Stamping method

A seal and roller technology, applied in the field of stamping, can solve the problems of not being able to stamp alone, poor versatility, and large footprint of the machine, and achieve the effects of easy large-scale promotion, low noise, and short work time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

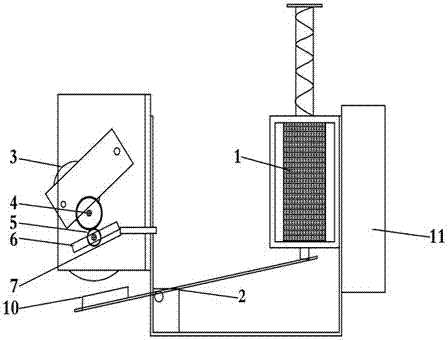

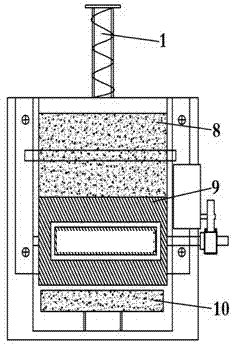

[0020] (1) A general-purpose stamping module based on a single-chip microcomputer is set, and a U-shaped bracket with a distance of 100 millimeters between the front and rear walls is a supporting frame, including an electromagnet 1, a lever mechanism 2, a stepping motor 3, a stepping motor gear 4, Stamp roller gear 5, stamp roller 9, ink storage roller 8, photoelectric module 7, shading sheet 6, stamp supporting plate 10 and cooling fan 11, electromagnet 1 is fixed on the back wall of U-shaped bracket by screws, and the lower end of electromagnet 1 is separated from The bottom of the U-shaped bracket is 40 mm, and there is a rectangular hole with a length of 70 mm × a height of 30 mm along the bottom edge just below the front wall of the U-shaped bracket. The bracket supporting plate of the lever mechanism 2 passes through this hole, and under the action of the lever mechanism 2 Move up and down, the front wall of the U-shaped bracket is fixed with two steel plate brackets wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com