°C for decolorization for 10min, Filtrate while hot, and concentrate the filtrate under reduced pressure to 0.2 times the amount of the refined mother liquor, then cool the concentrated solution to crystallize at 0°C, centrifuge and wash to obtain 99.8kg of crude compound (I).

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com