Method and device for detecting termination of etching

A detection method and etching technology, which are applied in microstructure devices, manufacturing microstructure devices, and microelectronic microstructure devices, etc., can solve problems such as inability to correctly detect the completion of etching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

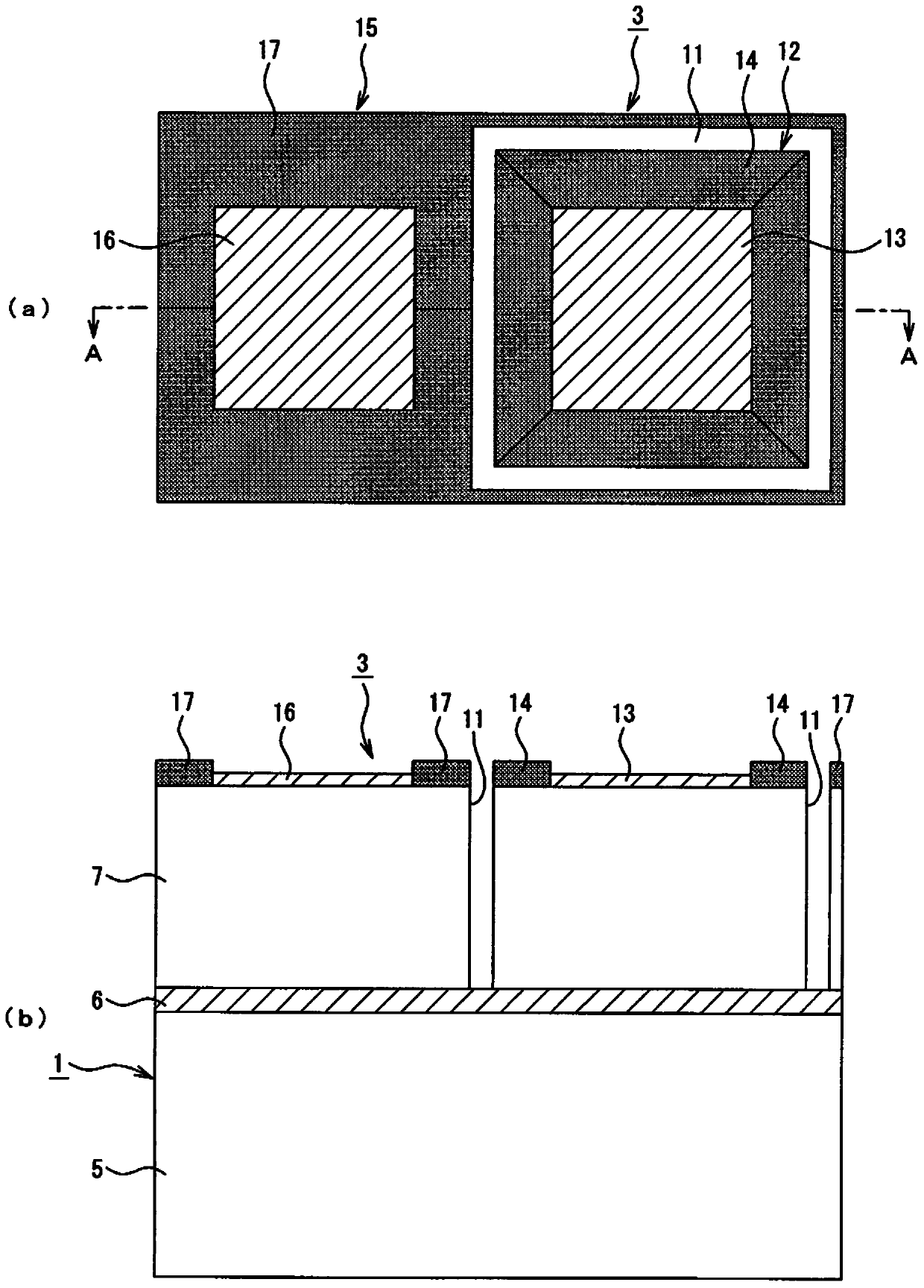

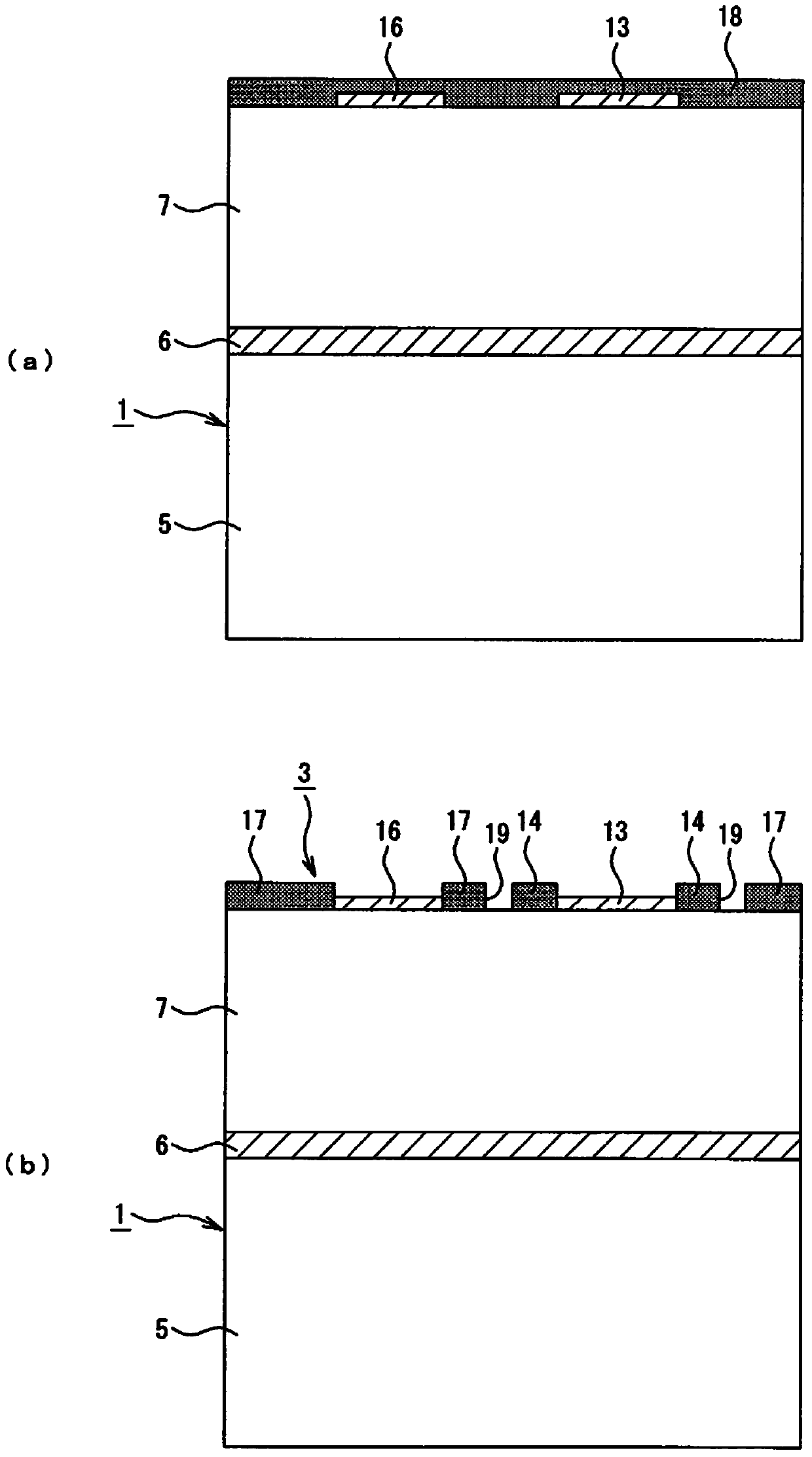

[0059] Embodiments of the present invention will be described below with reference to the accompanying drawings.

