Autonomous mobile robot for welding in narrow space

An autonomous mobile and robotic technology, applied in the field of robotics, can solve the problems that large-sized workpieces cannot be welded, smoke and dust are difficult to discharge, and workpieces are difficult to adapt to, etc., to improve driving force and stability, prevent falling damage, and small dimensions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

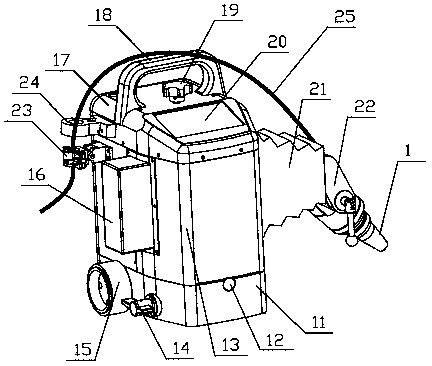

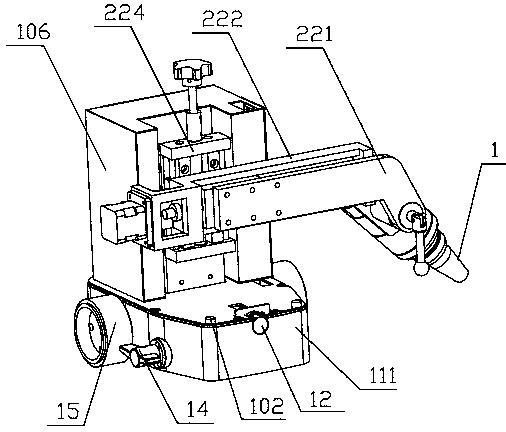

[0045] With reference to the drawings, the description is as follows: The autonomous mobile robot for welding in narrow spaces of the present invention includes: a robot body, a rotating scanning welding torch and a control system; the robot body includes a robot chassis, a welding torch adjusting device, and a welding cable fixing device , Motor cover, body cover, handle and dust cover; the control system includes a sensor, a controller and a touch screen; the rotary scanning welding torch is installed on the welding torch adjusting device through bolts, and the welding torch rotates at a constant speed during the welding process The pulse signal is generated by the optical code disc to provide the sampling trigger signal for the controller.

[0046] The robot chassis includes a driving device, a guide wheel, an adjustable permanent magnet gap adsorption device and a body installed with the above device; the robot chassis adopts a three-wheel differential drive structure, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com