Equipment and process for manufacturing belt in quenching mode

A technology of cold production and equipment, which is applied in the field of quenching strip production equipment and technology, which can solve the problems of low speed, unsuitable for thin strip and ultra-thin strip production test, and cast strip thickness, so as to achieve easy control of performance and improve cooling effect , Improve the effect of success rate and operation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

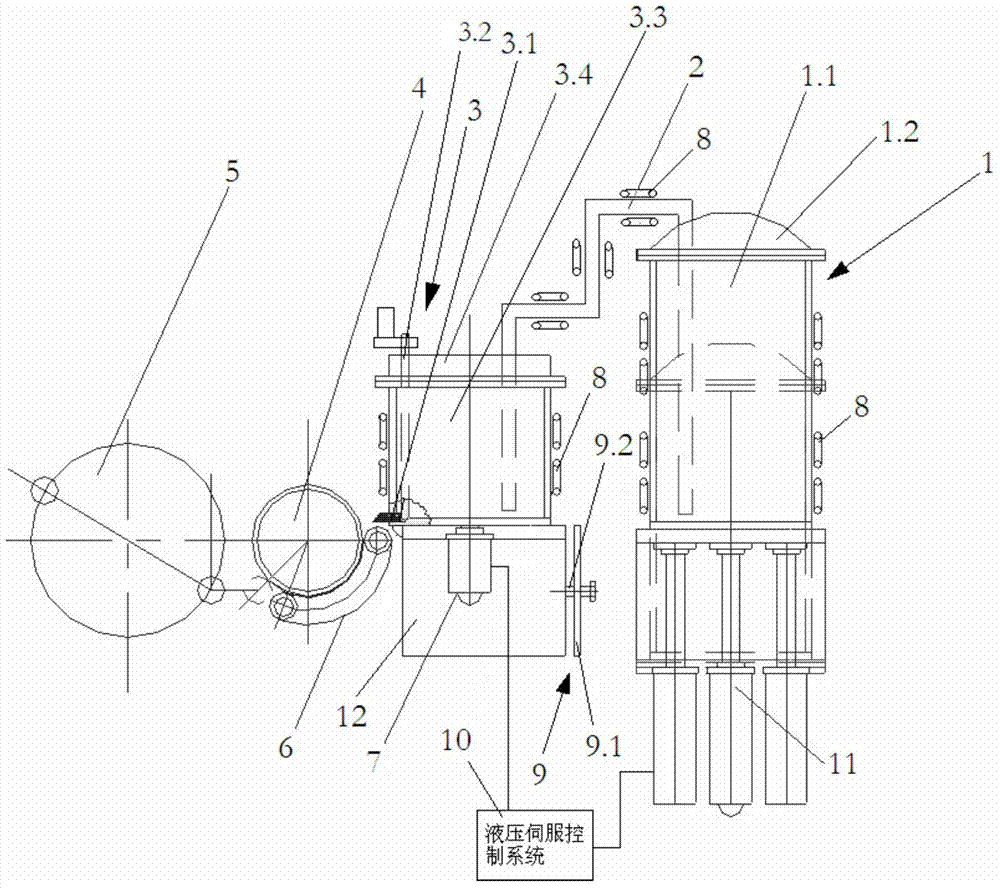

[0035] figure 1 The shown quenching belt-making equipment includes a first hydraulic cylinder 11, a siphon 2, a magnetic coiler 5, a cooling roller 4, a cooling crawler belt 6 matched with the cooling roller 4, and a lifting type that can be lifted and lowered by the hydraulic cylinder 11. The tundish 1, the nozzle package 3 communicated with the liftable tundish 1 through the siphon tube 2, the base 12 arranged at the bottom of the nozzle package 3, the second nozzle package arranged between the nozzle package 3 and the base 12 and capable of driving the nozzle package 3 to lift Hydraulic cylinder 7, wherein a cooling channel is formed between the cooling roller 4 and the cooling track 6, the nozzle 3.1 of the nozzle package 3 corresponds to the entrance of the cooling channel, the magnetic reel of the magnetic coiler 5 corresponds to the outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com