Feeding mechanism of automatic low-level palletizer

A feeding mechanism and low-level code technology, which is applied in the stacking, transportation and packaging of objects, can solve the problems of less bricks, high labor intensity and low loading efficiency, and achieve shortened time and high stacking efficiency. , the effect of low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

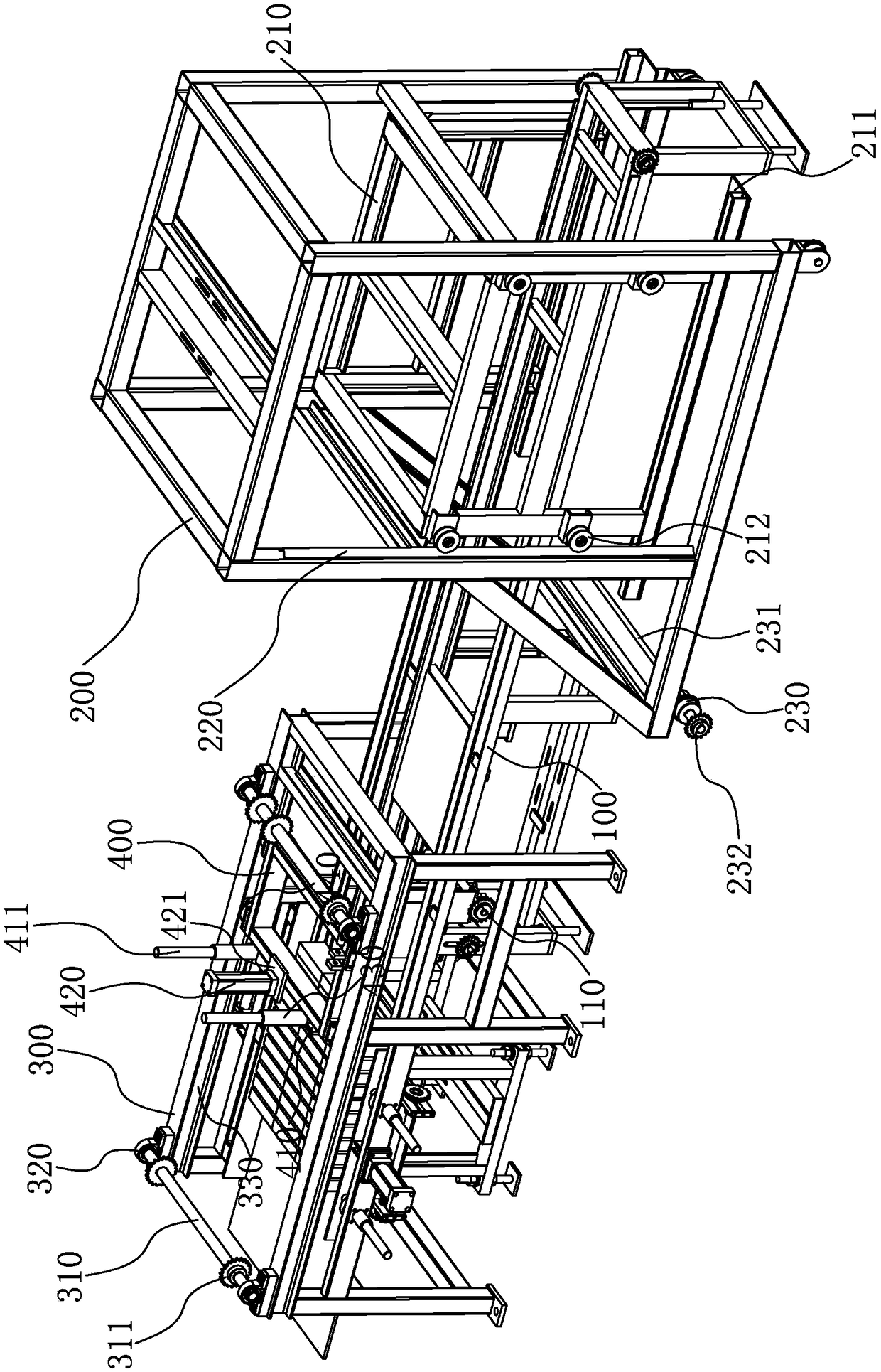

[0036] Such as figure 1 As shown, the feeding mechanism of the automatic low-level palletizer of the present invention includes a feeding frame 100, a feeding assembly, a discharging frame 300 and a pushing assembly.

[0037] The feeding frame 100 is a frame structure, which is arranged in the axial direction and has a feeding end and a discharging end.

[0038] The feeding assembly includes a moving frame 200 and a feeding frame 210. The moving frame 200 is a frame structure. The moving frame 200 can move axially relative to the feeding frame 100 and can move to the top of the feeding frame 100. The feeding frame 210 is also a frame structure. , which is arranged inside the moving frame 200 and can move vertically relati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com