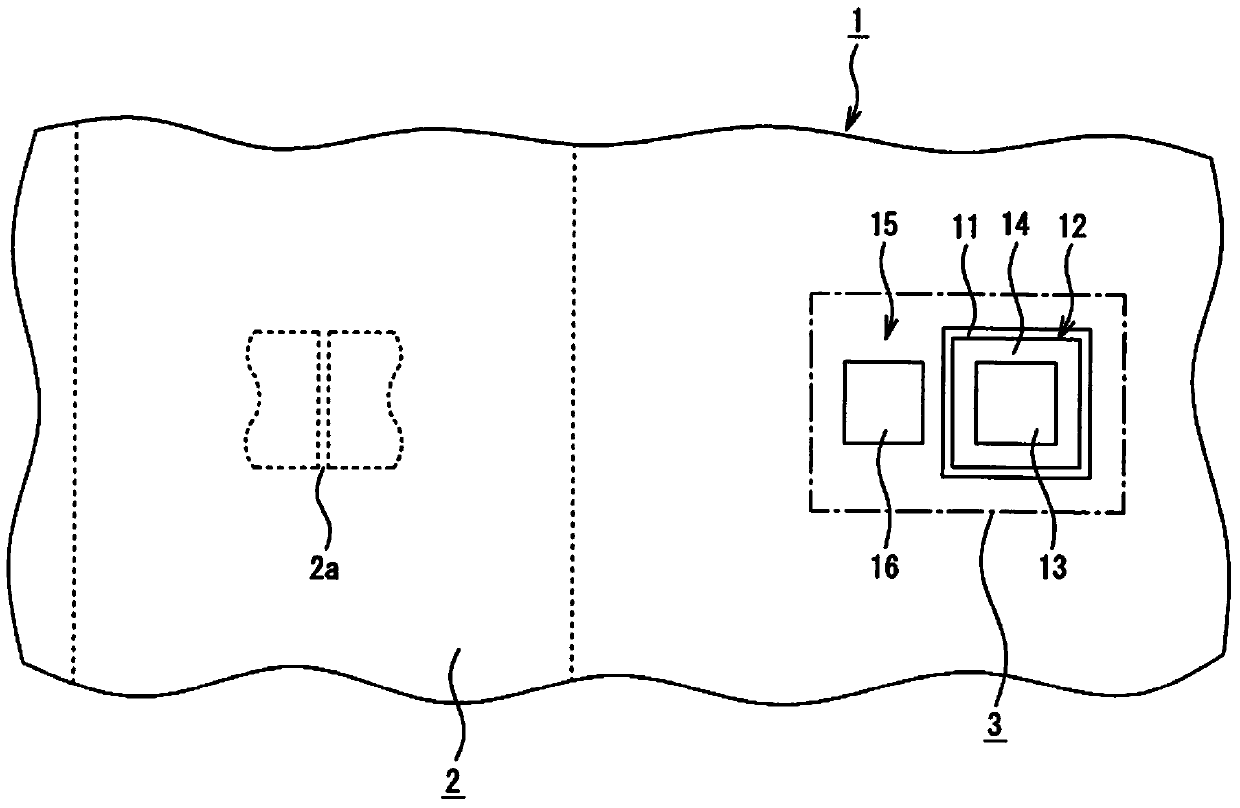

[0060] figure 1 It is a plan view of an SOI (Silicon On Insulator) substrate suitable for the etching method of the present invention.

[0061] In the figure, 1 is an SOI substrate. On this SOI substrate 1, various oscillators such as pressure sensors, acceleration sensors, angular velocity sensors, and attitude sensors for MEMS (Micro Electro Mechanical System) applications are formed. A part 2, and an etching completion detection part 3 formed separately from the part 2 to be processed.

[0062] Such as figure 2 As shown in (b), in this SOI substrate 1 , an etch stop layer 6 serving as an insulating layer is formed on a base material 5 , and an etched layer 7 is formed on this etch stop layer 6 . Here, the main material of the substrate 5 and the layer to be etched 7 is silicon, and has a low resistance characteristic with a specific resistance of about 0.01...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com