Feed rich in conjugated linoleic acid and preparation method of feed

A conjugated linoleic acid and feed technology, applied in animal feed, animal feed, application and other directions, can solve the problem of high production cost, achieve good palatability, rich and balanced amino acids, and promote the growth of livestock and poultry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

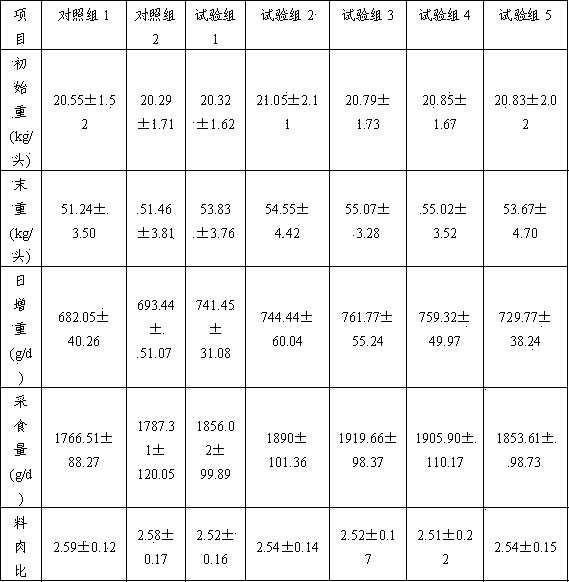

Examples

Embodiment 1

[0025] Mix 6kg of perilla seed powder and 4kg of corn flour evenly, then add 40kg of molasses, 5kg of sunflower oil and 150kg of clean water to prepare a fermentation broth, raise the temperature to 95°C, soak and sterilize for 4 hours, then cool down until the temperature drops to 36°C Add 12kg of Lactobacillus plantarum seed solution at ℃, control the pH value at 7.0, and mix in 200kg of corn flour, 30kg of soybean meal powder, 30kg of bran, 20kg of sunflower oil and 10kg of 4% premix after the first liquid fermentation for 96 hours. After 72 hours of secondary solid-state fermentation, dry at low temperature to make solid fermented feed rich in conjugated linoleic acid.

Embodiment 2

[0027] Mix 50kg of perilla seed powder and 50kg of corn flour evenly, then add 350kg of molasses, 50kg of sunflower oil and 1600kg of clean water to prepare a fermentation broth, raise the temperature to 95°C, soak and sterilize for 4 hours, then cool down, and wait until the temperature drops to 37°C Add 150kg of Lactobacillus plantarum seed solution at ℃, control the pH value at 6.5, and after the first liquid fermentation for 96 hours, mix 2000kg of corn flour, 300kg of soybean meal powder, 200kg of bran, 100kg of sunflower oil and 80kg of 4% premix, and then add After secondary solid-state fermentation for 96 hours, dry at low temperature to make solid fermented feed rich in conjugated linoleic acid.

Embodiment 3

[0029] Mix 100kg of perilla seed powder and 20kg of corn flour evenly, then add 100kg of molasses, 20kg of sunflower oil and 1500kg of clean water to prepare a fermentation broth, raise the temperature to 95°C, soak and sterilize for 4 hours, then cool down until the temperature drops to 37 Add 120kg of Lactobacillus plantarum seed solution at ℃, control the pH value at 5.5, and mix 1800kg of corn flour, 250kg of soybean meal powder, 300kg of bran, 100kg of sunflower oil and 80kg of 4% premix after the first liquid fermentation for 96 hours. After secondary solid-state fermentation for 96 hours, dry at low temperature to make solid fermented feed rich in conjugated linoleic acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com