Efficient brick setting machine

A brick stacking machine and high-efficiency technology, applied in the field of brick stacking machines, can solve the problems of easily damaged brick corners and low work efficiency, and achieve the effects of reducing edge damage, improving efficiency, and shortening stacking time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

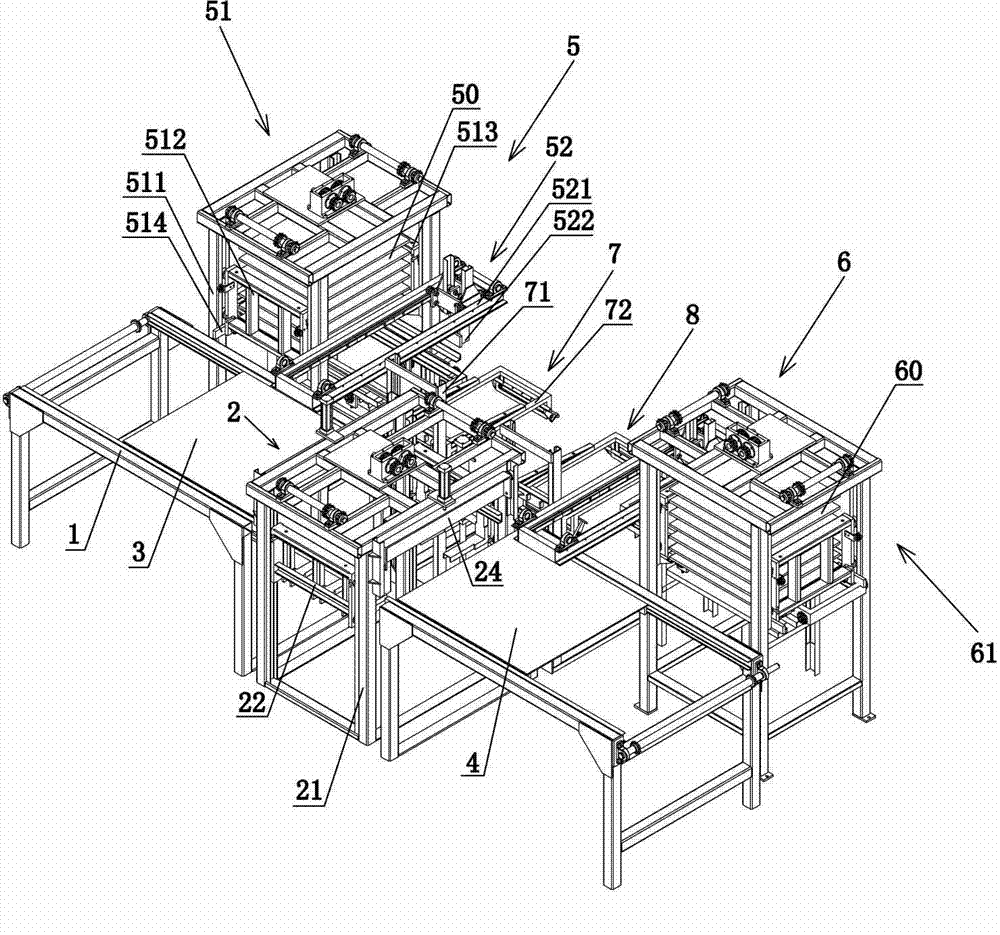

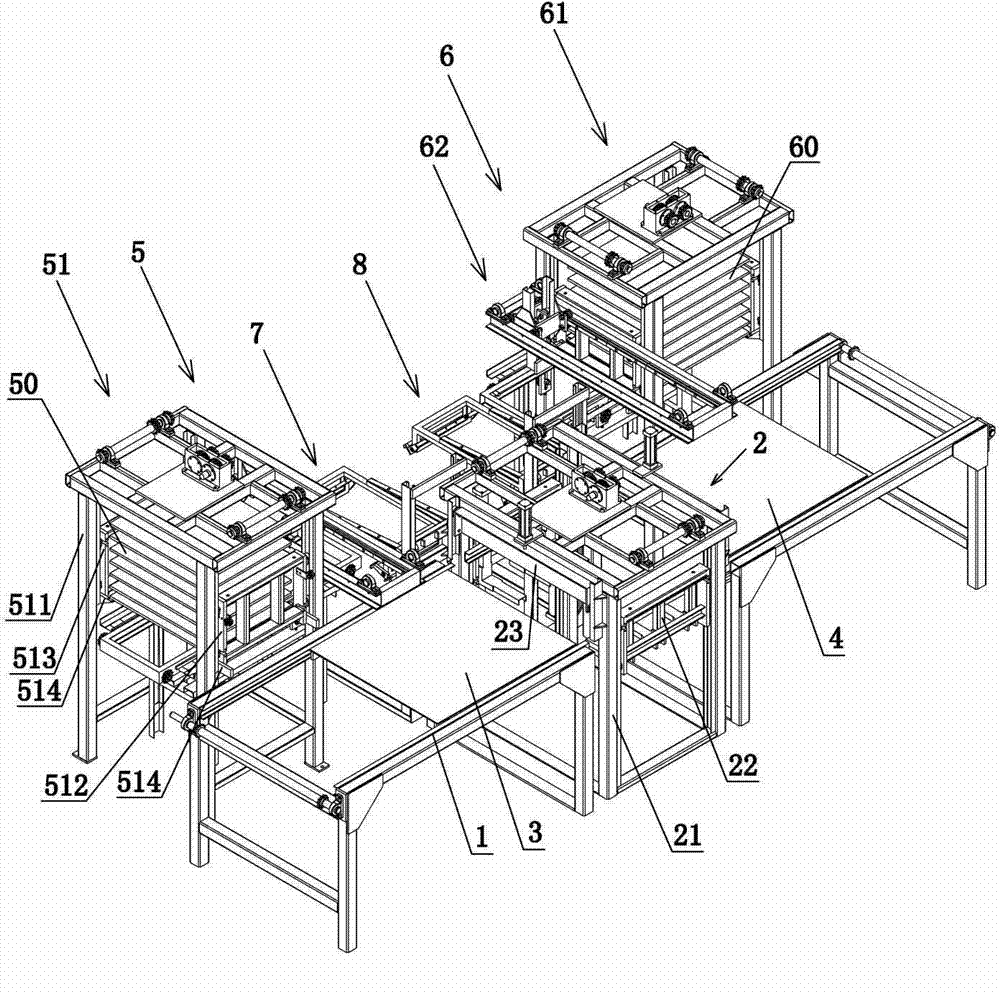

[0020] refer to figure 1 with figure 2 . An efficient and efficient brick stacking machine includes a frame 1, a carrier plate that can slide on the frame 1 and is used to carry bricks, and a collecting device 2 for collecting bricks on the carrier plate, the carrier plate includes The first carrier plate 3 for carrying bricks placed horizontally and the second carrier plate 4 for carrying bricks placed vertically, one side of the first carrier plate 3 is provided with a To the first brick feeding device 5 of the first carrier 3, one side of the second carrier 4 is provided with a second brick feeding device 6 for sending the bricks vertically placed on it to the second carrier 4, the The first carrier board 3 and the second carrier board 4 are respectively located on the left and right sides of the collecting device 2 .

[0021] refer to figure 1 with figure 2 . The first brick feeding device 5 includes a first brick-laying mechanism 51 with multiple layers of first b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com