Double-action double-angle side shaping mechanism

A double-angle, side shaping technology, which is applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems that parts cannot be taken out, and the problem of concave surface forming cannot be solved, so as to save mold costs, save the number of machine tools, save The effect of the number of processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

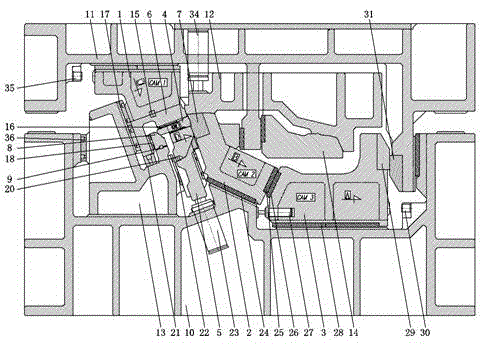

[0014] Such as figure 1 As shown, the cross-sectional structural schematic diagram of the double-action double-angle side shaping mechanism installed on the pressure plate. Its structure includes: upper mold driving part and movable punch working part. The front end of the upper mold base 11 is provided with an upper plug-in guide plate 31, and the rear side is a vertical surface, on which a mounting surface is provided to install the guide plate. The upper plug-in guide plate 31 drives the drive slider 3 to work in the negative direction of A, and the guide slide surface is the drive slider 3 The lower plug-in guide plate 29 of upper installation. The auxiliary guide surface is the seventh wear plate 28 installed on the lower mold base 10 . The sixth wear-resistant plate 26 installed on the drive slider 3 drives the movable punch slider 2 to work in the B negative direction. The sliding surface is the fifth wear plate 25 installed on the movable punch slider 2 . One of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com