Automatic plate stacking control device for rock wool and control method of automatic plate stacking control device

A technology of control device and rock wool board, applied in the direction of conveyor control device, optical device, measuring device, etc., can solve the problems that various special-shaped boards cannot be sorted and stacked, cannot produce multiple varieties, and low utilization rate, etc., to achieve Correct corner correspondence, good transportation classification, convenient cutting and packaging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

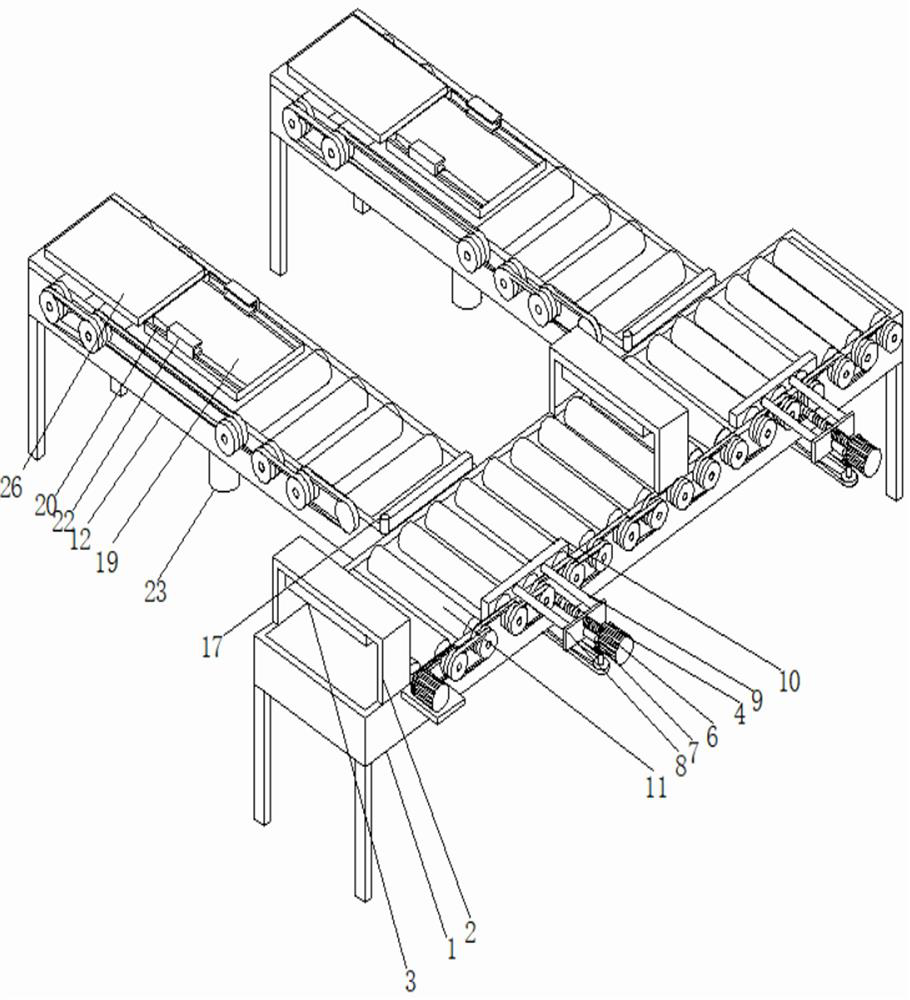

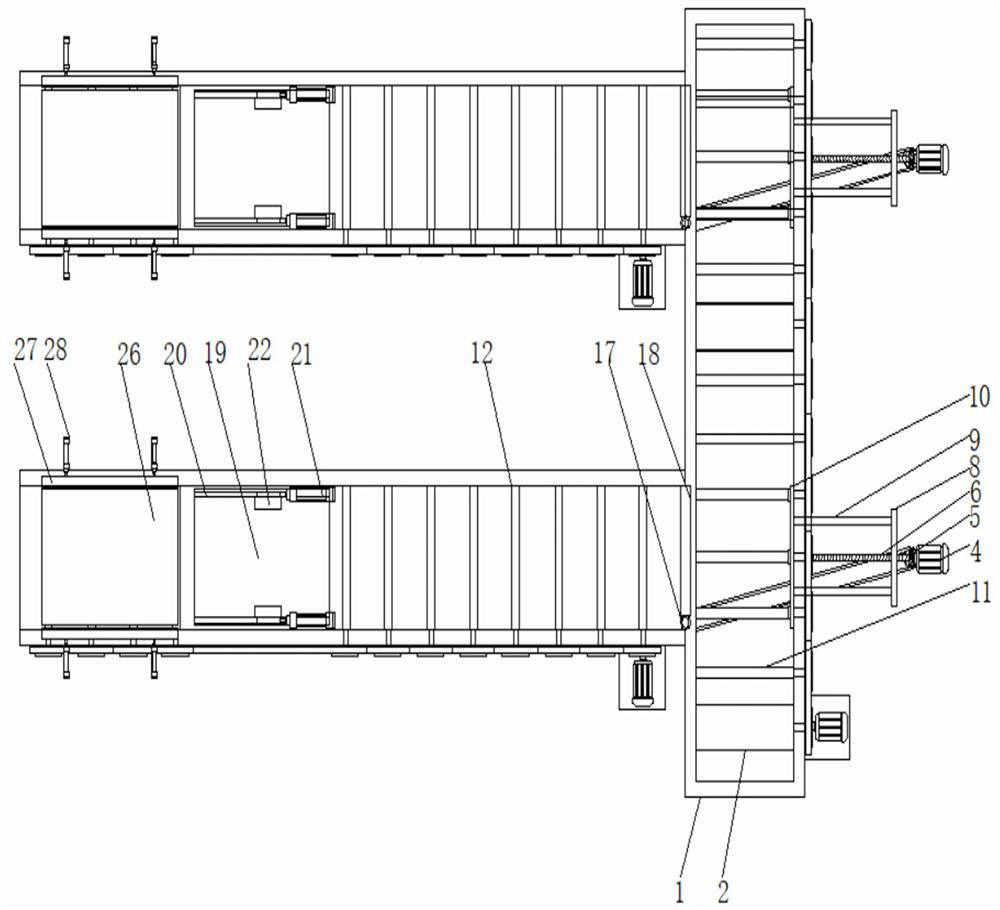

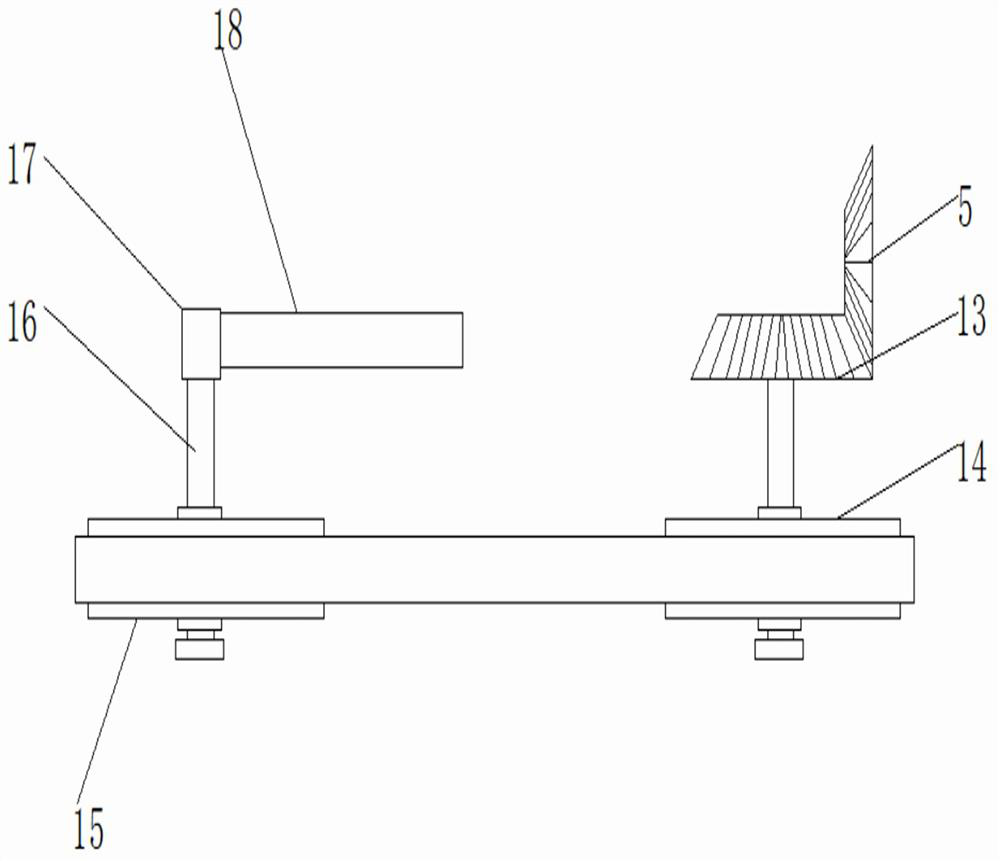

[0031] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. The embodiments described below with reference to the accompanying drawings are exemplary, only used to explain the present invention, and should not be construed as a limitation of the present invention.

[0032] The embodiments of the present invention will be described below based on the overall structure of the present invention.

[0033] see Figure 1-6, an automatic stacking control device for rock wool and a control method thereof, comprising a first roller bed 1, the top of the first roller bed 1 is connected with a mounting frame 2, the first roller bed 1 includes a drive motor, a driving wheel, a slave The driving wheel and the rotating roller 11, and the driving wheel is located at the output end of the driving motor, the driven wheel is located on one side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com